Secondary parallel heat pump unit

A technology of parallel connection of heat pump units, applied in the field of heat pumps, to achieve the effects of reducing irreversible heat transfer losses, reducing transmission and distribution energy consumption and pipeline network investment, and improving comprehensive energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

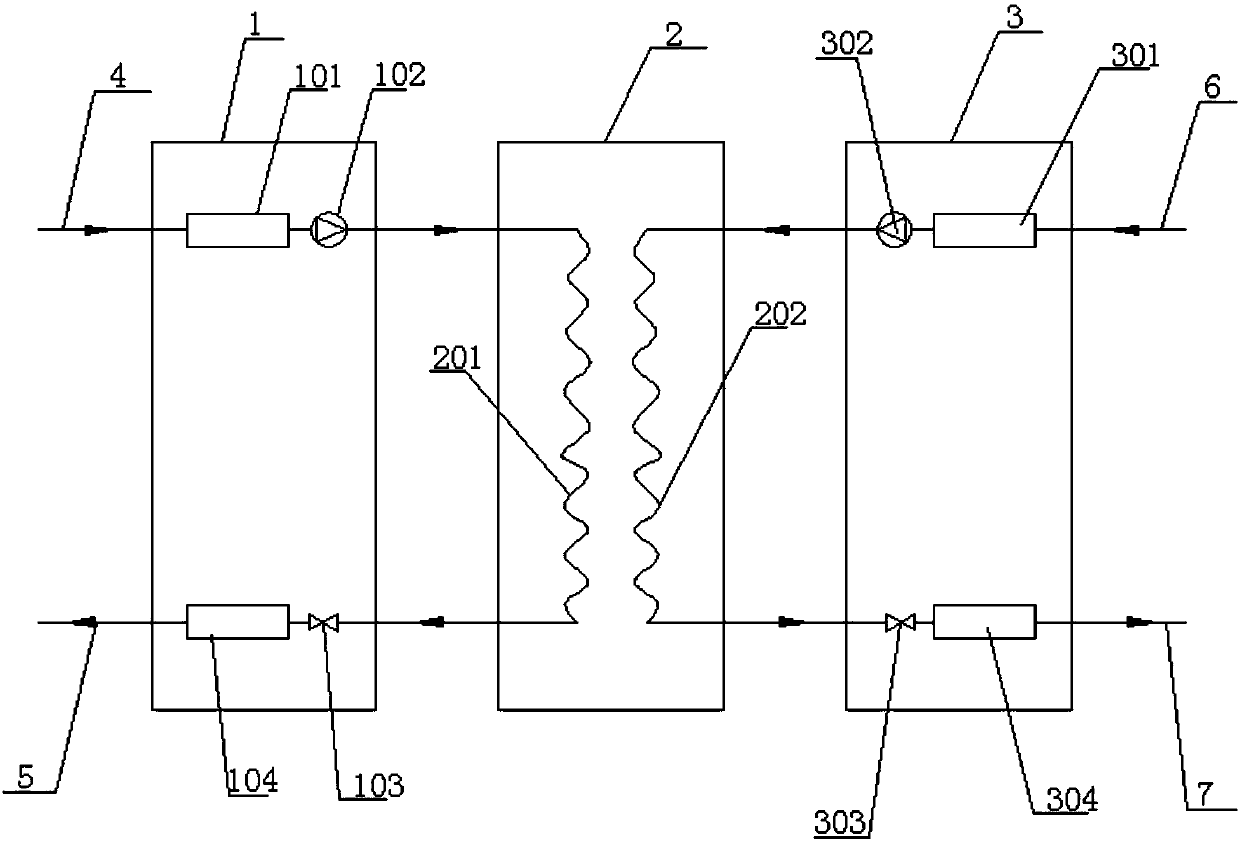

[0023] Such as figure 1 The two-stage parallel heat pump unit includes two first heat pump units 1 and second heat pump units 3 arranged in parallel, and a heat exchange is arranged between the first heat pump unit 1 and the second heat pump unit 3 Unit 2; the first heat pump unit 1 is mainly used to heat cold water, the second heat pump unit 2 is mainly used to cool down the hot water entering the second heat pump unit 2, and the heat exchange unit 2 Mainly to exchange heat between the hot water heated in the first heat pump unit and the cooled water in the second heat pump unit, which can realize gradient heating and cooling, reduce the temperature difference between the evaporator and condenser, and reduce the irreversible heat transfer loss , the overall coefficient of performance of the unit is improved.

[0024] The first heat pump unit 1 includes a first evaporator 101, a first compressor 102, a first solenoid valve 103 and a first condenser 104, and the cold water inl...

