Tetrapropyl fluoro elastomer composition capable of resisting high-temperature water environment and preparation method of tetrapropyl fluoro elastomer composition

A tetrapropylene fluoride rubber and water environment technology, applied in the field of rubber materials, can solve the problems of low elongation, decreased sealing performance, low temperature resistance of rubber materials, etc., and achieve the effects of improving sealing performance, reducing quantity, and reducing swelling degree

Active Publication Date: 2019-05-14

CHINA PETROLEUM & CHEM CORP +1

View PDF5 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

During the use process, due to the strong oxidation of high temperature water, the cross-linking bonds and molecular main chain of tetrapropylene fluorine rubber are broken, and its mechanical properties are reduced.

At the same time, the molecular chain is broken to form carboxyl group, which is a hydrophilic group, which makes water penetrate into the rubber matrix, increases the quality and volume of tetrapropylene fluoride rubber, and reduces the sealing performance.

[0004] The Chinese patent with the publication number CN101168656A (the application number is CN200710031581.5) discloses a fluorine rubber seal and its preparation method, and the Chinese patent with the publication number CN104356563A (the application number is CN201410658075.9) discloses a high temperature and high pressure resistant Fluorine rubber compound with water vapor; but the disclosed rubber material has low temperature resistance (<200°C), and the preparation process is relatively complicated

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~6

[0032] Embodiments 1-6 high-temperature stabilizers use different types of oxides or hydroxides

