an alkaline degradation solution

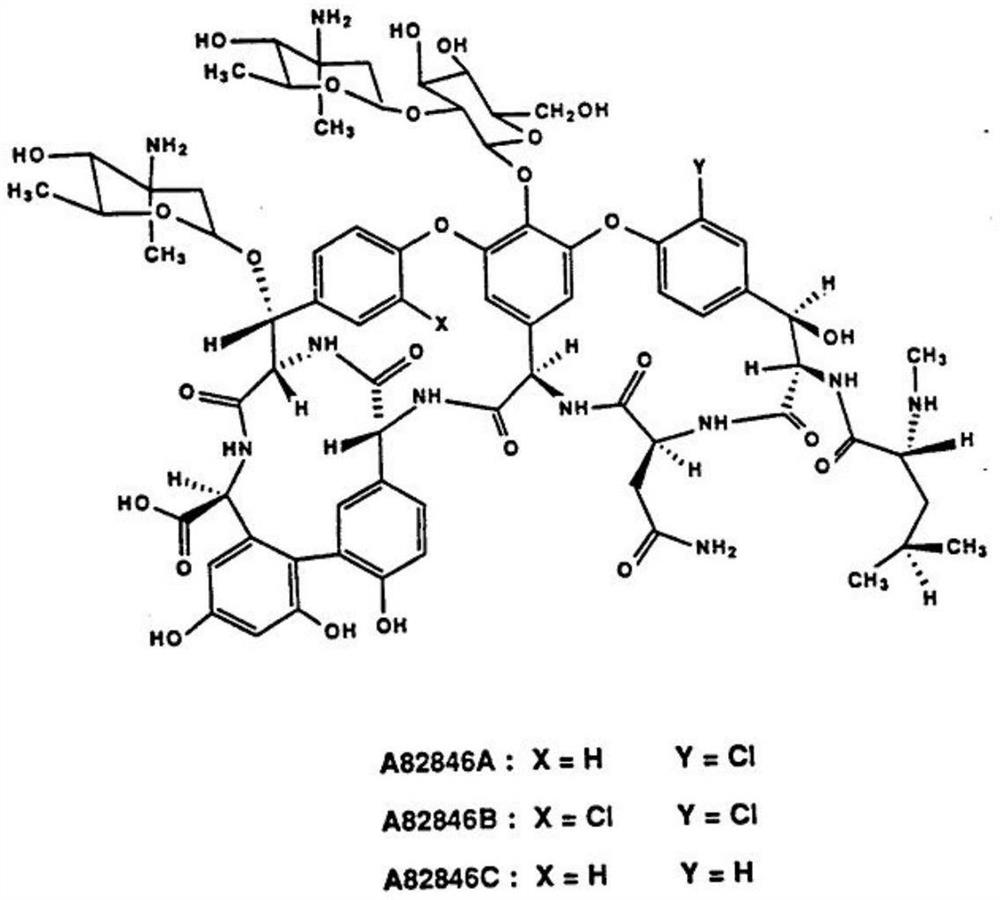

A degradation solution and alkali degradation technology, applied in the fields of peptides, biochemical equipment and methods, fermentation, etc., can solve the problems of affecting the extraction yield, low proportion of fermentation units and components, and increased production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation of embodiment 1 seed liquid

[0032] Seed medium: maltodextrin 20g / L, glucose 10g / L, soybean powder 15g / L, yeast extract 3g / L, calcium carbonate 1g / L, pH7.0.

[0033] Pack 150ml of seed culture medium into a 750ml Erlenmeyer bottle, and sterilize at 120°C for 30 minutes before use.

[0034] Inoculate the A82846B production strain Nocardia orientalis NRRL 18098 stored at low temperature into the prepared seed bottle, and shake the bottle for 40-50 hours at a temperature of 30°C and a rotation speed of 250 rpm to obtain mature shake bottle seeds.

Embodiment 2

[0036] Fermentation medium: maltodextrin 40g / L, molasses 20g / L, soybean powder 20g / L, yeast powder 10g / L, calcium carbonate 3g / L, calcium chloride 10g / L, pH7.0.

[0037] Pack 35L of fermentation medium in a 50L fermentation tank, and sterilize at 120°C for 30 minutes before use.

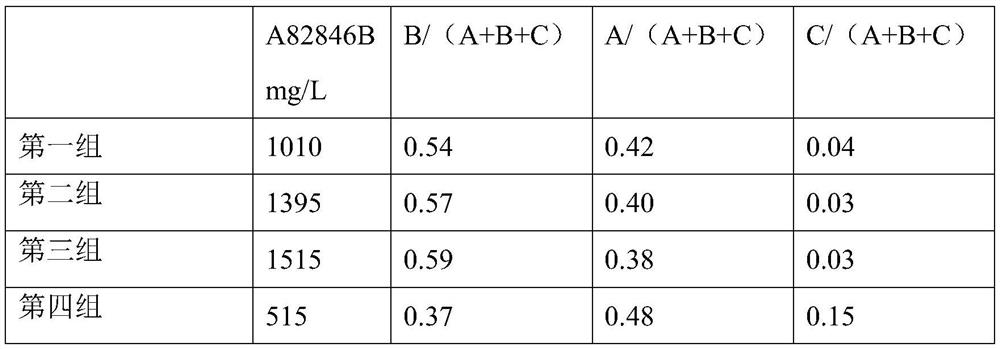

[0038] Inoculate 3.5L of mature shake flask seeds into a fermenter with 35L of feed liquid, culture conditions: temperature 30°C, ventilation volume 1VVM, tank pressure 0.05Mpa, initial speed 200rpm, and control the dissolved oxygen above 30% by adjusting the speed. Cultivate for 5 days to obtain a fermented liquid, and the fermentation unit is 515 mg / L.

Embodiment 3

[0040] The fermented liquid obtained in Example 2 was adjusted to pH=10.3 with NaOH solution, stirred for 2 hours, and plate-and-frame press-filtered to obtain 35 L of press-filtered liquid, which was adjusted to pH=9.2, and then introduced into LX18 adsorption resin. After purifying 9L of resin with water with a pH of 8, desorb with 8L of 1.0% acetic acid aqueous solution, and mix the components with a concentration greater than 500mg / L to form a primary desorption mixture, then perform nanofiltration on the desorption mixture, and concentrate to The unit is 35000mg / L.

[0041] The concentrated solution is introduced into the C18 column that has been balanced, and the eluent (5% acetonitrile: 0.5% NH 4 h 2 PO 4=3:97 (v / v)) for elution, and the components with a purity of more than 90% were collected for extracting the product. A82846B purity below 90% is impurity waste liquid.

[0042] Collect the impurity waste liquid, concentrate it by nanofiltration, and concentrate un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com