A lightweight carriage plate and a preparation method thereof

A carriage panel and lightweight technology, which is applied to chemical instruments and methods, vehicle components, and the upper structure of trucks, etc., can solve the problems of low bonding strength of carriage panels, substandard overall strength, and short service life, and achieve Excellent sound insulation and heat insulation performance, stable and controllable weight, and the effect of reducing the load weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

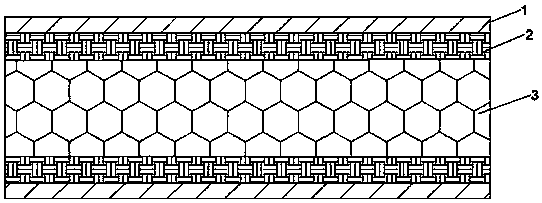

[0024] Such as figure 1 As shown, a lightweight compartment panel includes a gel coat layer 1 , an outer skin layer 2 and an inner core layer 3 . The outer skin layer 2 is installed on both sides of the inner core layer 3 . The gel coat layer 1 is installed on both sides of the outer skin layer 2 . The outer skin layer 2 is made of fiberglass. The inner core layer 3 has a honeycomb structure. The inner core layer is made of PP material. The thickness of the outer skin layer is 1mm. The thickness of the inner core layer is 10mm.

[0025] A method for preparing a lightweight car panel, the steps are as follows:

[0026] S1. Take two flat molds, clean them, and then treat the clean two flat molds with a release material, then spray the gel coat evenly on the flat molds, and finally send the flat molds into the press for heating and curing. The heating and curing time of the flat mold is 30 minutes. Use masking paper to circle the area where the length and width of the pre...

Embodiment 2

[0032] Such as figure 1 As shown, a lightweight compartment panel includes a gel coat layer 1 , an outer skin layer 2 and an inner core layer 3 . The outer skin layer 2 is installed on both sides of the inner core layer 3 . The gel coat layer 1 is installed on both sides of the outer skin layer 2 . The outer skin layer 2 is made of fiberglass. The inner core layer 3 has a honeycomb structure. The inner core layer is made of PP material. The thickness of the outer skin layer is 2mm. The thickness of the inner core layer is 30mm.

[0033] A method for preparing a lightweight car panel, the steps are as follows:

[0034] S1. Take two flat molds, clean them, and then treat the clean two flat molds with a release material, then spray the gel coat evenly on the flat molds, and finally send the flat molds into the press for heating and curing. The heating and curing time of the flat mold is 35 minutes. Use masking paper to circle the area where the length and width of the pre...

Embodiment 3

[0040] Such as figure 1 As shown, a lightweight compartment panel includes a gel coat layer 1 , an outer skin layer 2 and an inner core layer 3 . The outer skin layer 2 is installed on both sides of the inner core layer 3 . The gel coat layer 1 is installed on both sides of the outer skin layer 2 . The outer skin layer 2 is made of fiberglass. The inner core layer 3 has a honeycomb structure. The inner core layer is made of PP material. The thickness of the outer skin layer is 3mm. The thickness of the inner core layer is 40mm.

[0041] A method for preparing a lightweight car panel, the steps are as follows:

[0042] S1. Take two flat molds, clean them, and then treat the clean two flat molds with a release material, then spray the gel coat evenly on the flat molds, and finally send the flat molds into the press for heating and curing. The heating and curing time of the flat mold is 40min. Use masking paper to circle the area where the length and width of the prefabri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com