A multifunctional vibration contact testing machine

A contact test, multi-functional technology, used in vibration testing, machine/structural component testing, measuring devices, etc., to solve problems such as micro-cracks in the contact area, large space occupied by weights, and errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

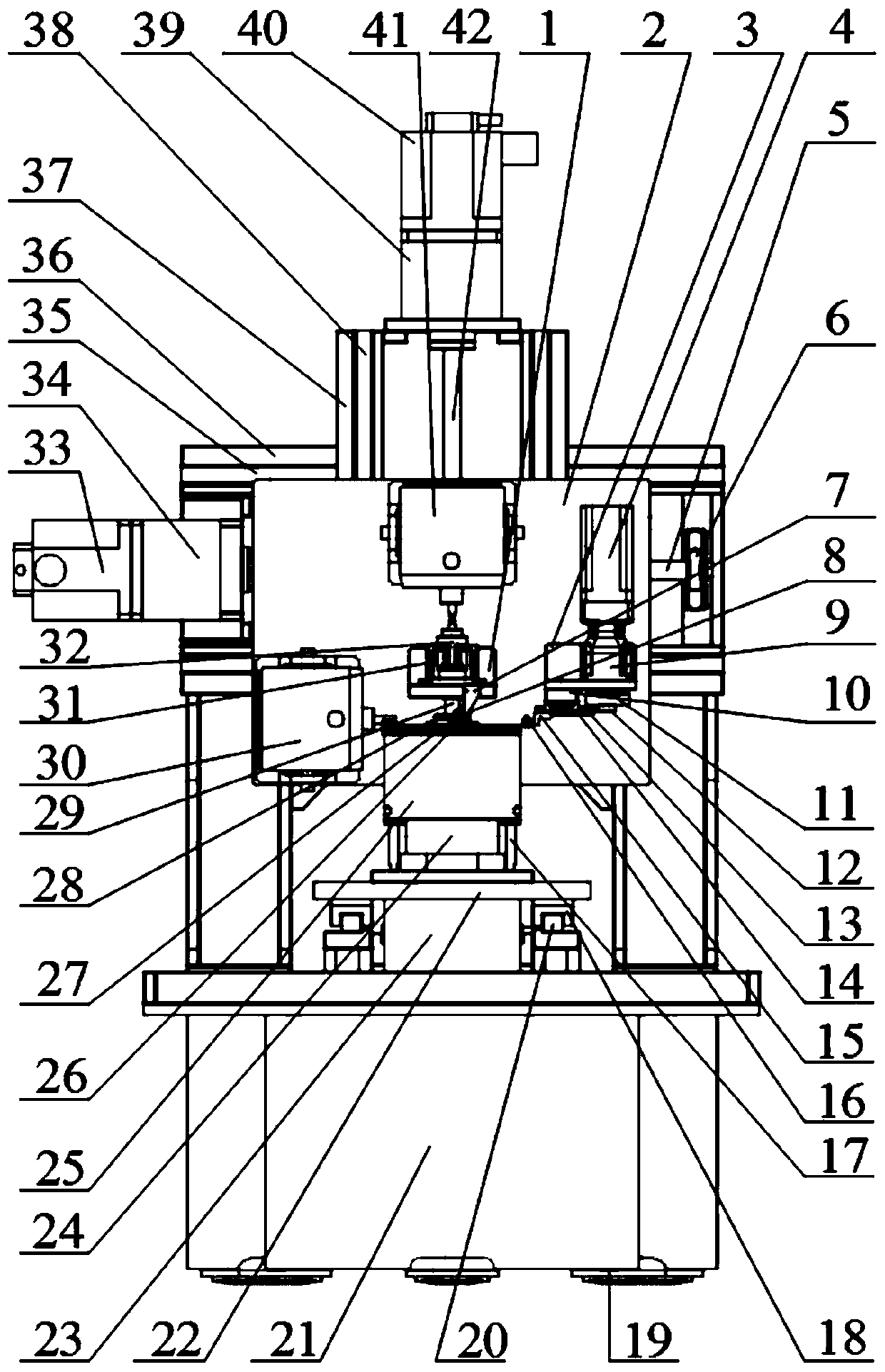

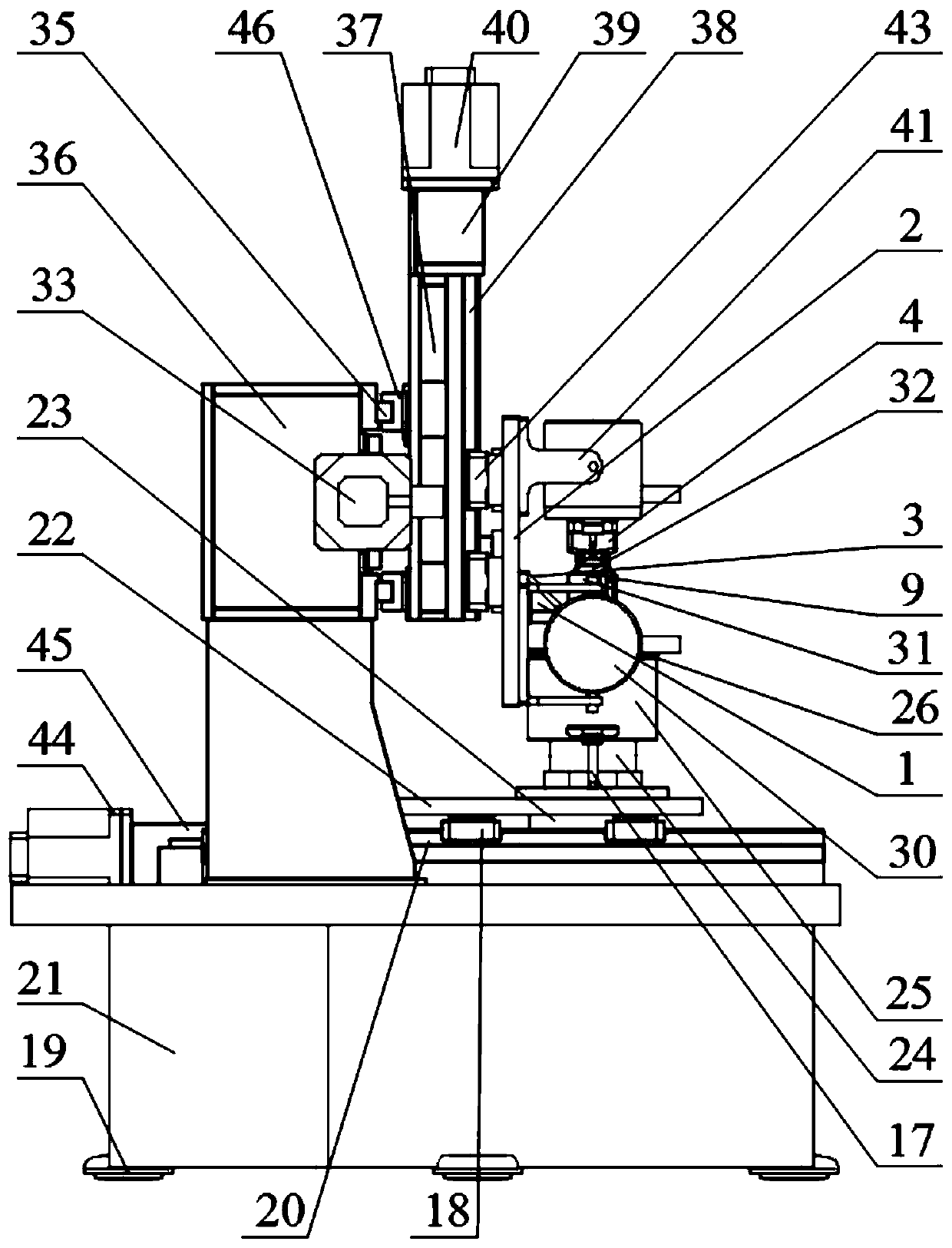

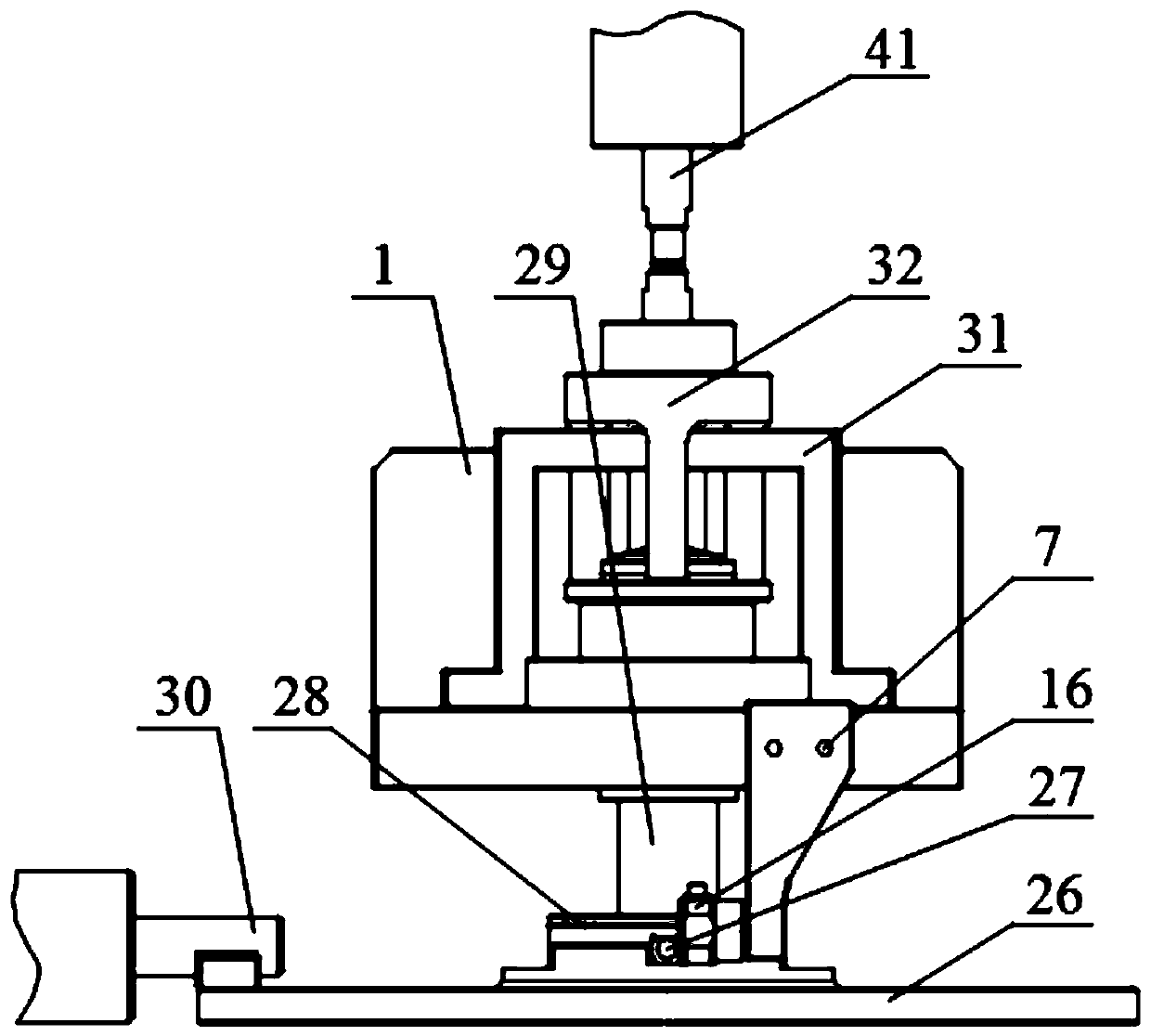

[0042] Please refer to figure 1 and figure 2 , a multifunctional vibration contact testing machine provided by the present invention, the testing machine includes a body, a transmission system, a rotating system, a test piece installation and lubrication system, an exciting load system, a measurement and acquisition system, and a display and control system, wherein: The body includes a platform frame 21, a standing frame 36 and an adjustment foot pad 19; the transmission system includes the first linear guide rail 20, the first linear guide rail slider 18, the first lead screw, the first lead screw holder, The first servo motor mounting base 45, the first servo motor 44, the first coupling, the second linear guide rail 35, the second linear guide rail slider 46, the second trapezoidal screw 5, the second trapezoidal screw fixing seat 6, The second servo motor 33, the second servo motor mount 34, the second coupling, the lateral movement bracket 37, the third linear guide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com