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

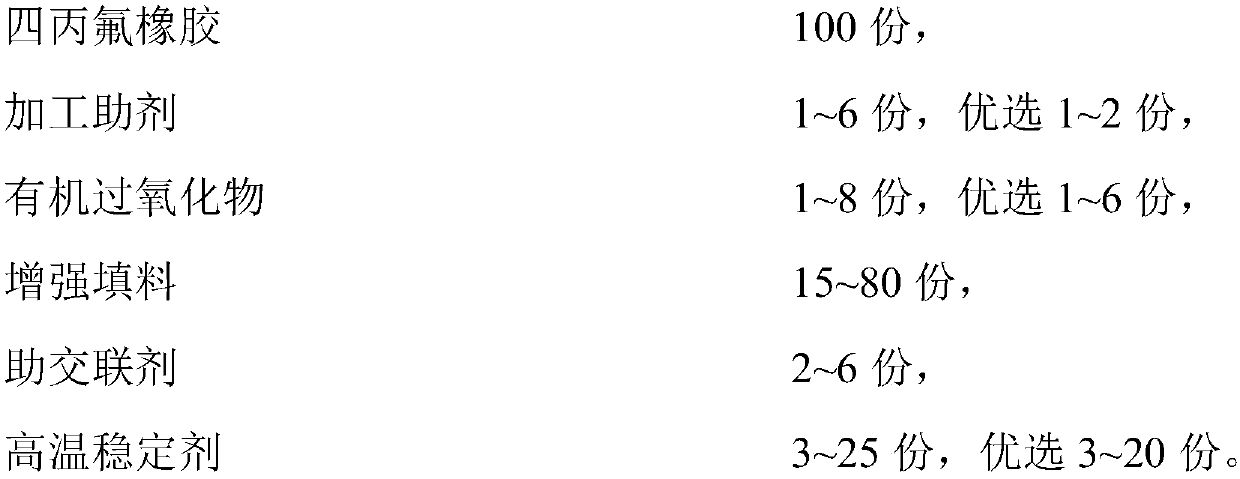

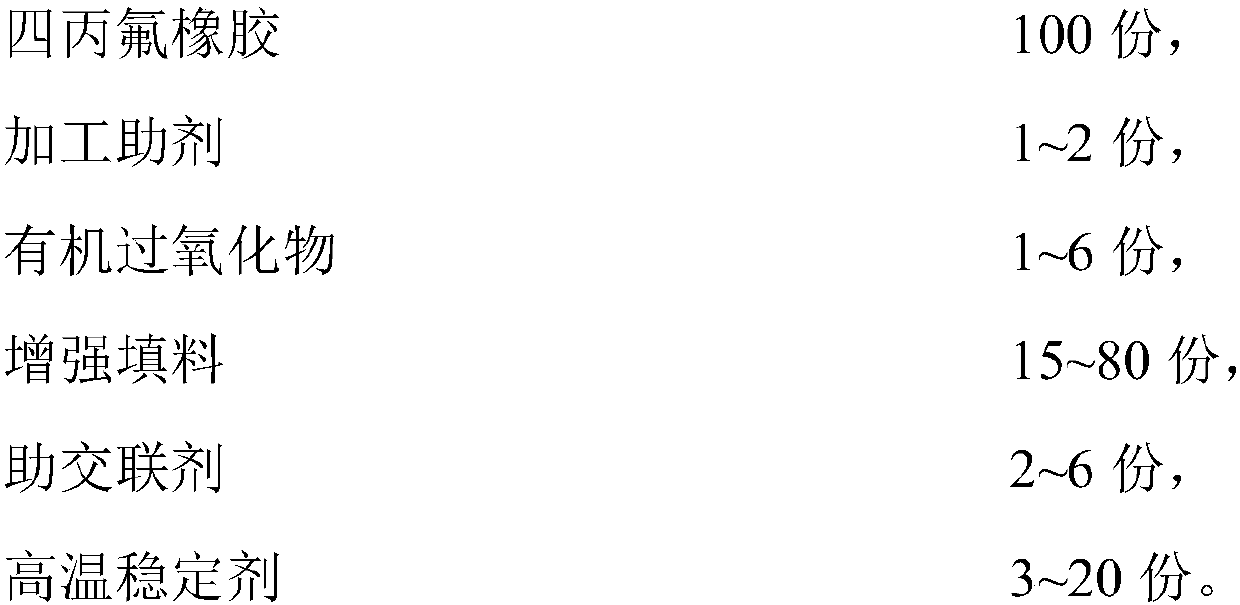

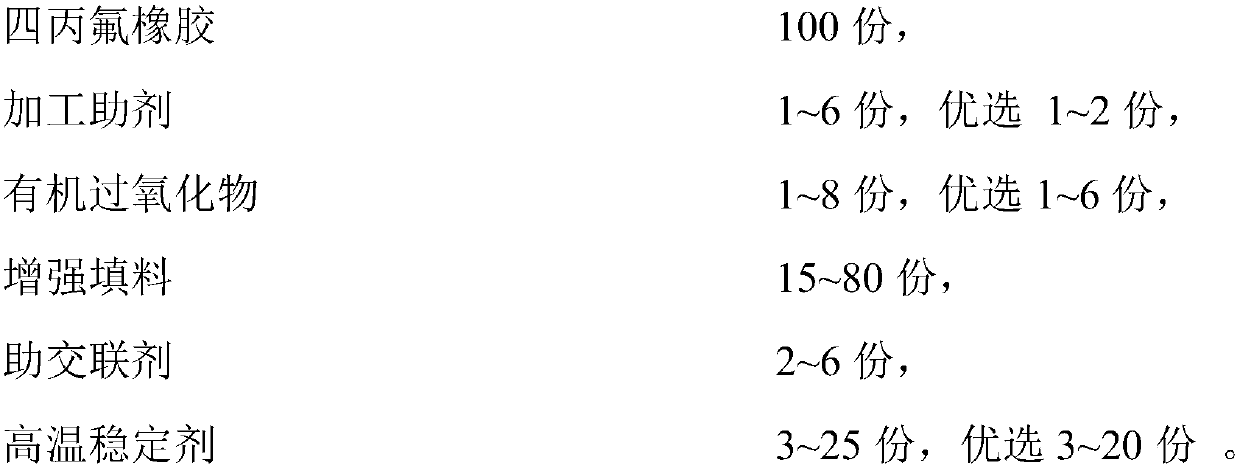

The invention relates to a high-temperature water environment resistant tetrapropyl fluoro elastomer composition and a preparation method thereof, and belongs to the field of rubber materials. The high-temperature water environment resistant tetrapropyl fluoro elastomer composition comprises the following components in parts by weight: 100 parts of tetrapropyl fluoro elastomer, 1-6 parts of a processing aid, 1-8 parts of organic peroxide, 15-80 parts of a reinforcing filler, 2-6 parts of an auxiliary crosslinking agent and 3-25 parts of a high-temperature stabilizer. After the tetrapropyl fluoro elastomer composition materail is aged for 24 hours in a high-temperature water environment at the temperature of 350 DEG C, the hardness, the tensile strength and the elongation retention rate ofthe tetrapropyl fluoro elastomer composition material are obviously higher than those of rubber without a high-temperature stabilizer, and the volume retention rate is close to 90%. The tetrapropyl fluoro elastomer material resisting corrosion of the high-temperature water environment can be used as a main material of a rubber barrel of a thermal recovery packer, so that the thermal recovery packer with better performance is formed and applied to heavy oil recovery at home and abroad, and the high-temperature water environment resistant tetrapropyl fluoro elastomer composition has wide application prospect.

Description

technical field [0001] The invention relates to the field of rubber materials, in particular to a high-temperature water-resistant tetrapropylene fluorine rubber composition and a preparation method thereof. Background technique [0002] At present, steam injection is mostly used in the production of heavy oil, and the thermal recovery packer is the main tool and equipment. The temperature resistance of the packer directly affects the reliability and life of the packer. Most of the existing thermal recovery packer rubber barrels use high temperature resistant materials such as polytetrafluoroethylene. [0003] Tetrapropylene fluorine rubber is a polar rubber with a wide range of uses, and can be used in high-temperature thermal recovery steam flooding environments containing oil and water. Due to the strong oxidation of high-temperature water during use, the cross-linking bonds and molecular main chains of tetrapropylene fluororubber are broken, resulting in a decrease in i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L27/18C08K13/02C08K3/04C08K5/098C08K3/22C08K5/14

Inventor 张瑞阮臣良马兰荣李夯李富平冯丽莹

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com