Method for making cool sense denim from multifunctional sheath-core fibers

A manufacturing method and skin-core technology, applied in textiles and papermaking, yarn, textile and other directions, can solve the problems of low heat dissipation, heavy weight, poor heat resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

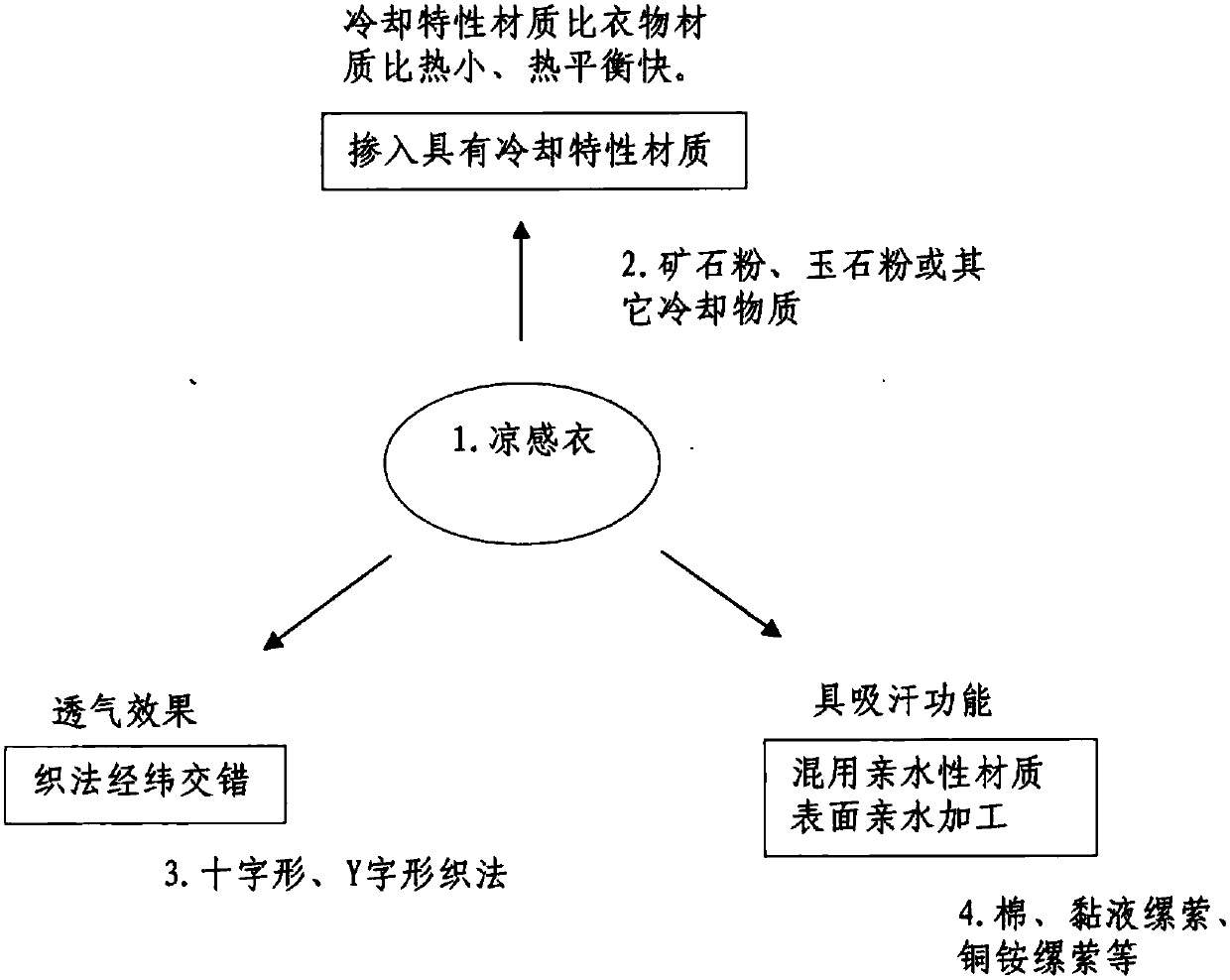

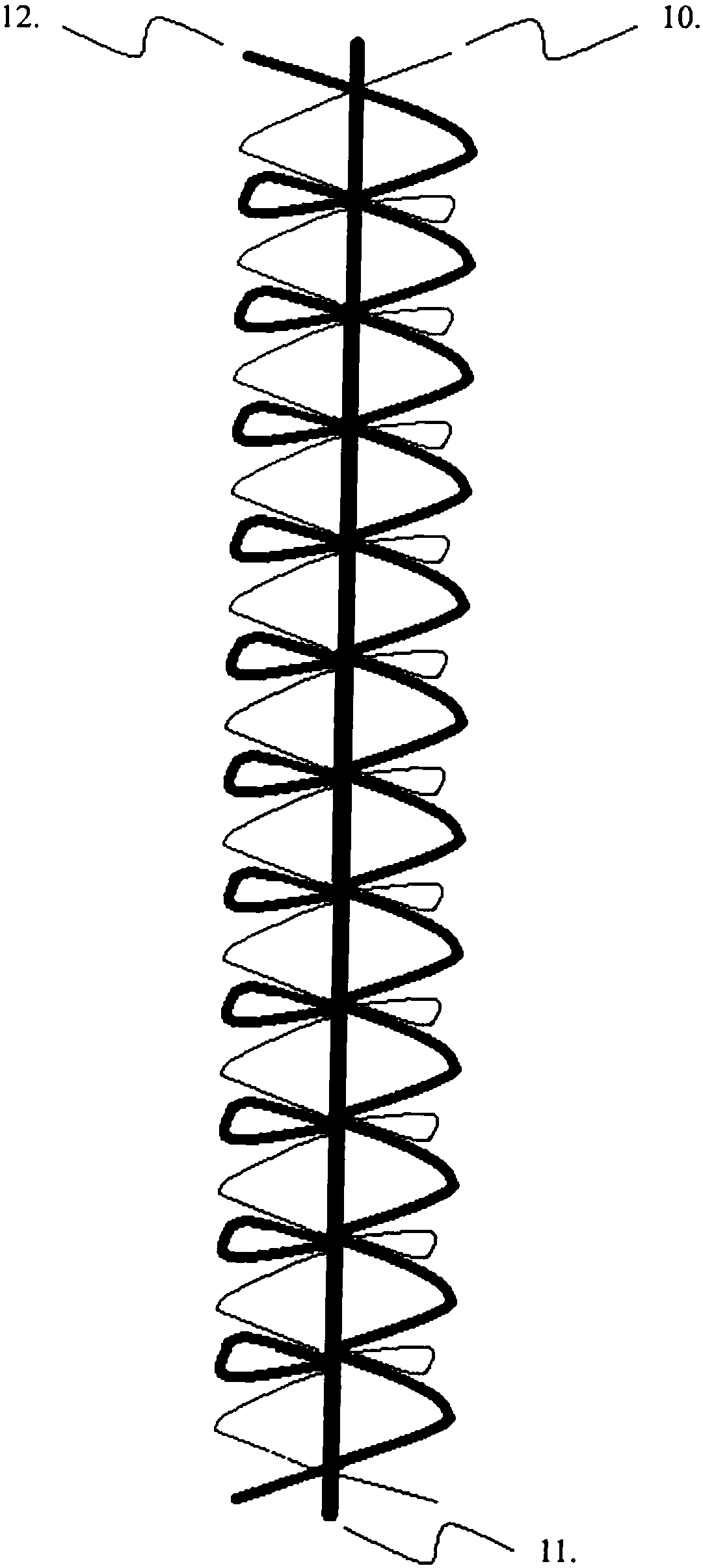

[0065] Please refer to figure 1 , explaining the principle of the existing cooling clothing 1, there are three types, the first type is the material with cooling properties, the material with cooling properties has a smaller specific heat than the material of the clothing, and the heat balance is faster. For example, ore powder, jade