Mask, grating and manufacturing method thereof

A mask and grating technology, applied in the field of grating and production, can solve the problems of high cost, limited grating accuracy, and difficult light source technology, and achieve the effects of small period, improved resolution, and small area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

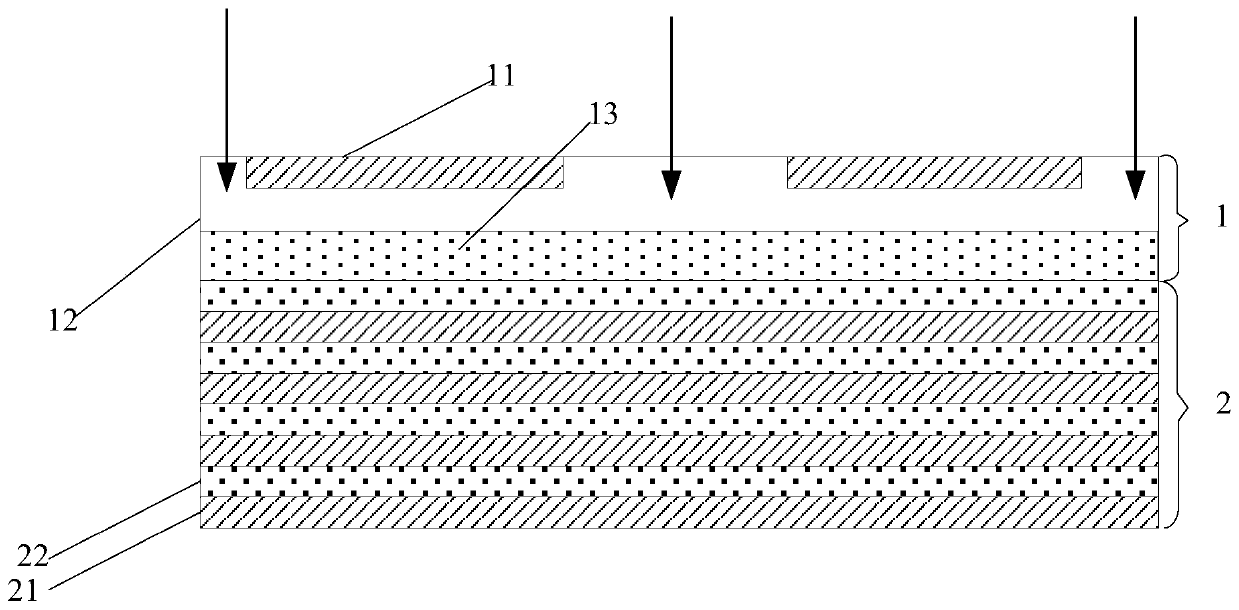

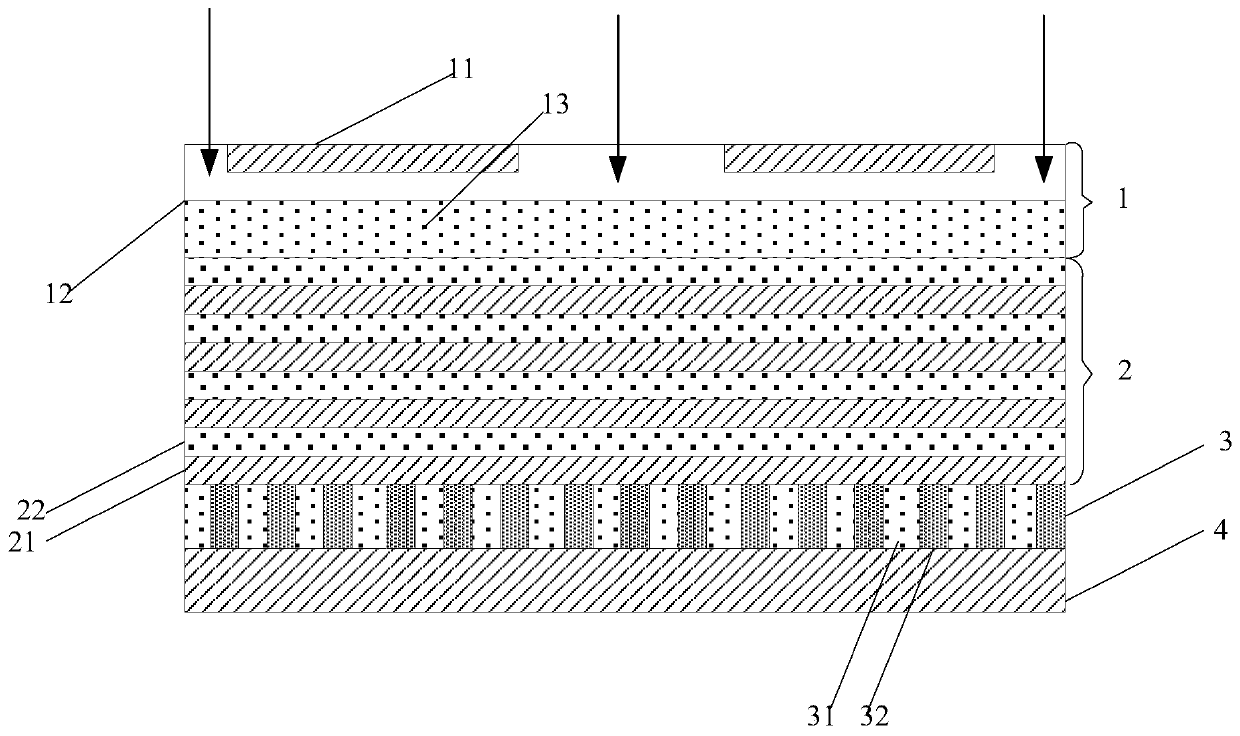

[0037] In order to make the technical problems, technical solutions and advantages to be solved by the embodiments of the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0038] With the vigorous development of modern processing technology, the grating manufacturing process is developing towards high precision, low cost, and large output. At present, the following methods are mainly used to process high-precision gratings: traditional photolithography, electron beam direct writing, nanoimprinting, etc. . The most commonly used production method is traditional lithography. The principle is to expose the photoresist through a mask to obtain an exposure pattern with micron resolution. Because the light has a diffraction effect when passing through the mask, traditional lithography The resolution of the pattern is on the order of the exposure wavelength. To obtain a higher-resolution grating, a shorter wav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com