Rotating spoiler breakwater and its wave-proof floating unit

A floating body and spoiler technology, applied in the directions of breakwaters, embankments, jetties, etc., can solve the problems of insignificant wave elimination effect of long-period waves, insufficient oxidation resistance and structural strength, and large flexibility, and achieve good wave protection. effect, ease of processing, and the effect of improving the wave absorbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

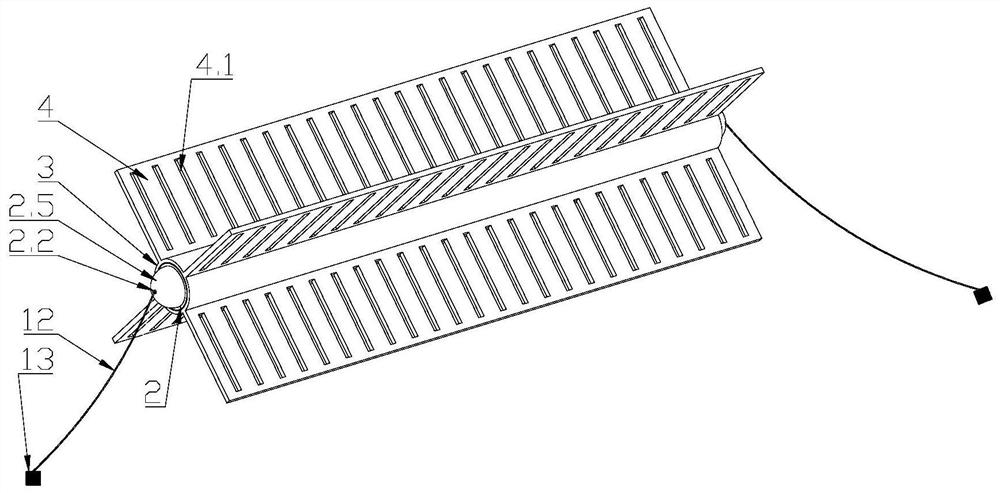

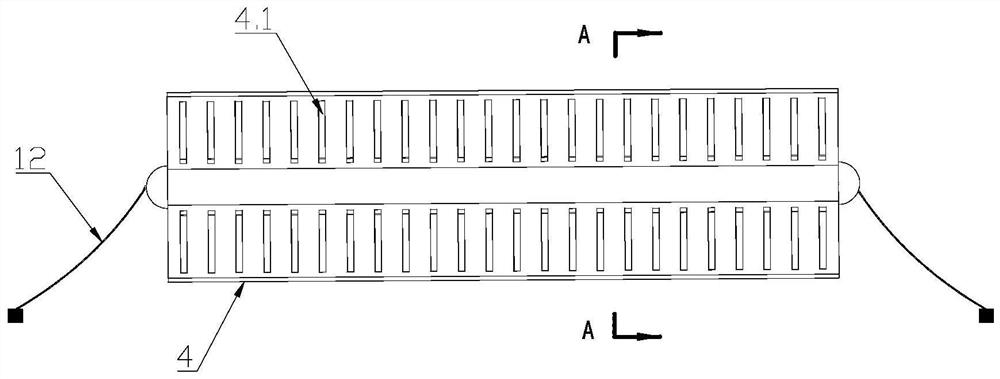

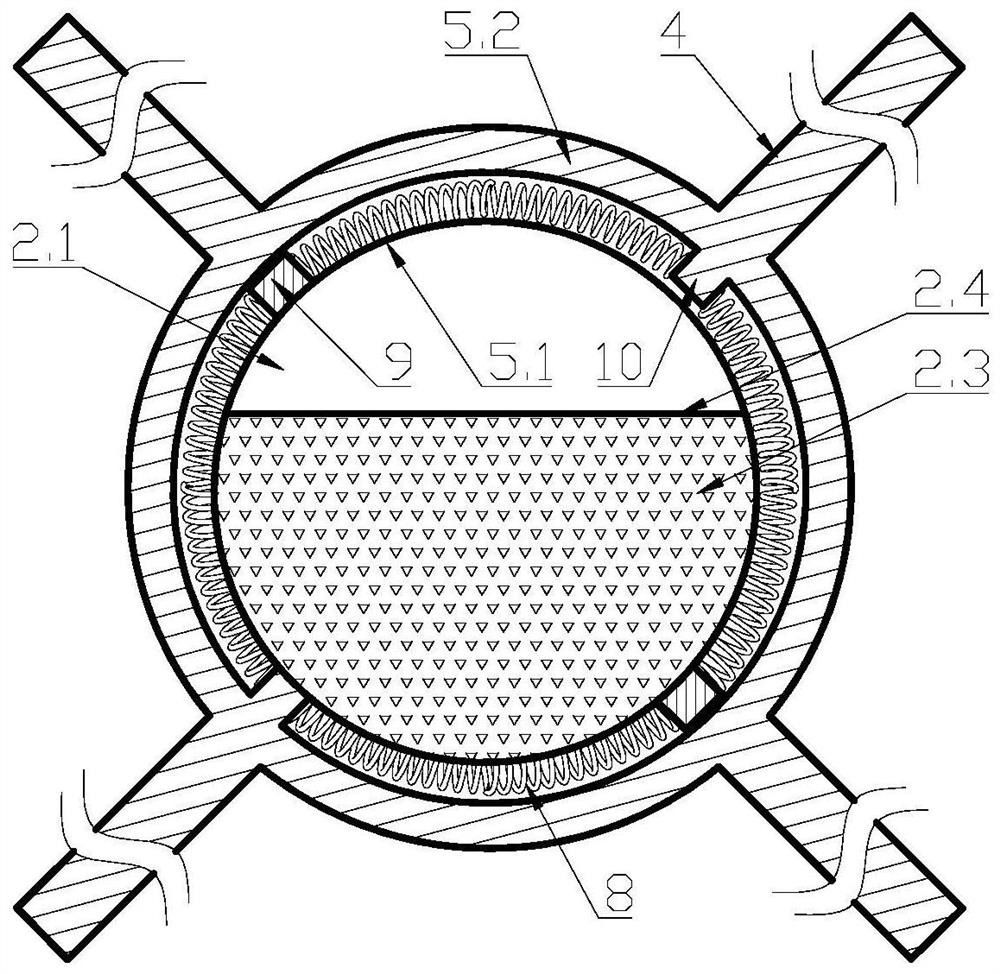

[0032] Such as Figure 1~4 , Figure 6 As shown, the anti-wave floating body unit 1 designed in this embodiment includes an inner cylinder 2 and an outer cylinder 3 . in:

[0033] The inner cylinder 2 adopts a watertight steel cylinder, and a cavity partition plate 2.4 is arranged inside it. Cavity dividing plate 2.4 is parallel to the axial direction of inner cylinder 2, and the inner cavity of inner cylinder 2 is divided into two independent and respectively airtight parts of buoyancy aid cavity 2.1 and density chamber 2.3. The function of the buoyancy aid cavity 2.1 is to provide buoyancy for the main body of the breakwater to ensure that the structure of the breakwater is stable at the specified waterline. The function of the density chamber 2.3 is to lower the center of gravity of the breakwater. The density chamber 2.3 is completely filled with water, and there is no sloshing problem of the free liquid surface , this design method is similar to the tumbler principle, ...

Embodiment 2

