Laser etched pump light stripper and manufacturing method thereof

A technology of laser etching and manufacturing method, which is applied to laser parts, gas laser parts, optical waveguides and light guides, etc., can solve the problems of difficult cladding light stripping, poor control accuracy of optical fibers, and high toxicity of chemical agents. , to achieve the effect of cladding light filtering, not easy to be burned out, and solve the effect of high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

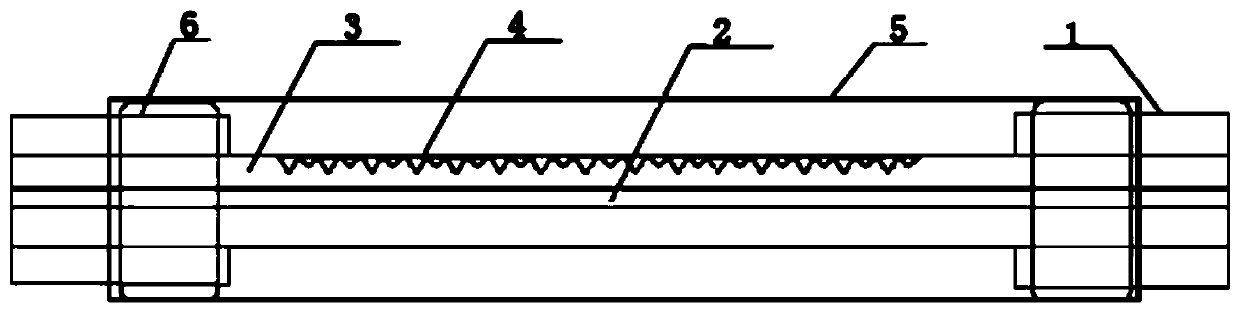

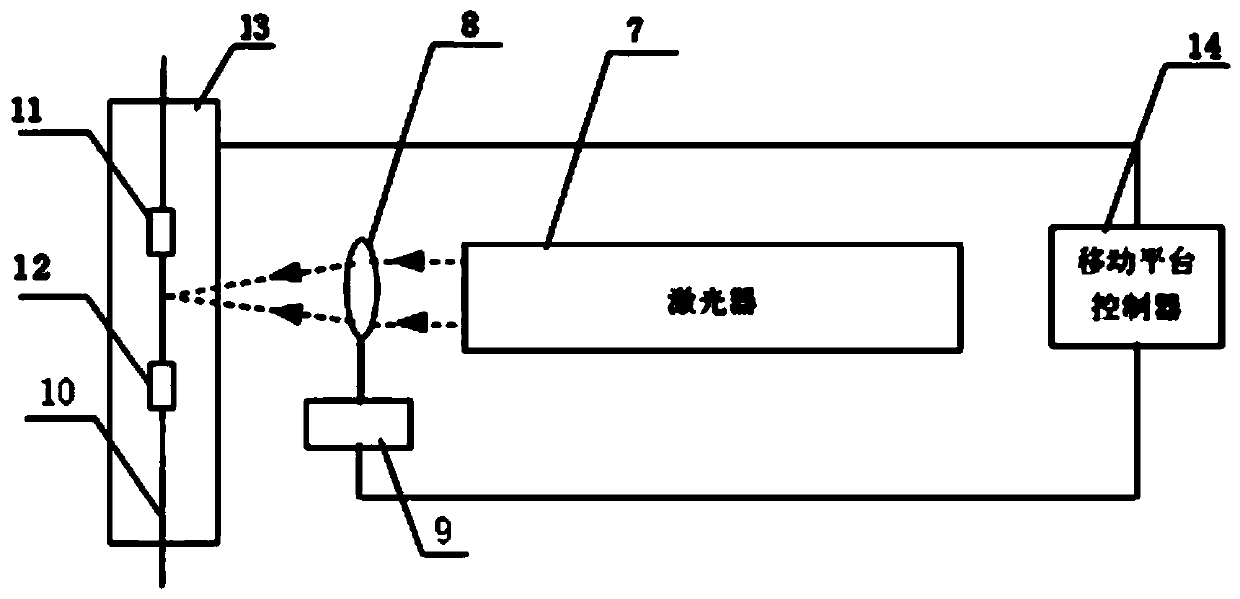

[0024] The invention provides a laser-etched pumping light stripper, which includes a fiber core and an optical fiber cladding. The optical fiber cladding wraps the fiber core, and the outer surface of the optical fiber cladding is provided with a plurality of grooves. The groove can lead the pump light and stray light in the cladding of the fiber into the air here to improve the beam quality.

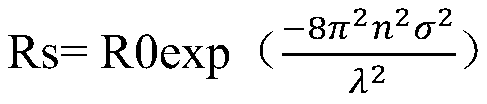

[0025] In this embodiment, the grooves are irregularly distributed on the outer surface of the optical fiber cladding. The more irregular the groove, that is, the rougher the outer surface of the fiber cladding, the higher the attenuation coefficient of the pump light in the fiber cladding. If the scattering coefficient is Rd, the ideal reflection coefficient is R0, the actual reflection coefficient is Rs, σ is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com