A kind of caulking structure with modified isocyanate buffer layer and its construction technology

A technology of isocyanate and construction technology, applied in coatings, polyurea/polyurethane coatings, bridges, etc., can solve problems such as excessive moisture content in concrete, shedding, large difference in hardness between primer and elastomer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

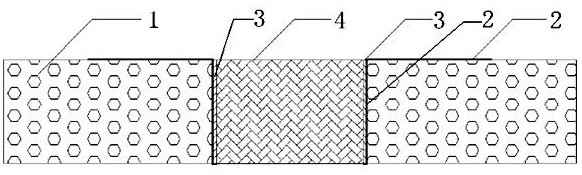

[0075] An epoxy primer 2 is provided on the upper edge and side of the concrete joint 1, and an elastomer is poured between the side primer 2, and the 100% tensile elastic modulus of the elastomer is ≤0.2MPa;

Embodiment 2

[0077] An epoxy primer 2 is provided on the upper edge and side of the concrete joint 1, and a buffer layer 3 is provided on the side primer 2. The buffer layer 3 has a 100% tensile modulus of elasticity of 1.5MPa and a hardness of 38A. The elastic body 4 is poured between the buffer layers 3, and the 100% tensile elastic modulus of the elastic body 4 is ≤0.2MPa.

Embodiment 3

[0079] An epoxy primer 2 is provided on the upper edge and side of the concrete joint 1, and a buffer layer 3 is provided on the side primer 2. The buffer layer 3 has a 100% tensile modulus of elasticity of 2.5MPa and a hardness of 45A. The elastic body 4 is poured between the buffer layers 3, and the 100% tensile elastic modulus of the elastic body 4 is ≤0.2MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com