Method for accelerating phase changing of bainite in steel through in-situ nanometer AlN heterogeneous nucleation

A bainite and nanotechnology, applied in the field of materials, can solve problems such as cost increase, manufacturing process complexity, and accelerated bainite transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A Fe-0.42C-1.5Si-1.8Mn-1.0Cr-0.3Mo-0.2Ni-0.1Al-0.01N steel, the rest is a small amount of impurities such as P and S, after the molten steel is smelted by an electric furnace, the molten steel is cast into a steel ingot , heat the steel ingot to 1200 °C for 5 hours, and then carry out the rolling thermal deformation of the steel ingot, the final deformation temperature is 900 °C, the deformation ratio is 8, and the deformation is divided into 8 times. AlN particles with a fraction of 0.1 vol.% uniformly distributed; heat the hot-formed billet to 950 °C, hold it for 2 h for austenitization, and then cool it to 350 °C at a cooling rate of 0.5 °C / s for 0.5 h. Air-cooled to room temperature; then heated to 350°C for 1 h and then air-cooled. The phase transformation time of the bainitic steel obtained by the above composition and treatment process is 0.5h, and the average thickness of the bainite lath is about 95nm.

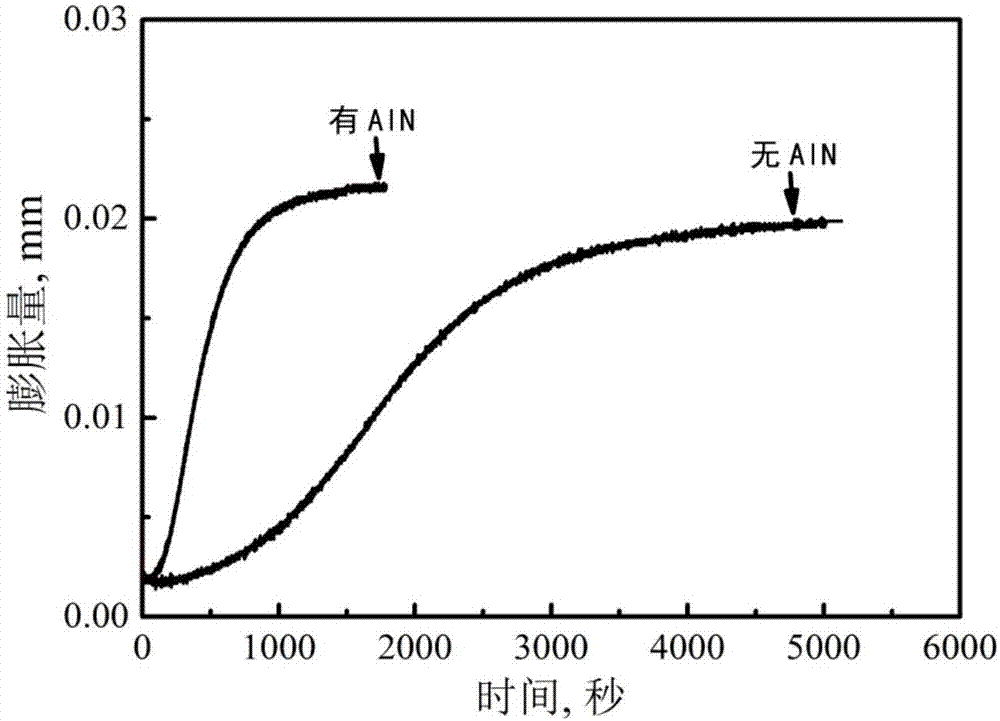

[0014] figure 1 As shown in the figure, the kinetic cur...

Embodiment 2

[0016] A Fe-0.70C-2.6Si-0.70Mn-0.41Cr-0.15Al-0.013N steel, the rest is a small amount of impurities such as P and S. After smelting molten steel with an electric furnace, the molten steel is cast into a steel ingot, and the steel ingot is heated to 1230 ℃ for 3 hours, and then the steel ingot is subjected to rolling hot deformation, the final deformation temperature is 920 ℃, the deformation ratio is 6, and the deformation is divided into 6 times. Evenly distributed AlN particles; heat the hot-formed billet to 900°C, hold it for 1 hour for austenitization, then cool it to 350°C at a cooling rate of 0.7°C / s for 1 hour, and then cool it to room temperature in air; then heat it to 320℃ for 2h and then air-cooled. The phase transformation time of the bainitic steel obtained by the above composition and treatment process is 1h, and the average thickness of the bainite lath is about 60nm.

Embodiment 3

[0018] A Fe-1.0C-2.0Si-0.21Mn-1.51Cr-0.20Al-0.020N steel, the rest is a small amount of impurities such as P and S, after the molten steel is smelted by an electric furnace, the molten steel is cast into a steel ingot, and the steel ingot is heated to 1250 After holding at ℃ for 2 hours, the steel ingot is subjected to rolling hot deformation, the final deformation temperature is 910 ℃, the deformation ratio is 6, and the deformation amount is divided into 5 times. Uniformly distributed AlN particles; heat the hot-formed billet to 860°C, hold it for 3 hours for austenitization, then cool it to 230°C at a cooling rate of 0.2°C / s for 4 hours, and then cool it to room temperature in air; then heat it to 250 °C for 2 hours and then air-cooled. The phase transformation time of the bainitic steel obtained by the above composition and treatment process is 4h, and the average thickness of the bainite lath is about 50nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com