Novel insulation tube type bus of 35kv and below, and manufacture technology thereof

A production process and technology of insulating tubes, which are applied in the directions of insulating cables, insulating conductors, and insulating conductors/cables, etc., can solve the problems of insufficient uniform structure, difficult to meet the requirements of cables, unsuitable for waterproofing and narrowness, etc., and reduce construction costs. The effect of difficulty, reduction of joints, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

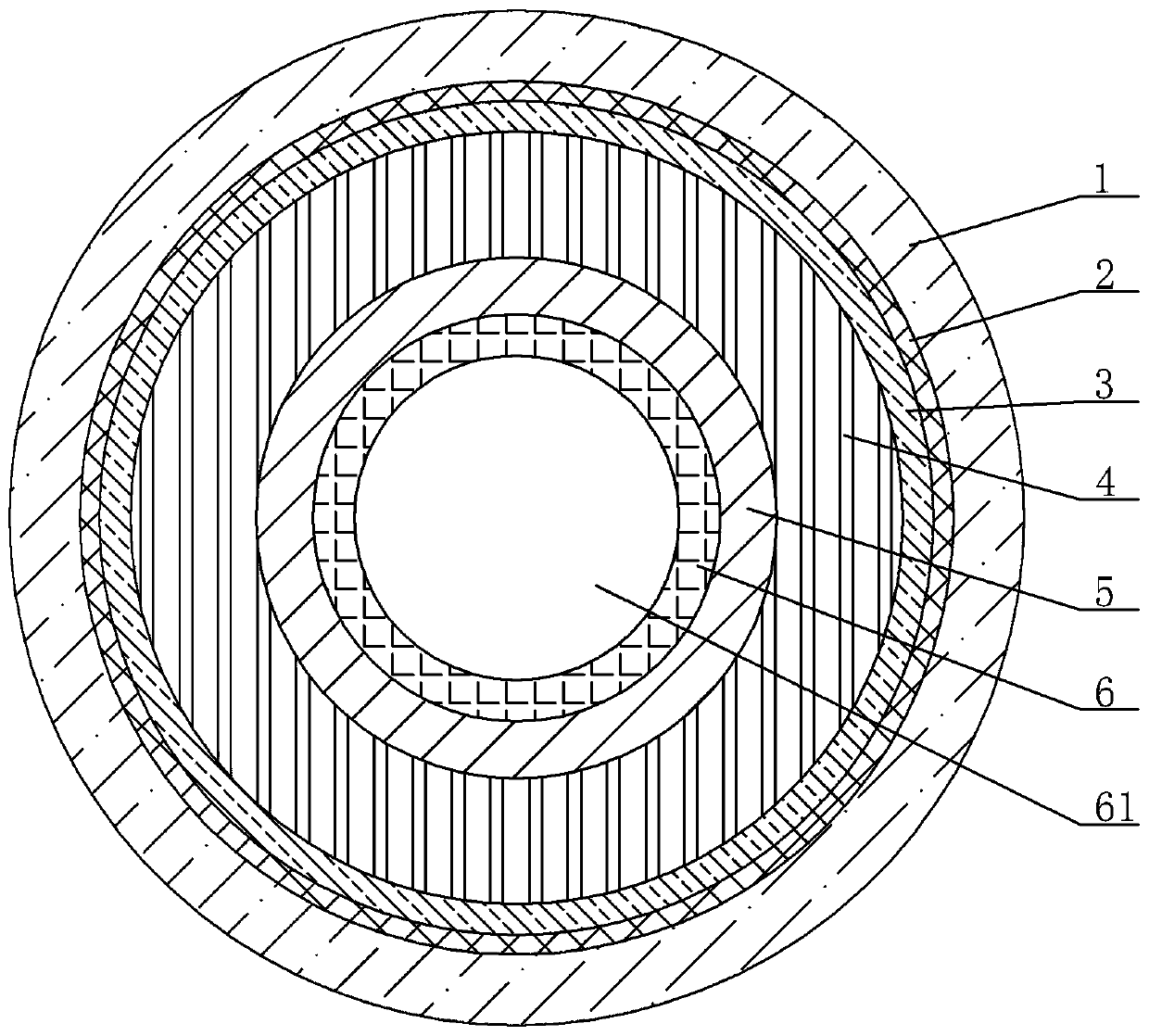

[0028] A new type of insulated tubular busbar of 35kv and below, see figure 1 : It includes an outer sheath 1, a metal shielding layer 2, an outer shielding layer 3, an insulating layer 4, an inner shielding layer 5, a tubular copper conductor 6, and a tubular copper conductor, which are arranged in sequence from the outside to the inside. The center of 6 is a cavity structure 61, the outer ring surface of the tubular copper conductor 6 is covered with an inner shielding layer 5, the outer ring surface of the inner shielding layer 5 is covered with an insulating layer 4, and the outer ring surface of the insulating layer 4 is covered There is an outer shielding layer 3 , the outer ring surface of the outer shielding layer 3 is covered with a metal shielding layer 2 , and the outer ring surface of the metal shielding layer 2 is covered with an outer sheath 1 .

[0029] The tubular copper conductor 6 is specifically a high-conductivity copper tube, and the cross-sectional area o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com