Device and method for testing and calibrating microwave chip

A microwave chip and microstrip line technology, which is applied in the field of microwave chip test and calibration devices, can solve problems such as inability to connect chips and inaccurate test results, and achieve the effects of stable and reliable test data, improved anti-interference ability, and large grounding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail through specific embodiments below, but these embodiments are only for illustration and do not limit the scope of the present invention.

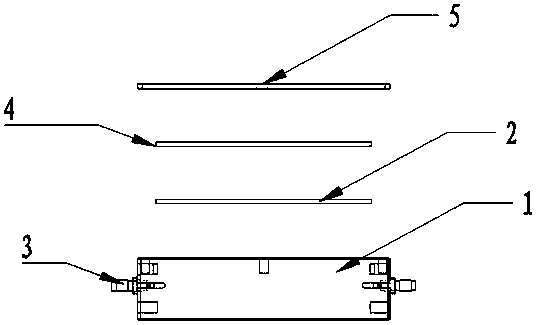

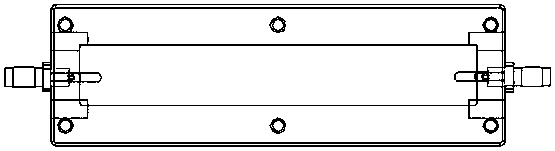

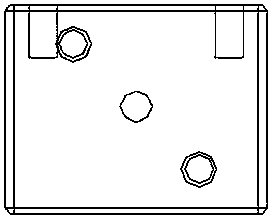

[0018] Please refer to Figure 1 to Figure 5 , the device for testing and calibrating microwave chips of the present invention comprises: a base, a wave-absorbing material, a cover plate, a cavity with an opening is arranged on the upper end surface of the base, a printed circuit board is placed in the cavity, and the two sides of the base are installed The radio frequency connector SMA, the printed circuit board is connected to the SMA joints arranged on both sides of the base, the absorbing material is sealed in the cavity, and the absorbing material is bonded to the cover plate and fixed on the upper surface of the base.

[0019] In one embodiment, the cover plate is connected to the base by screws.

[0020] In one embodiment, the SMA connector is disposed through mounting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Line width | aaaaa | aaaaa |

| Line length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com