Tantalum carbide ceramic precursor synthesis method and obtained tantalum carbide ceramics

A technology of a ceramic precursor and a synthesis method, applied in the field of tantalum carbide ceramics, can solve the problems of carbon fiber surface damage, affecting the mechanical properties and high temperature resistance of composite materials, and achieve the effects of improving high temperature resistance, low cost and improving mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In a high-purity argon environment, 9.0g (0.025mol) of tantalum source compound (TaCl 5 ) into the three-necked flask. Add 100mL triethylamine and 3.0g (0.05mol) ethylenediamine, and stir well, react at room temperature for 4h. The temperature was raised to 320° C., kept for 1 hour, and cooled to obtain a black, brittle tantalum carbide precursor with a synthesis yield of 50.2%.

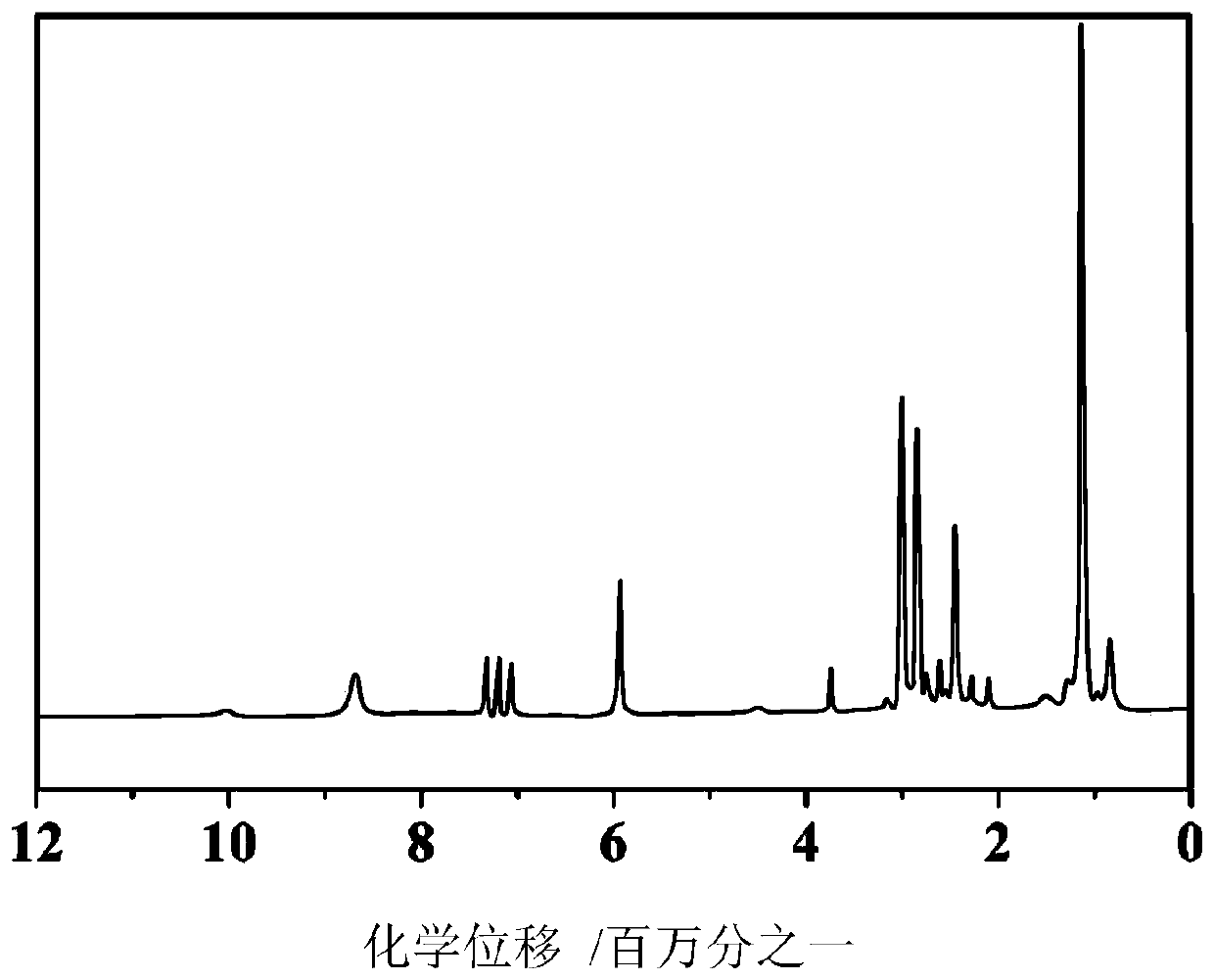

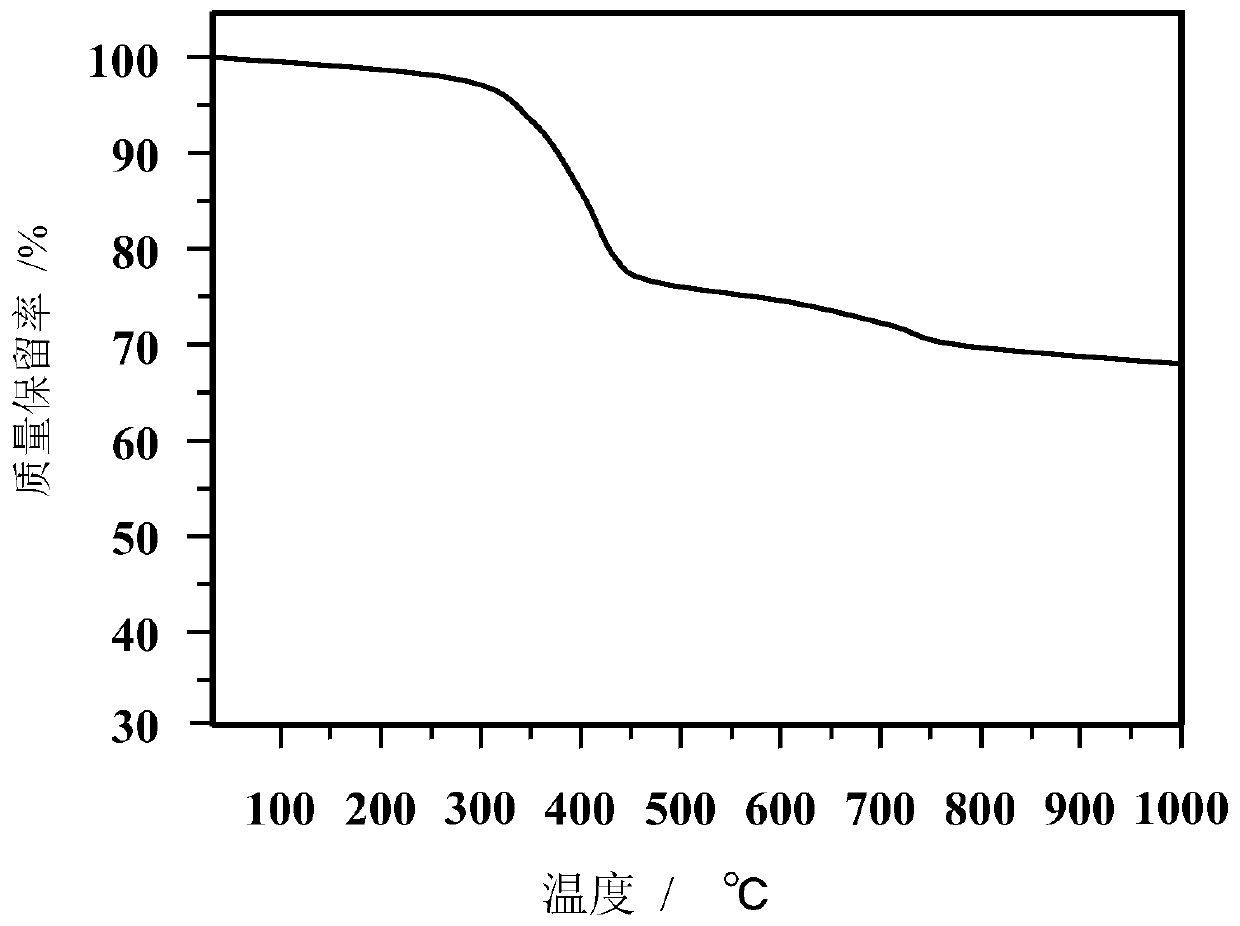

[0029] Result analysis: measure the thermogravimetric curve, nuclear magnetic resonance spectrogram, infrared spectrogram, X-ray diffraction spectrogram of embodiment 1 gained product respectively by existing method, gained result is listed in Figure 1~4 middle.

