Low fused ring content coal-based anthracene oil and low-temperature coal-based fuel oil containing low fused ring content coal-based anthracene oil

A technology for coal-based anthracene and fuel oil, which is applied in the fields of coal chemical industry and fuel science, can solve the problems of difficulty in transportation, loss of aromatic conjugated structure, loss of low-temperature crystallization properties, etc., and achieves the effect of low cost and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

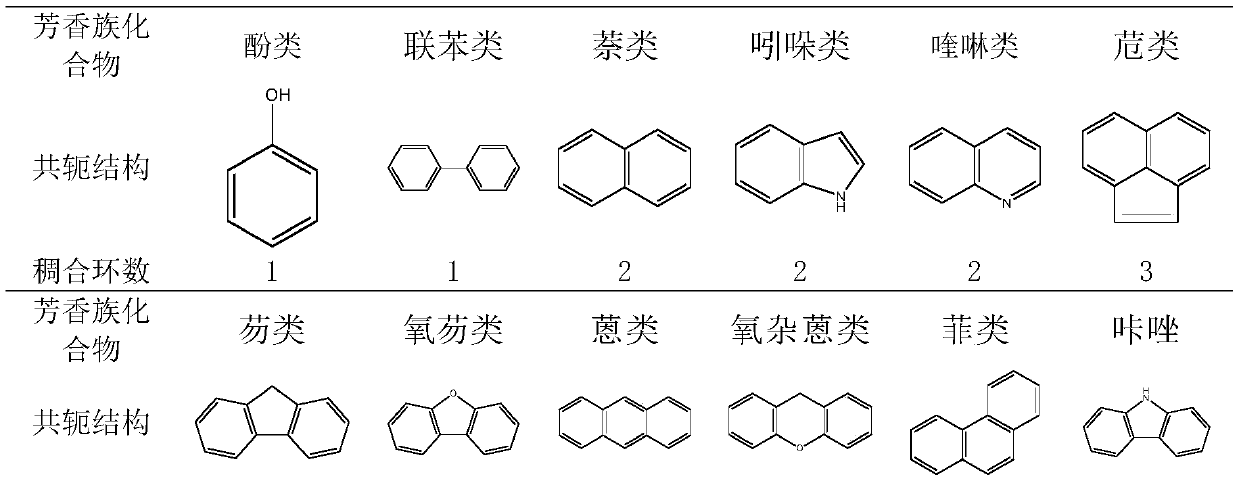

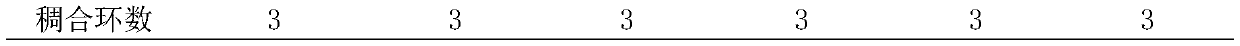

[0027] Coal-based anthracene oil, a fractionation component derived from coal tar, is added with graphene with a mass fraction of 0.02, cooled to 5°C for crystallization, and centrifuged to remove high-fused ring number components (ie, crystallized parts) to obtain low-fused ring number Anthracene oil, after analysis, the average number of fused rings in its aromatic conjugated structure is 1.8, and the yield is 85%. The anthracene oil with low fused ring number is used as fuel oil, which can withstand low temperature down to 3℃.

Embodiment 2

[0029] Coal-based anthracene oil, a fractionation component derived from coal tar, was added with graphene with a mass fraction of 0.5%, cooled to 15°C for crystallization, and centrifuged to remove high-condensed ring number components (ie, crystallized parts) to obtain low-fused rings The number of anthracene oil is analyzed, and the average number of fused rings in its aromatic conjugated structure is 1.2, and the yield is 88%. The anthracene oil with low fused ring number is used as fuel oil, which can withstand low temperature down to 4℃.

Embodiment 3

[0031] Coal-based anthracene oil, a fractionation component derived from coal tar, was added with graphene with a mass fraction of 1%, cooled to 40°C for crystallization, and centrifuged to remove the high-condensed ring number component (ie, the crystalline part) to obtain a low-fused ring The number of anthracene oil is analyzed, and the average number of fused rings in its aromatic conjugated structure is 1.7, and the yield is 95%. The anthracene oil with low fused ring number is used as fuel oil, which can withstand low temperature down to 9℃.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap