Sedimentation basin for mud-water separation and secondary sedimentation basin system

A mud-water separation and sedimentation tank technology, applied in water/sludge/sewage treatment, settling tank, biological water/sewage treatment, etc., can solve the problem of insufficient aeration of sludge at the bottom of the tank, short flow, and floating mud and other problems, to achieve the effect of reducing floating phenomenon, low water distribution requirements and high mud discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

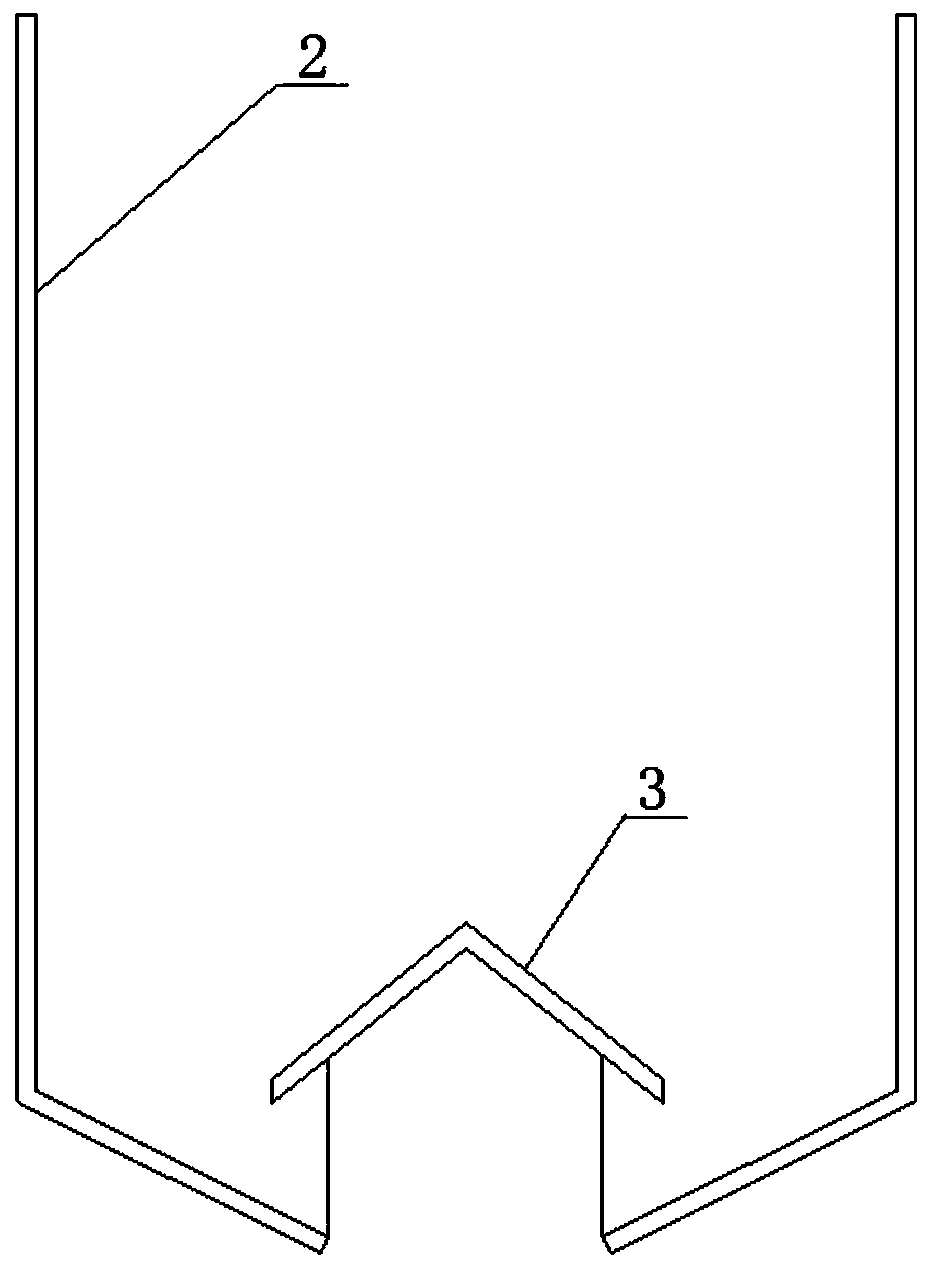

[0031] Embodiment 1, a sedimentation tank for mud-water separation, comprising a tank body 2, the tank body 2 includes an upper sedimentation area and a lower mud area, the lower mud area is arranged in a funnel shape, and the bottom of the tank body 2 is provided with a mud falling port , an air baffle 3 is fixed below the mud falling opening, and the vertical projection of the mud falling opening completely falls on the air baffle 3 . The area of the mud falling port accounts for 5% of the cross-sectional area of the upper sedimentation zone.

