A method for efficiently fermenting and producing macrolide compound fw05328-1

A technology for macrocyclic lactams and compounds, which is applied in the field of high-efficiency fermentation to produce macrocyclic lactam compound FW05328-1, which can solve the problems of low fermentation titer and product ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preserved Micromonospora marine strain Micromonospora sp.FIM-MA181224 was cultured on a high asparagine solid medium at 35°C for 15 days to obtain a fresh slant of Micromonospora marine micromonospora sp.FIM-MA181224.

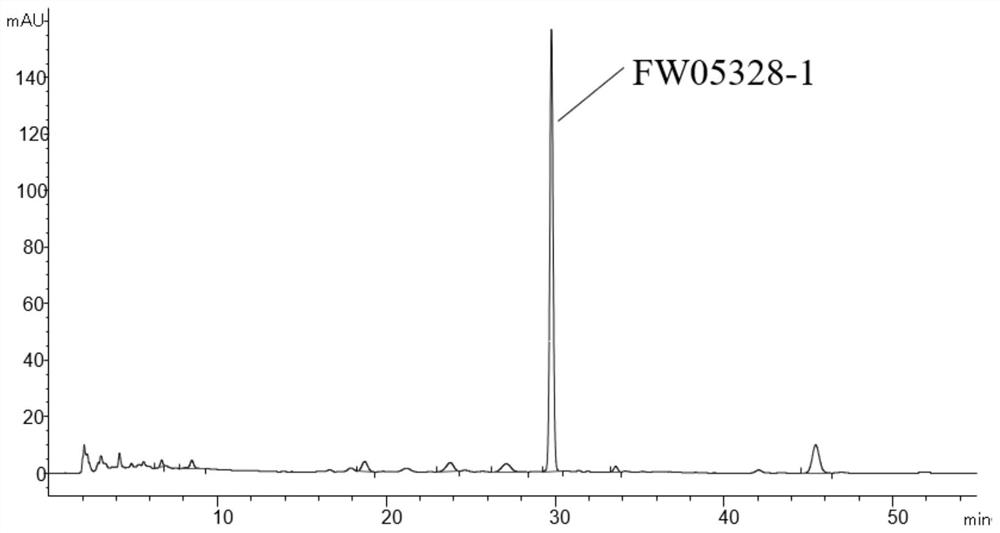

[0037] Inoculate the fresh slanted pieces (0.5cm×0.5cm) of Micromonospora marine Micromonospora sp.FIM-MA181224 in the shake flask seed medium, and cultivate them at 28°C and 220r / min for 72h to obtain the shake flask seeds. Inoculate the shake flask fermentation medium with 4% inoculum amount, culture it at 28°C and 220r / min for 6 days, put it into the bottle, and measure the content and component ratio of FW05328-1 in the fermentation broth by HPLC method.

[0038] The seed medium preparation method: cornstarch 6g, peptone 5g, soybean meal 5g, yeast powder 3g, K 2 HPO 4 ·3H 2 O 0.5g, CaCO 3 1g, 16g sea salt, 1L tap water, adjust the pH value to pH7.2.

[0039] Fermentation medium preparation method: soluble starch 10g, peptone 5g, soybean cake...

Embodiment 2

[0055] In this embodiment, the fermentation medium in the fermentation method is further optimized, and a more suitable seed liquid medium and fermentation medium are screened out.

[0056] The fermentation method of the compound FW05328-1 described in this example is the same as in Example 1, the only difference being:

[0057] Described seed medium composition and content are as follows: soluble starch 18g, glucose 6g, peptone 4g, yeast powder 5g, (NH 4 ) 2 SO 4 0.5g, K 2 HPO 4 ·3H 2 O 0.5g, CaCO 3 2.0g, sea salt 16g, tap water 1L, adjust the pH value to pH7.2;

[0058] The composition and content of the fermentation medium are as follows: soluble starch 16g, glucose 4g, peptone 6g, soybean cake powder 2.5g, yeast powder 2g, K 2 HPO 4 ·3H 2 O 0.5g, (NH 4 ) 2 SO 4 0.5g, CaCO 3 1.0g, sea salt 10g, 3-aminobutyric acid 0.1g, tap water 1L, adjust the pH value to 6.6.

Embodiment 3

[0067] Embodiment 3 10L fermentation tank fermentation culture

[0068]The preserved Micromonospora marine strain Micromonospora sp.FIM-MA181224 was cultured on a high asparagine solid medium at 35°C for 15 days to obtain a fresh slant of Micromonospora marine micromonospora sp.FIM-MA181224.

[0069] Inoculate the shake flask seed medium with fresh slanted excavated pieces (0.5 cm×0.5 cm) of Micromonospora sp. FIM-MA181224, and culture them at 28° C. and 220 r / min for 72 hours to obtain shake flask seeds.

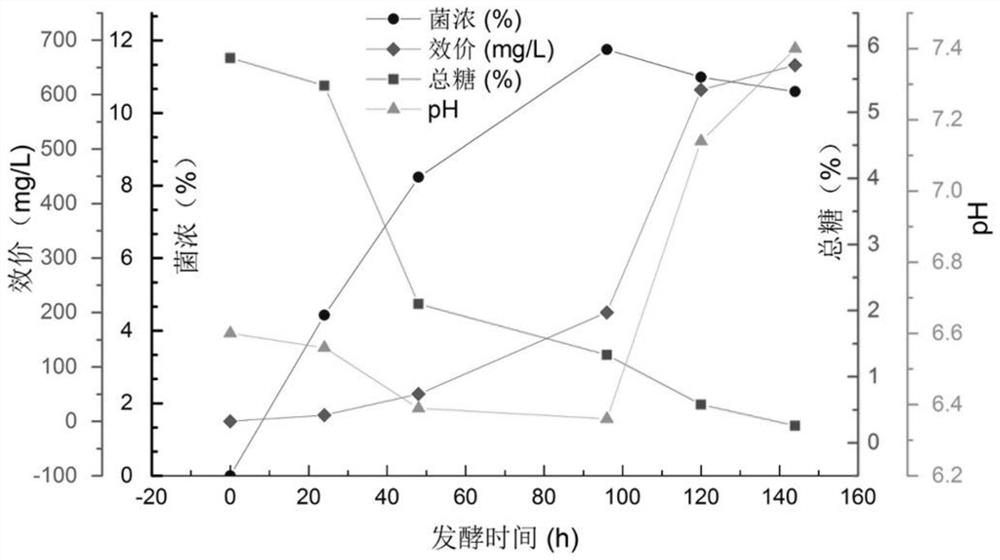

[0070] Inoculate the above-mentioned cultivated shake flask seeds into a 10L fermenter with an inoculum amount of 1.5%, the medium capacity of the fermenter is 7L, the fermentation temperature is 28°C, the tank pressure is 0.03Mpa, and the rotation speed is controlled at 180r / min for 0-48 hours of fermentation. The volume is 1:1.0vvm. With the growth of mycelia, when the bacterial concentration reaches 7% after about 48 hours of fermentation, increase the speed to 200r / min,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com