Method for measuring and aligning during large shell horizontal assembly

A shell, large-scale technology, used in measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve problems such as low efficiency and poor accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

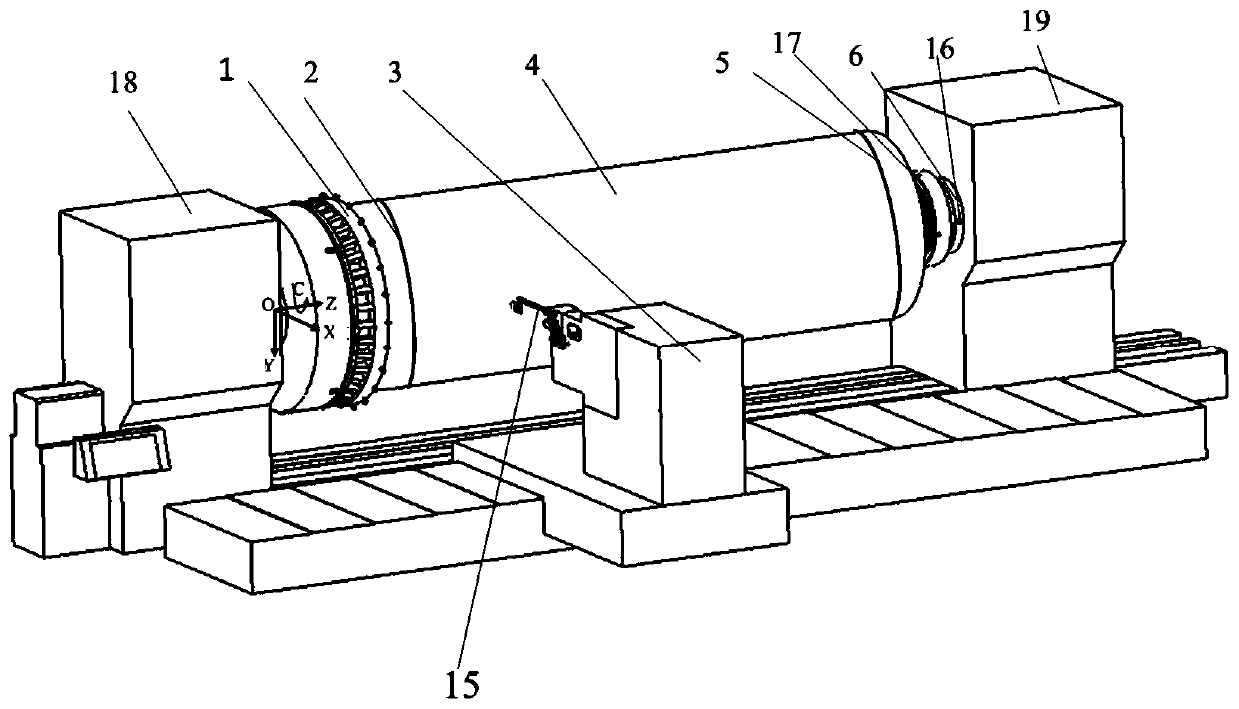

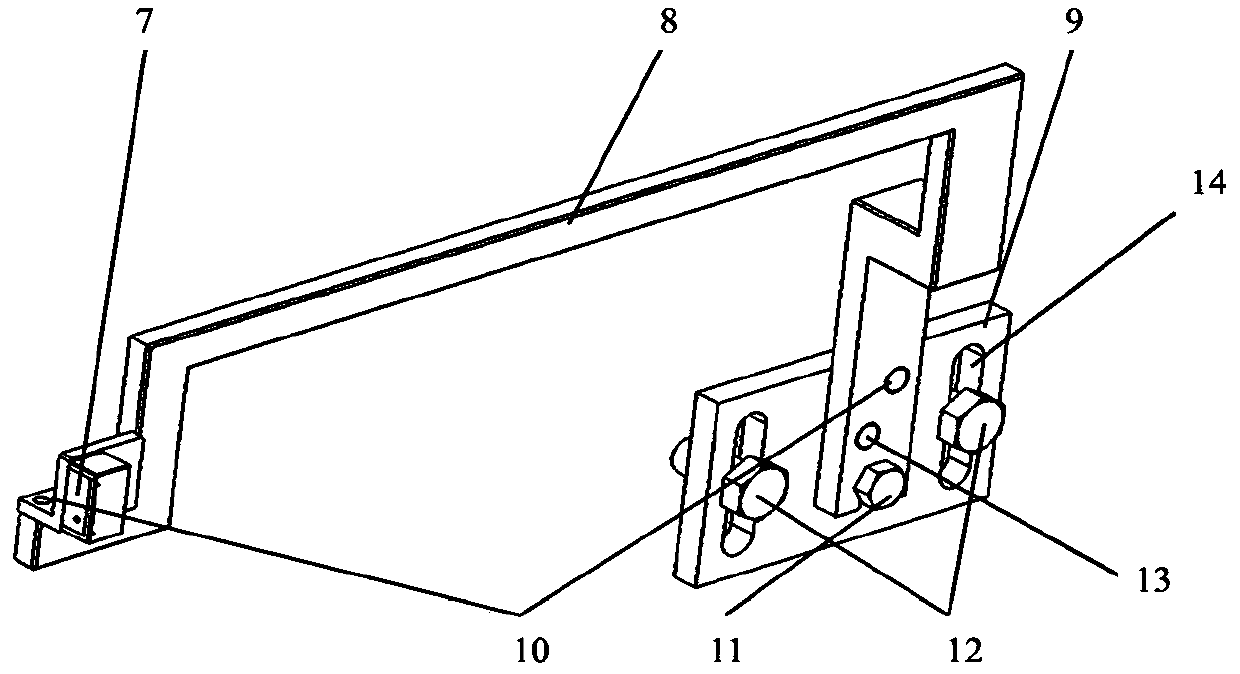

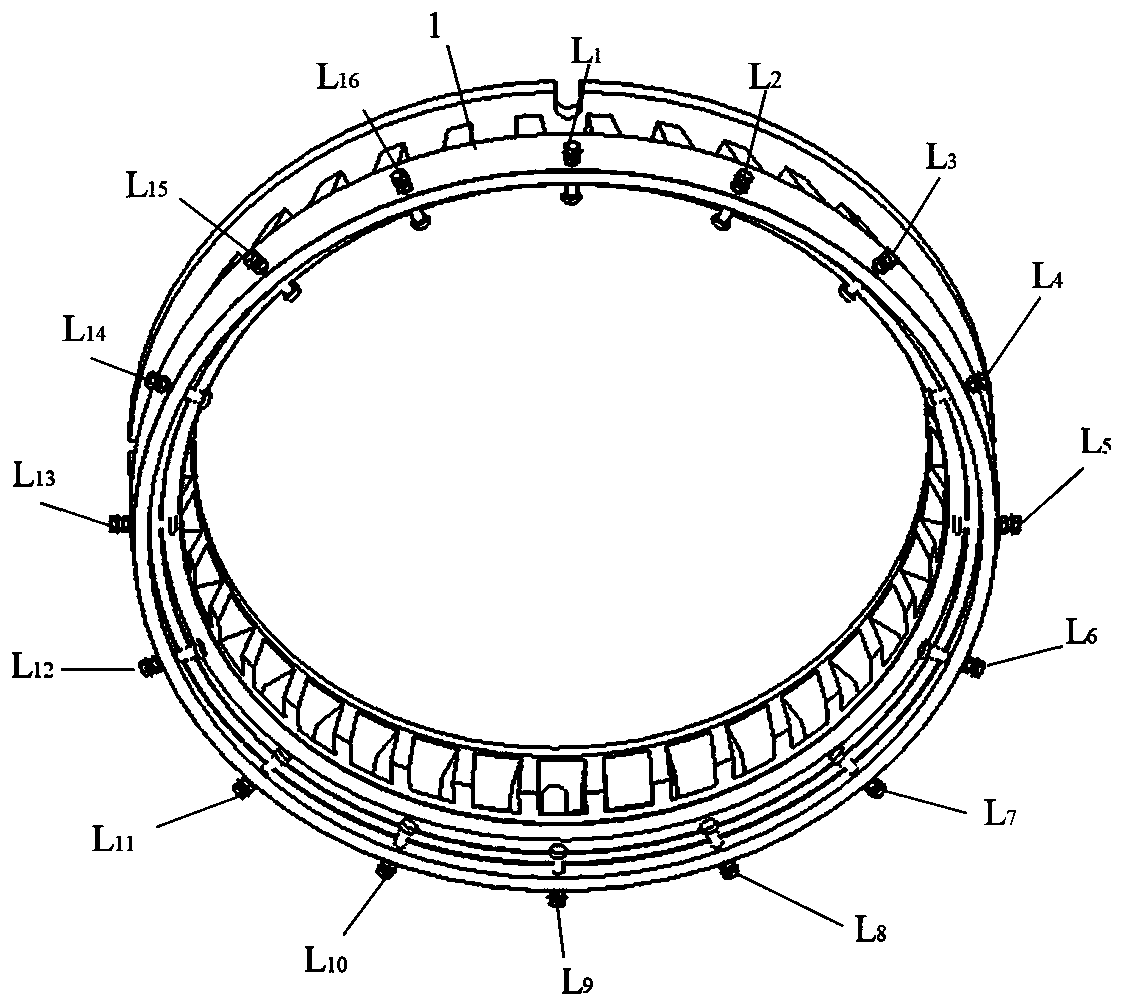

[0093] This embodiment is a measurement and alignment method for horizontal assembly of large housings. The large shell has a diameter of 1.8 m, a length of 6 m and a wall thickness of 5 mm. The front clamping surface of the large housing is close to one end of the machine tool head 18, and the front clamping surface is the outer circumferential surface at 50 mm from the front end of the housing; the rear clamping surface of the large housing is close to the machine tool tail box One end, and the rear clamping surface is the inner circumferential surface at a distance of 50 mm from the rear end surface of the housing. The measurement benchmarks are the reference circular line 2 at the front end of the shell and the reference circular line 5 at the rear end. Such as Figure 5 As shown, the front end reference circular line 2 is located on the outer circumferential surface of the housing, and the distance S1 between the front reference circular line and the front end surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com