Embodiment 2

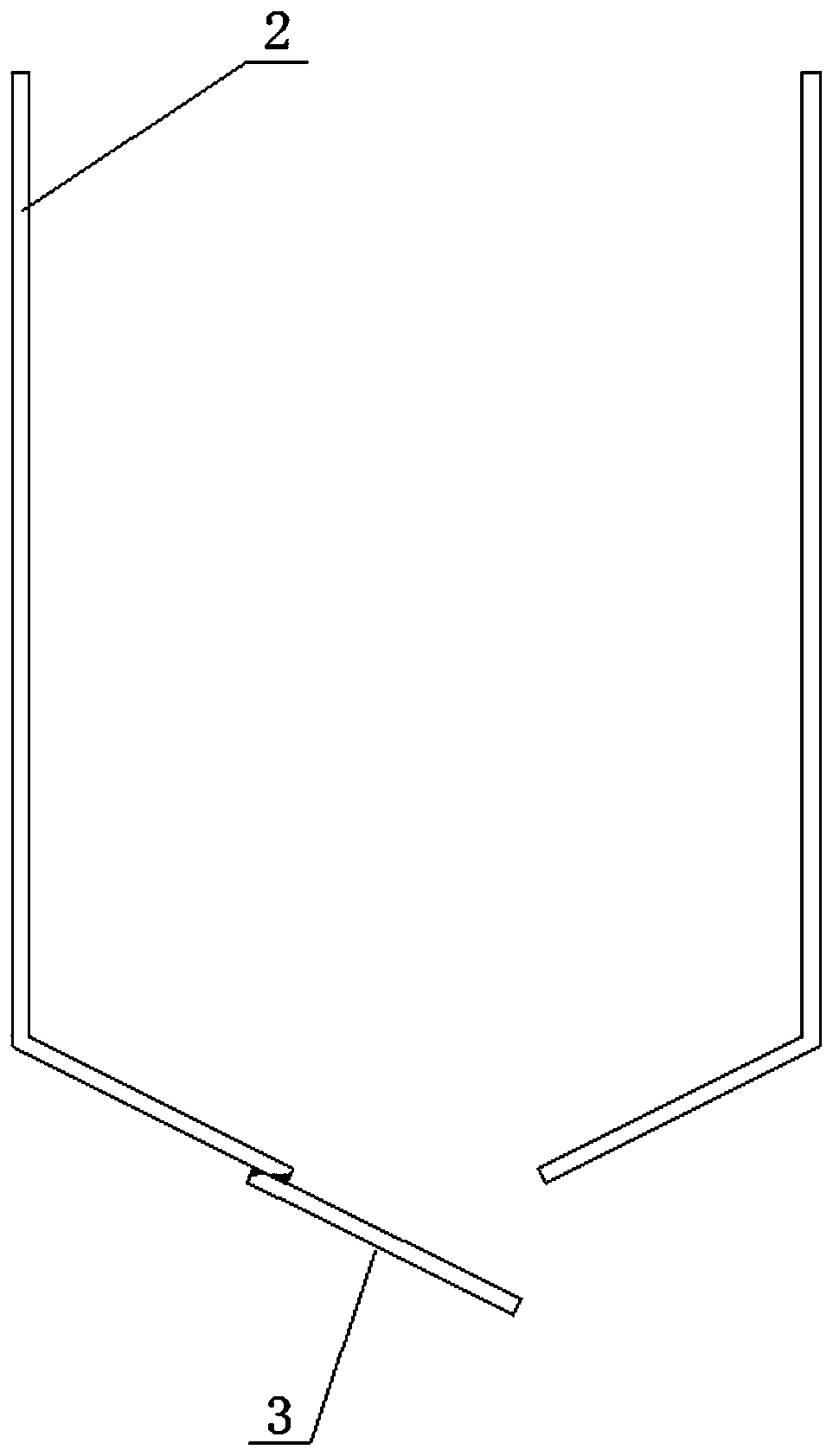

[0032] Example 2, in the sedimentation tank for mud-water separation described in Example 1: the area of the mud falling port accounts for 10% of the cross-sectional area of the upper sedimentation zone. refer to figure 1 The air baffle 3 is a flat plate, one end of the flat plate is fixedly connected to the pool wall of the pool body 2 on the side of the mudfall opening, and the other end is inclined downward.