Embodiment 2

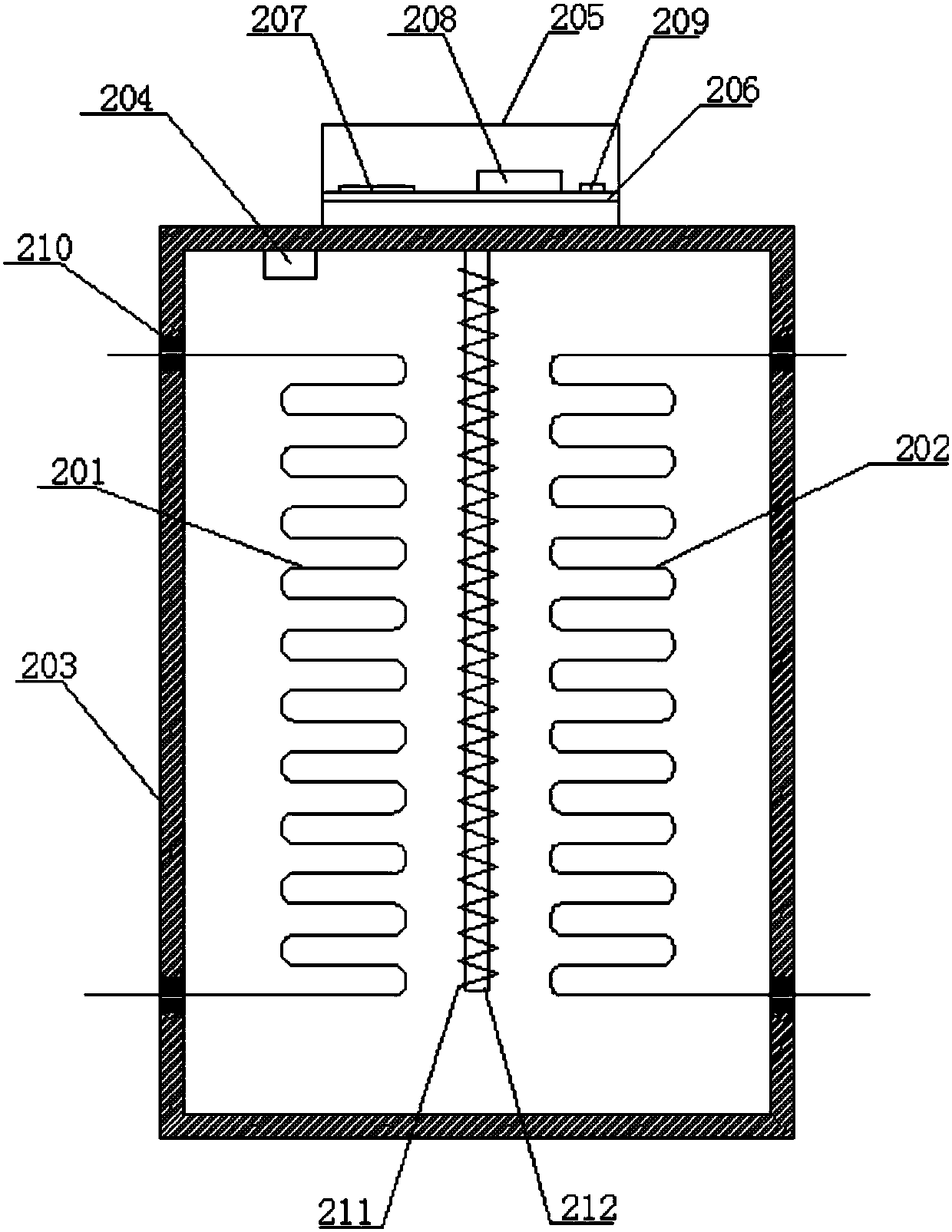

[0028] On the basis of Example 1, such as figure 2 The shown heat exchange unit 2 includes an insulated box body 203, the first heat exchange assembly 201 and the second heat exchange assembly 202 are arranged in the insulated box body 203, and the insulated box body 203 is provided with The temperature sensor 204 is electrically connected to the first solenoid valve 103 and the second solenoid valve 303 respectively. The temperature sensor 204 is used to detect the temperature in the heat preservation box 203, and control the degree of opening and closing of the first solenoid valve and the second solenoid valve through the detected temperature, for example, when the temperature is too high, control the first solenoid valve When the flow rate decreases, the flow rate of the second electromagnetic valve is controlled to increase. When the temperature is too low, the flow rate of the first electromagnetic valve is controlled to increase, and the flow rate of the second electro...

Embodiment 3

[0035] On the basis of Example 1, the first heat exchange component 201 and the second heat exchange unit 202 are both made of aluminum fins, and the finned first heat exchanger made of aluminum The thermal assembly 201 and the second heat exchange assembly 202 are arranged to cross each other. The first heat exchanging component 201 and the second heat exchanging component 202 are made of aluminum, which has higher heat exchanging performance. Fins are used for heat exchanging, which increases the heat exchanging area, and the cross setting can quickly conduct heat exchanging .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com