Polycarbodiimide-containing polyurethane dispersion and preparation method thereof

A technology of polycarbodiimide and polyurethane dispersions, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor hydrolysis resistance, and achieve the effects of preventing hydrolysis, excellent crosslinking ability, and excellent reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

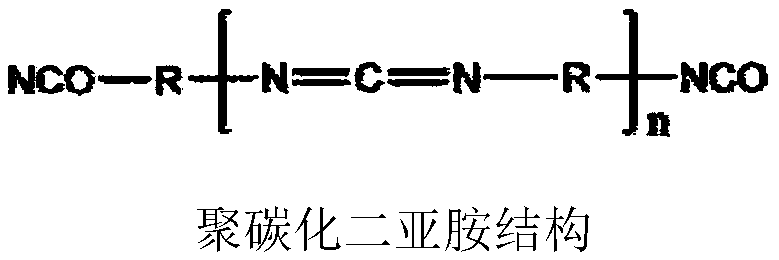

[0032] Embodiment 1 (preparation of polycarbodiimide)

[0033] In a 250ml four-necked flask equipped with a stirrer, a thermometer, an air duct (through nitrogen), and a vacuum adapter (connected to a vacuum pump), first purse with nitrogen and remove the air with a vacuum pump, and add 48.8g (0.2 mol) tetramethylxylylene diisocyanate (TMXDI) and 0.5g catalyst 1-methylphosphole-1-oxide (MPPO), heated to 180 ° C while stirring, and real-time monitoring in the reaction device Changes in isocyanate content, until the NCO content reached 8.2wt%, stop heating. At this moment, the vacuum pump was opened, and the remaining unreacted TMXDI and catalyst (MPPO) were evaporated under reduced pressure. According to the above synthesis method, isocyanate-terminated polycarbodiimide (PCDI) with a degree of polymerization of 4 was prepared.

Embodiment 2

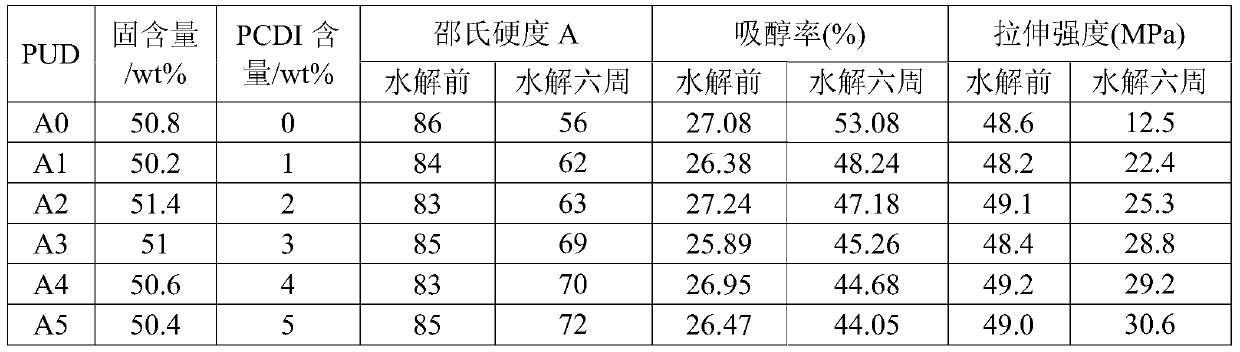

[0034] Embodiment 2 (preparation not containing polycarbodiimide polyurethane dispersion)

[0035] Add 86.68g of polybutylene adipate diol 2000 (PBA2000) into a 500ml three-neck round bottom flask equipped with a condenser, a stirrer and a thermometer, and remove water under vacuum at 120°C and 0.01MPa for 1 hour. When the temperature was lowered to 60°C, 7.58g of hexamethylene diisocyanate (HDI) and 2.5g of isophorone diisocyanate (IPDI), 0.02g of dibutyltin dilaurate (DBTDL) were added as a catalyst, and the temperature was raised to 80°C for 1.5 h. Titrate the remaining amount of -NCO with the di-n-butylamine method until the -NCO content reaches 1.13 wt%. Cool down to 60°C, add 150g of acetone to dissolve. Add 2.2 g of sodium ethylenediaminoethanesulfonate (AAS-Na) and react at room temperature for 20 minutes. Then slowly add 100 g of deionized water at 800 r / min and stir for 20 min to obtain a milky white dispersion. After stirring for 30 min, 1.02 g of isophorone dia...

Embodiment 3

[0036] Embodiment 3 (preparation containing polycarbodiimide polyurethane dispersion)

[0037] Add 86.68g of polybutylene adipate diol 2000 (PBA2000) into a 500ml three-neck round bottom flask equipped with a condenser, a stirrer and a thermometer, and remove water under vacuum at 110°C and 0.01MPa for 2h. When the temperature was lowered to 60°C, 7.58g of hexamethylene diisocyanate (HDI) and 2.28g of isophorone diisocyanate (IPDI), 0.02g of dibutyltin dilaurate (DBTDL) were added as a catalyst, and 1.04g of polymerization degree was added at the same time. 4 TMXDI type polycarbodiimide (PCDI), and then heated up to 90°C, and reacted for 1.5h. Titrate the remaining amount of -NCO with the di-n-butylamine method until the -NCO content reaches 1.12wt%. Cool down to 50°C, add 150g of acetone to dissolve. Add 2.2 g of sodium ethylenediaminoethanesulfonate (AAS-Na) and react at room temperature for 20 minutes. Then slowly add 100 g of deionized water at 800 r / min and stir for 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com