Embodiment 3

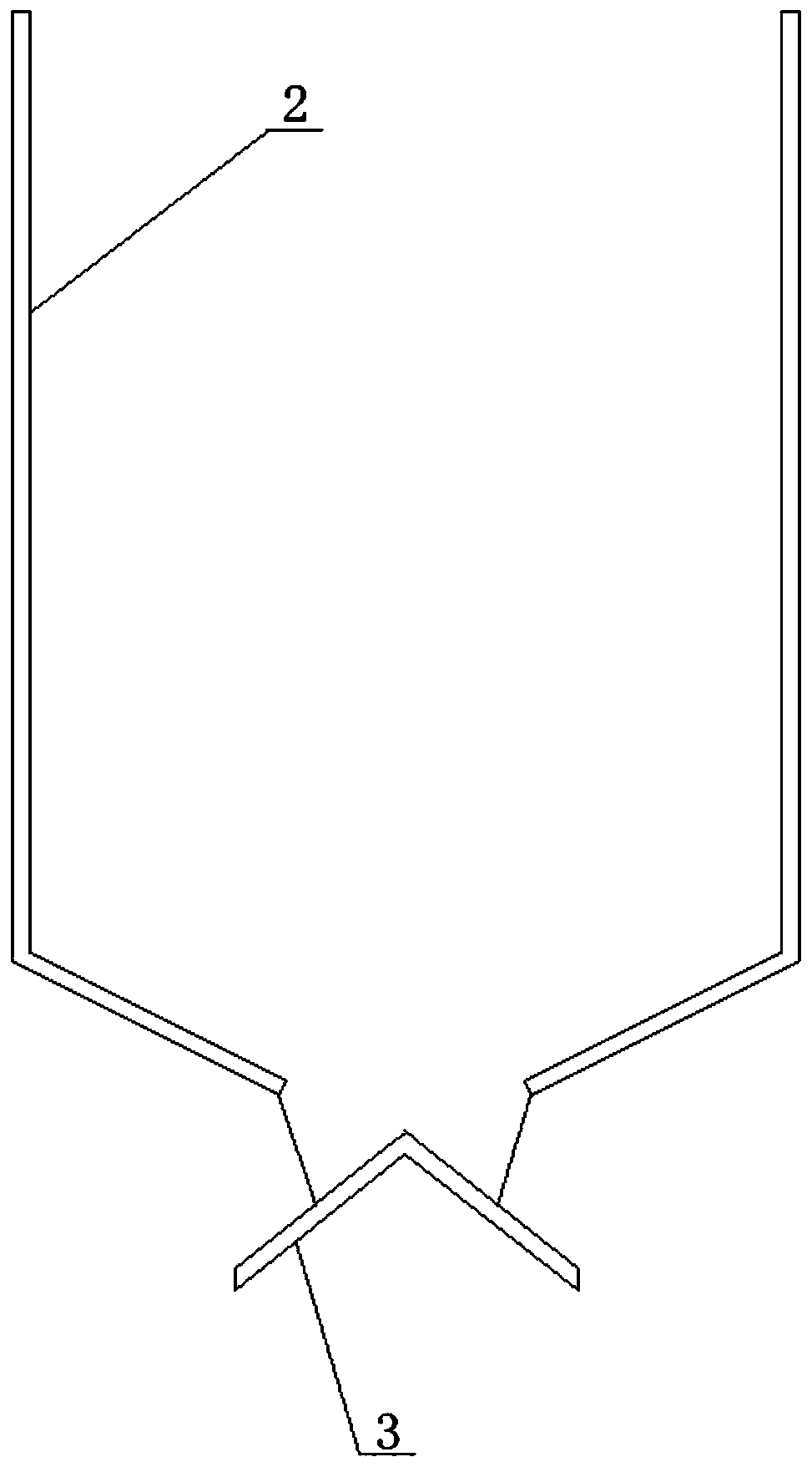

[0033] Example 3, in the sedimentation tank for mud-water separation described in Example 1 or 2: the area of the mud falling port accounts for 15% of the cross-sectional area of the upper sedimentation zone. refer to figure 2 , the air baffle 3 includes two flat plates, one end of the two flat plates is fixedly connected to form a certain angle to form a folded plate, the folded plate is fixedly installed under the mud falling opening through a bracket, and the top angle of the folding plate is set against the mud falling opening , to make the sludge slide down along the folded plate to avoid sludge accumulation on the folded plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com