[0039] Such as Figure 5 As shown, the basic structure of the rotary turbulent breakwater designed in this embodiment is the same as that of Embodiment 1, the difference is that a spring bearing device 7 is used between the inner cylinder 2 and the outer cylinder 3 to replace the damping energy dissipation device 5 and bearing 6.

[0040] The spring bearing device 7 includes a third inner ring 7.1, a third outer ring 7.2, and four sets of springs 8 and four sets of rollers 11 surrounding the annular space between the two. As a simplified structure, the spring bearing device 7 uses the inner cylinder 2 as its third inner ring 7.1, and the outer cylinder 3 as its third outer ring 7.2. Each group of springs 8 includes a plurality of springs 8 arranged side by side along the circumference of the inner cylinder 2 and perpendicular to the axial direction of the inner cylinder 2, and each group of rollers 11 includes a plurality of rollers 11 arranged side by side along the axial di...

Embodiment 3

[0042] Such as Figure 7 As shown, the rotating spoiler breakwater designed in this embodiment includes a plurality of anti-wave floating body units 1 ( Figure 7 Two are used as an example, and more can be used in practice), and each anti-wave floating body unit 1 adopts the anti-wave floating body unit 1 in Embodiment 1 or 2. During actual construction work, each anti-wave floating body unit 1 forming the breakwater is towed from the wharf to a designated sea area, each anti-wave floating body unit 1 is independent of each other, connected with cables 12 and anchors 13, and anchored in front of the waves 13 can be fixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com