Casting production method of cast copper sculpture

A technology of casting production and sculpture, which is applied in the field of handicraft production and processing technology, can solve the problems of wax mold breaking and shrinkage, and achieve the effect of good hardness, guaranteed production quality, not easy to segregate and loose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The casting production method of the cast copper sculpture mainly comprises the following steps:

[0028] The first step is to design the drawings, design the drawings according to the overall concept of the sculpture, and cast the sculpture according to the drawings;

[0029] The second step is to make clay drafts and make models according to the design drawings;

[0030] The third step is to remake the mold. The remake of the mold is determined according to the complexity of the work. The simpler works can be remade with plaster, and the complicated ones will be remade with silica gel. The present invention uses silica gel molds; it is characterized in that: In the mold remanufacturing operation, gates, risers, main runners, branch runners, ingates, exhaust risers, hidden risers, slag collection bags, etc. are prepared before mold assembly;

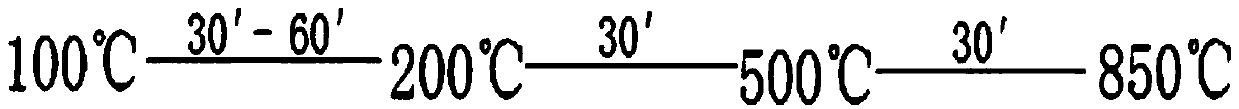

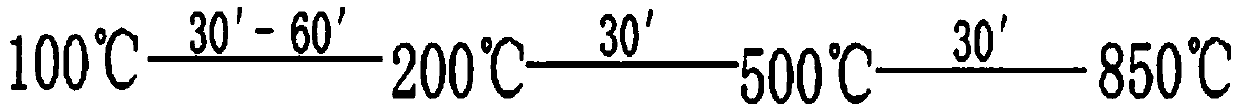

[0031] The fourth step is casting the wax pattern. After the mold is turned over, pour the melted paraffin into the mold that ...

Embodiment 2

[0037] The casting production method of the cast copper sculpture mainly comprises the following steps:

[0038] The first step is to design the drawings, design the drawings according to the overall concept of the sculpture, and cast the sculpture according to the drawings;

[0039] The second step is to make clay drafts and make models according to the design drawings;

[0040] The third step is to remake the mold. The remake of the mold is determined according to the complexity of the work. The simpler works can be remade with plaster, and the complicated ones will be remade with silica gel. The present invention uses silica gel molds; it is characterized in that: In the mold remanufacturing operation, gates, risers, main runners, branch runners, ingates, exhaust risers, hidden risers, slag collection bags, etc. are prepared before mold assembly;

[0041] The fourth step is casting the wax pattern. After the mold is turned over, pour the melted paraffin into the mold that ...

Embodiment 3

[0047] The casting production method of the cast copper sculpture mainly comprises the following steps:

[0048] The first step is to design the drawings, design the drawings according to the overall concept of the sculpture, and cast the sculpture according to the drawings;

[0049] The second step is to make clay drafts and make models according to the design drawings;

[0050] The third step is to remake the mold. The remake of the mold is determined according to the complexity of the work. The simpler works can be remade with plaster, and the complicated ones will be remade with silica gel. The present invention uses silica gel molds; it is characterized in that: In the mold remanufacturing operation, gates, risers, main runners, branch runners, ingates, exhaust risers, hidden risers, slag collection bags, etc. are prepared before mold assembly;

[0051] The fourth step is casting the wax pattern. After the mold is turned over, pour the melted paraffin into the mold that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com