A resistance spot welding method under the action of a controllable rotating magnetic field

A rotating magnetic field and resistance spot welding technology, applied in resistance welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of single magnetic field movement mode, poor mechanical properties of joints, non-rotatable magnetic field, etc. The effect of grain refinement and uniform heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

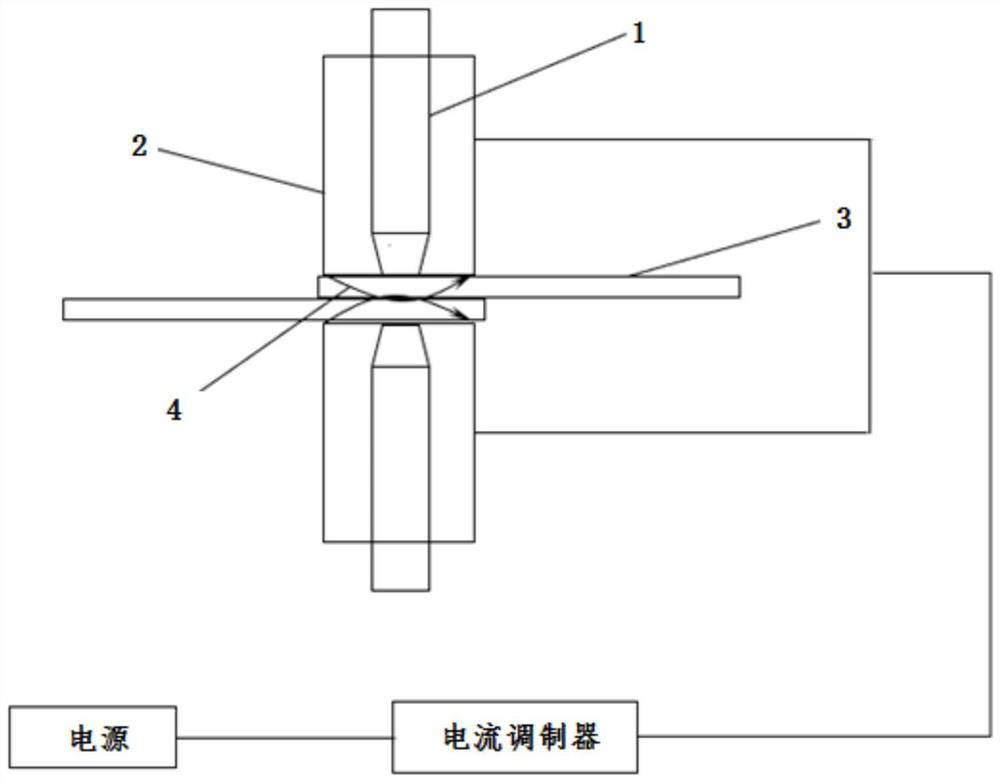

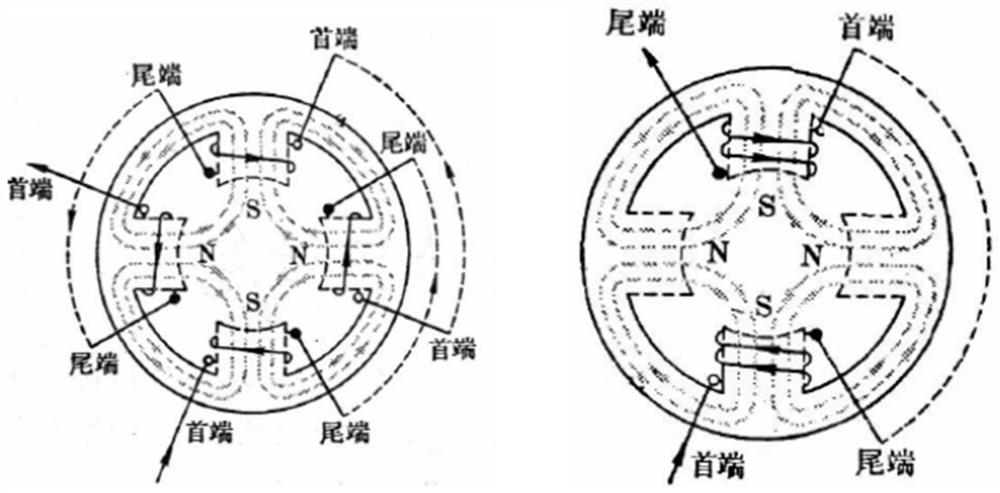

[0047] Example: Combined figure 1 and figure 2 , the resistance spot welding method under the action of a controllable rotating magnetic field of this embodiment is further elaborated:

[0048] First: For different welding conditions, use different welding fixtures to clamp and fix the workpiece to be welded. The fixture should ensure that the position of the welding spot can be positioned, and the welding current can flow through the welding workpiece from the end face of the electrode longitudinally during the welding process;

[0049] Second: adjust the welding parameters of the resistance welding machine, preset the welding current, welding time, and start the cooling water cycle;

[0050] Again: when the welding system is turned on, turn on the magnetic field generator, set the frequency, strength, and phase of the exciting three-phase alternating current, and check the distribution and movement of the magnetic field in the simulation mode;

[0051] Again: check the ai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com