Bearing lubricating antirust oil and preparation method thereof

A bearing lubrication and anti-rust oil technology, applied in lubricating compositions, petroleum industry, etc., can solve the problems of low viscosity and poor anti-rust performance of anti-rust oil, achieve good anti-rust performance, excellent anti-rust performance, and improve bearing The effect of abnormal sound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

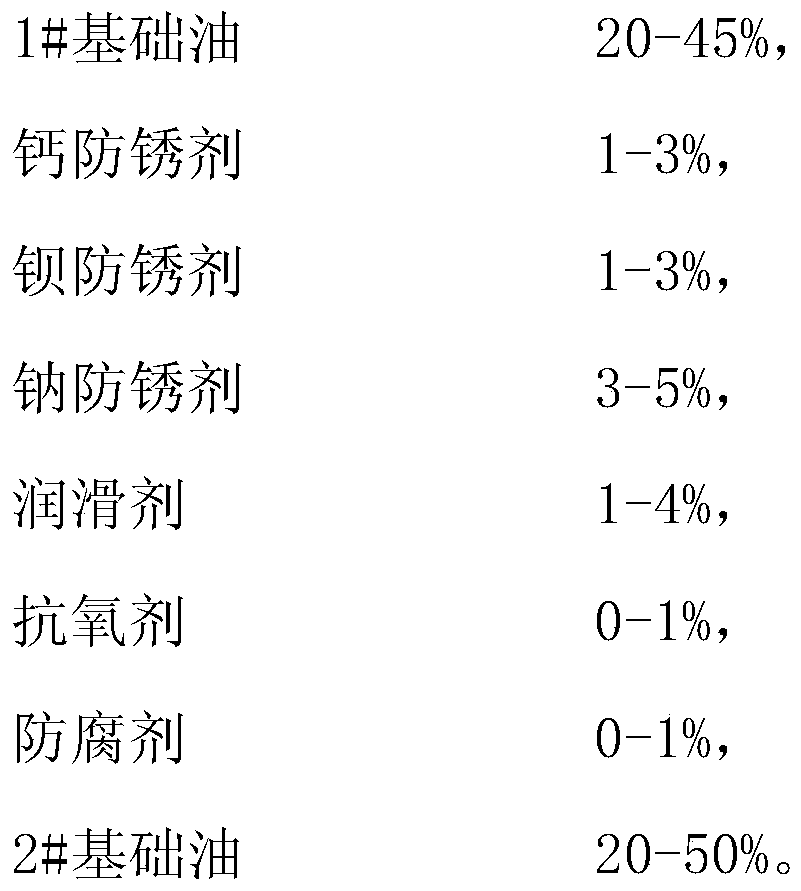

[0023] A bearing lubricating and antirust oil specifically includes the following components in mass percentage:

[0024]

[0025] The preparation method of the bearing lubricating antirust oil specifically comprises the following steps:

[0026] (1) Extract a certain quality of 150N base oil into the reactor by a metering pump;

[0027] (2) Start the stirring system, heat to 50±5°C, add calcium anti-rust agent, barium anti-rust agent, sodium anti-rust agent, lubricant, preservative, antioxidant in sequence, keep stirring and dissolve for 20 minutes to react and dissolve;

[0028] (3) Stop heating, continue to put 250N base oil into the reaction kettle, stir and dissolve for 20 minutes, and obtain bearing lubricating and antirust oil.

Embodiment 2

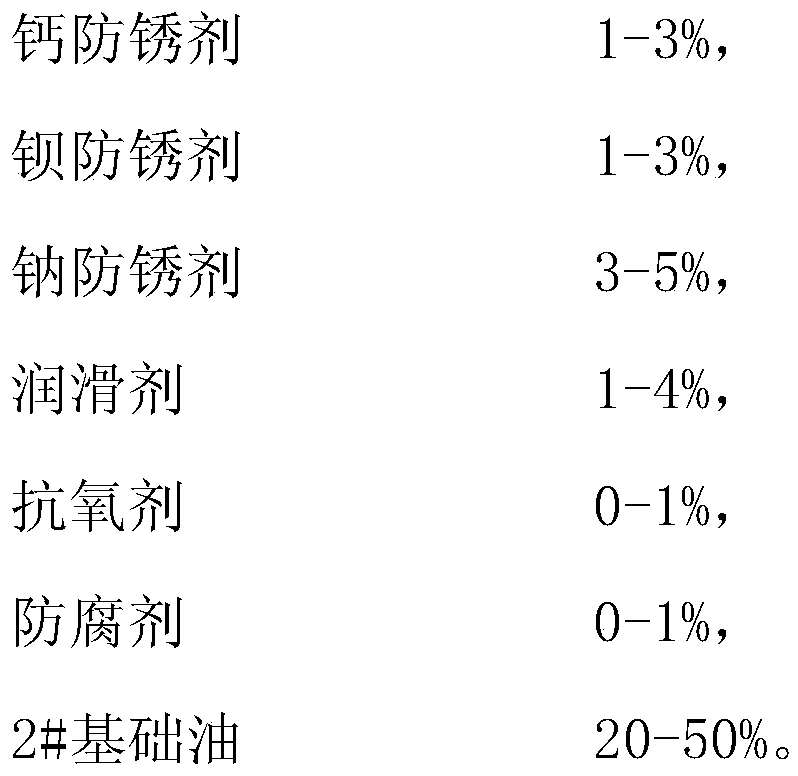

[0030] A bearing lubricating and antirust oil specifically includes the following components in mass percentage:

[0031]

[0032] The preparation method of the bearing lubricating antirust oil specifically comprises the following steps:

[0033] (1) Extract a certain quality of 150N base oil into the reactor by a metering pump;

[0034] (2) Start the stirring system, heat to 50±5°C, add calcium anti-rust agent, barium anti-rust agent, sodium anti-rust agent, lubricant, preservative, antioxidant in sequence, keep stirring and dissolve for 20 minutes to react and dissolve;

[0035] (3) Stop heating, continue to put 250N base oil into the reaction kettle, stir and dissolve for 20 minutes, and obtain bearing lubricating and antirust oil.

Embodiment 3

[0037] A bearing lubricating and antirust oil specifically includes the following components in mass percentage:

[0038]

[0039]

[0040] The preparation method of the bearing lubricating antirust oil specifically comprises the following steps:

[0041] (1) Extract a certain quality of 150N base oil into the reactor by a metering pump;

[0042] (2) Start the stirring system, heat to 50±5°C, add calcium anti-rust agent, barium anti-rust agent, sodium anti-rust agent, lubricant, preservative, antioxidant in sequence, keep stirring and dissolve for 20 minutes to react and dissolve;

[0043] (3) Stop heating, continue to put 250N base oil into the reaction kettle, stir and dissolve for 20 minutes, and obtain bearing lubricating and antirust oil.

[0044] The performance parameters of embodiment 3 gained antirust oil are as follows:

[0045] Check item

test result

testing method

Appearance (stock solution)

yellow transparent liquid

visual i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com