Preparation method of sodium trimetaphosphate cross-linked hyaluronic acid gel and product of preparation method

A technology for cross-linking hyaluronic acid and sodium trimetaphosphate is applied in the preparation of sodium trimetaphosphate cross-linked hyaluronic acid gel and its product field, and can solve the problems of low yield, complicated gel preparation process and sticky feeling. It can achieve the effect of simple preparation process, lower production cost, and improved skin feel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

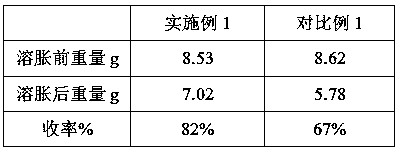

Embodiment 1

[0025] Dissolve 0.5 g of sodium hydroxide in 74 g of purified water, then add 6.0 g of sodium trimetaphosphate, dissolve under stirring, then add 20 g of hyaluronic acid (HA) (molecular weight: 1.48 million Daltons) under stirring, and disperse Evenly, place it in a water bath at 25°C to react for 4 hours. After the reaction is over, cut the gel into 0.1 cm small pieces, soak in 0.1 mol / L 900 mL hydrochloric acid solution, stir intermittently, swell until the volume remains constant, and wash with purified water 3 times, the dynamic viscosity is 2.25×10 5 mPa·s particle-free gel.

Embodiment 2

[0027] Dissolve 0.25 g of sodium hydroxide in 74 g of purified water, then add 6.0 g of sodium trimetaphosphate, dissolve under stirring, then add 20 g of HA (molecular weight is 700,000 Daltons) under stirring, disperse evenly, and place React in a water bath at 25°C for 18 h. After the reaction is over, cut the gel block into 0.1 cm small pieces, soak in 0.05 mol / L 900 mL hydrochloric acid solution, stir intermittently, swell until the volume remains constant, and wash 3 times with purified water , to obtain a dynamic viscosity of 1.50×10 5 mPa·s particle-free gel.

Embodiment 3

[0029] Dissolve 0.5 g sodium hydroxide in 74 g purified water, then add 3.0 g sodium trimetaphosphate, dissolve under stirring, then add 20 g HA (molecular weight is 1.77 million Daltons) under stirring, disperse evenly, place in React in a water bath at 25°C for 18 h. After the reaction is over, cut the gel block into 0.1 cm pieces, soak in 0.1 mol / L 900 mL hydrochloric acid solution, stir intermittently, swell until the volume remains constant, and wash twice with purified water , to obtain a dynamic viscosity of 2.34×10 5 mPa·s particle-free gel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com