Magnetic levitation cargo loading and unloading circulation system

A cargo handling and turnover system technology, applied in loading/unloading, transportation and packaging, conveyors, etc., can solve the problems of high cost and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

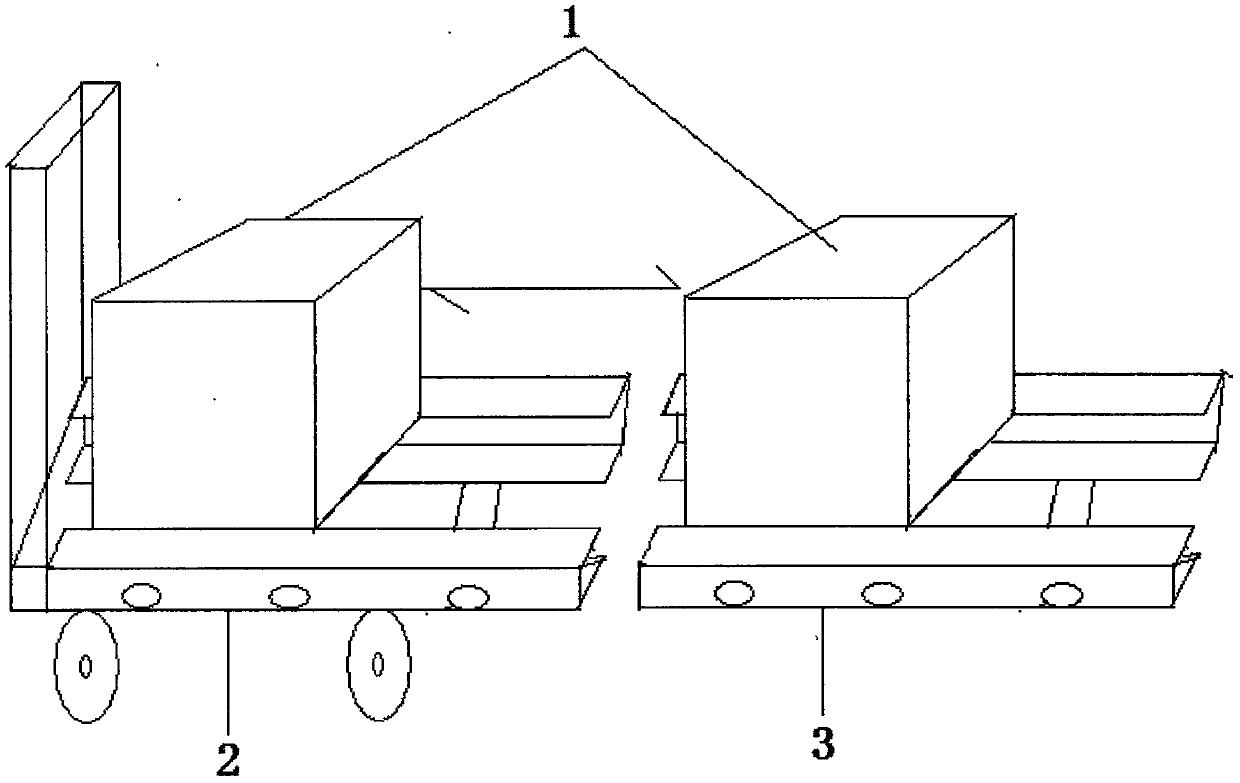

[0052] The working principle of the maglev cargo loading and unloading turnover system will be described below in conjunction with the accompanying drawings.

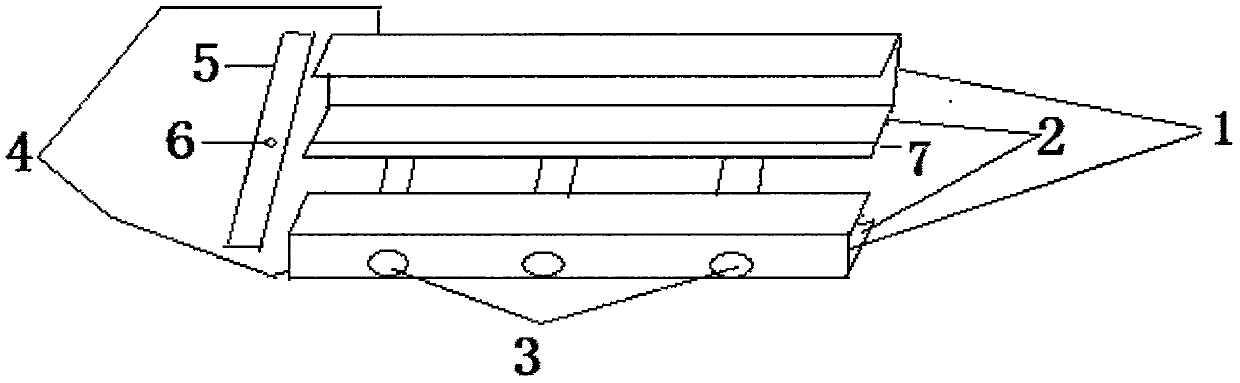

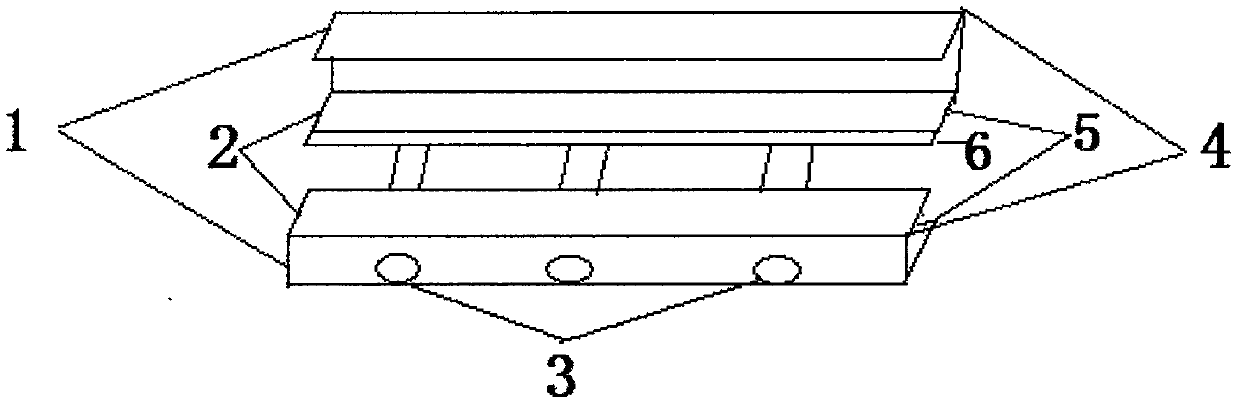

[0053] as attached figure 1 As shown, before the cargo loading and unloading operation, first through the displacement of the car, the magnetic levitation track body on the chassis of the car ( figure 1 The rear port of middle 2) and the magnetic levitation track body on the field ( figure 1 3) in the front port combination, while the spring-loaded connecting rod ( Figure 5 ) into the front end of the pin set piece ( Figure 6 ) into the snap ring mouth and hit the opening lock piece ( Figure 6 5), so that the card pin ( Figure 6 Middle 4) and opening bolt ( Figure 6 Middle 3) is popped up, and the card ( Figure 6 2) Insert the card slot ( Figure 5 Middle 2), so that the pinning piece ( Figure 6 ) to lock the spring-loaded connecting rod ( Figure 5 ), so that the magnetic levitation track body on the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com