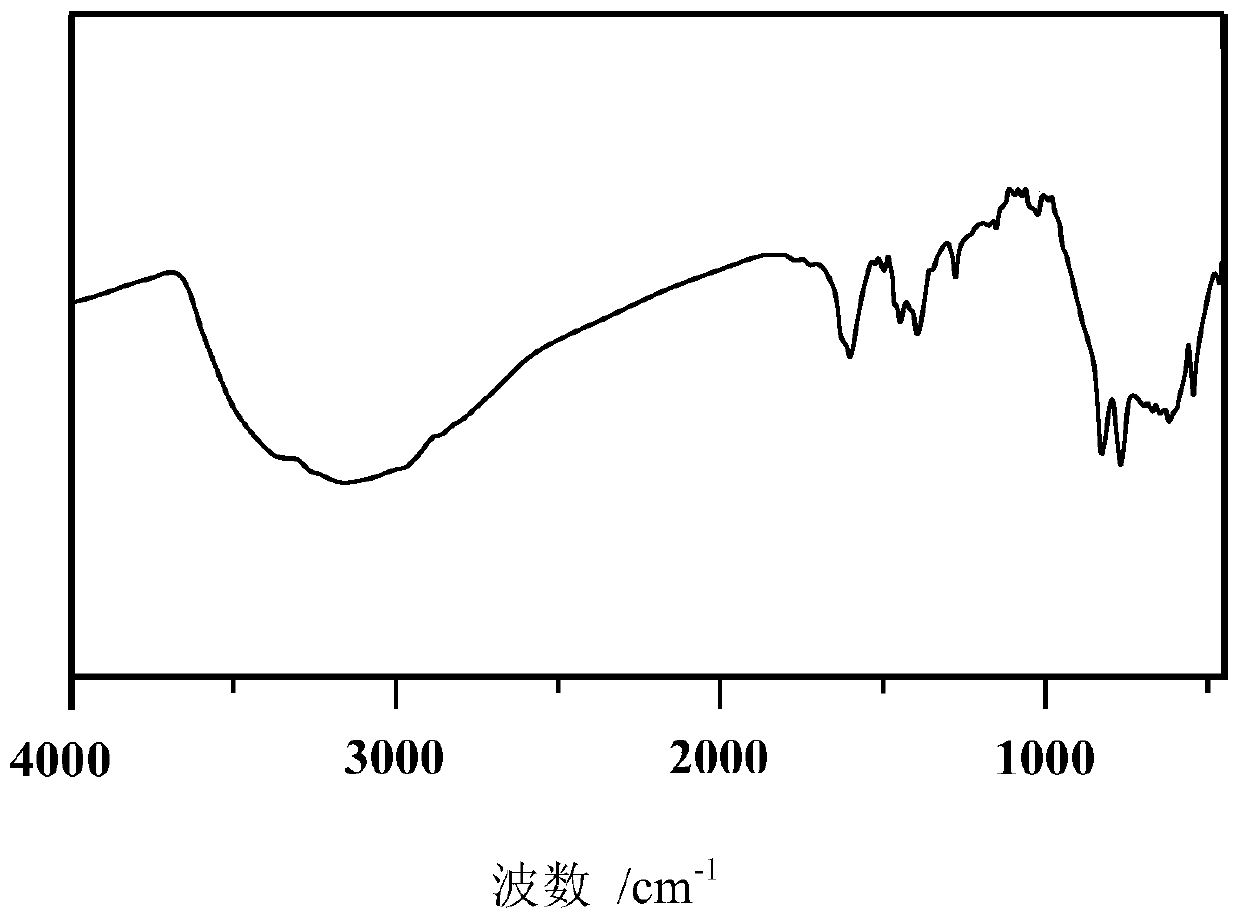

[0030] figure 1 It is the infrared spectrogram (FT IR) of the tantalum carbide precursor obtained in Example 1. Among them, the corresponding group of the main absorption peak can be attributed to: 3429cm -1 、3383cm -1 、3164cm -1 (ν(C-H(-CH 2 )) and ν(N-H)), 2955cm -1 、2858cm -1 (ν(C-H)); 1609cm -1 (δ(N-H)), 1452cm -1 (δ...

Embodiment 2

[0035] In a high-purity argon environment, 14.5g (0.025mol) of tantalum source compound (TaBr 5 ) into the three-necked flask. Add 100mL triethylamine and 16.0g (0.1mol) N,N'-bis(2-aminoethyl)-1,3-propanediamine (C 7 h 20 N 4), and fully stirred, reacted at room temperature for 6h. Raise the temperature to 300°C, hold the temperature for 2 hours, and cool to obtain a black, brittle tantalum carbide precursor. The synthesis yield is 46.8%, and the ceramic yield is about 66% at 1000°C.

Embodiment 3

[0037] The difference with Example 1 is: the molar ratio of Ta-X bond and N-H bond is 1:5, and the tantalum source compound is TaI 5 , the polyamine compound is propylene diamine; stirring and reacting for 8 hours, then raising the temperature to 350° C., keeping the temperature for 4 hours, and cooling to room temperature to obtain a tantalum carbide ceramic precursor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com