powder or other cooling substances 2; the second type is the breathable effect of interlaced warp and weft weaving, such as cross-shaped, Y-shaped weave 3; the third type is mixed with hydrophilic materials or surface hydrophilic processing, such as Cotton, mucus rayon, copper ammonium rayon, etc. with sweat-absorbing effect 4.

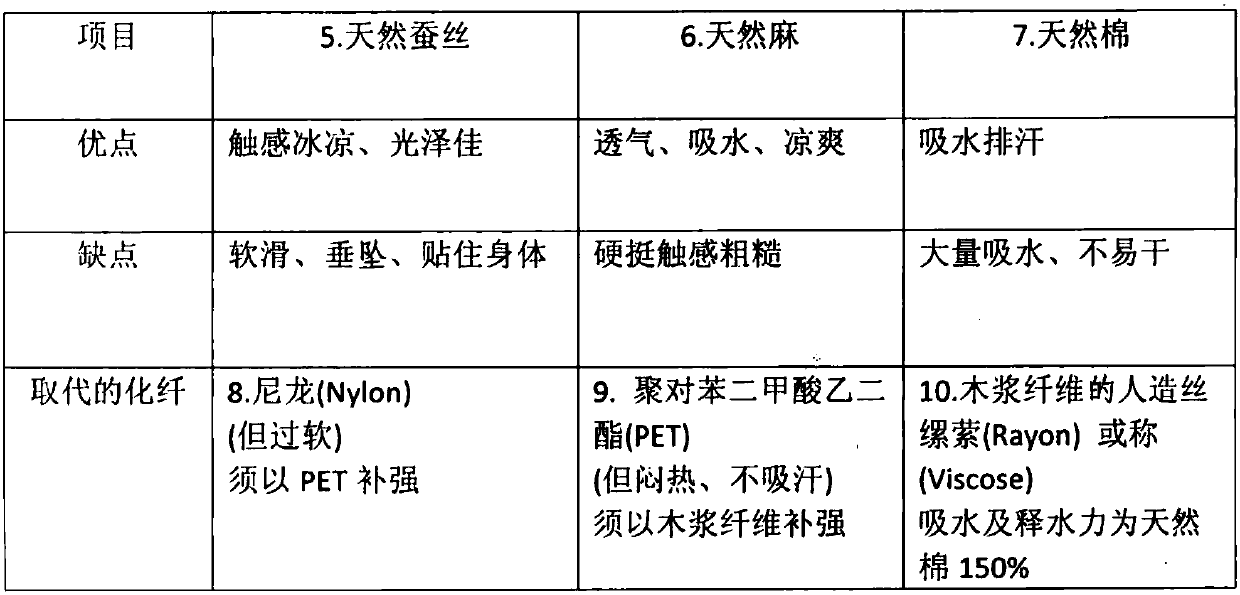

[0066] Please refer to figure 2 Explain how the new generation of synthetic fibers can replace natural hemp6, natural cotton7 and natural silk5. Natural silk 5 has the advantages of cool touch and good luster, but it also has the disadvantages of being soft, slippery, drape, and sticking to the body. It can be replaced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com