Filtering structure and preparation method of filtering structure

A filter structure and filter material technology, applied in chemical instruments and methods, semi-permeable membrane separation, membrane technology, etc., can solve the problems of poor support structure strength, poor filter structure strength, small effective filter area, etc., and achieve negative pressure resistance Good, the porosity is improved, and the effect of increasing the effective filtration area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

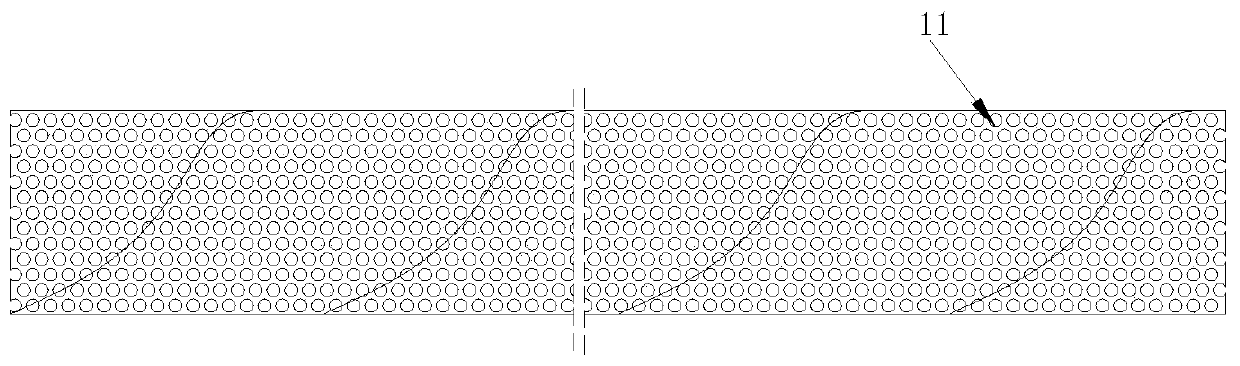

[0177] like figure 2 The supporting structure of the shown filter structure includes a support cylinder 1 wound by a strip-shaped coiled material 11, the coiled material 11 has a porous structure, the coiled material 11 is rectangular, and the center of the coiled material 11 The wire is wound in the shape of a cylindrical helix. The thickness of the coiled material 11 is 0.6 mm, and the porosity is 50%. The helix angle α of the helix is 75°. The two long sides of the coil 11 are wound and formed by contact welding, and the width of the welding is 3mm. When the helix angle α is 75° and the middle diameter of the support cylinder 1 is 126 mm, the required width of the coil 11 is 102.39 mm.

Embodiment 2

[0179] like figure 2 The supporting structure of the shown filter structure includes a support cylinder 1 wound by a strip-shaped coiled material 11, the coiled material 11 has a porous structure, the coiled material 11 is rectangular, and the center of the coiled material 11 The wire is wound in the shape of a cylindrical helix. The thickness of the coiled material 11 is 0.8mm, and the porosity is 70%. The helix angle α of the helix is 60°. The two long sides of the coil 11 are wound and formed by contact welding, and the width of the welding is 3mm. When the helix angle α is 60° and the middle diameter of the support cylinder 1 is 126 mm, the required width of the coil 11 is 197.82 mm.

Embodiment 3

[0181] like figure 2 The supporting structure of the shown filter structure includes a support cylinder 1 wound by a strip-shaped coiled material 11, the coiled material 11 has a porous structure, the coiled material 11 is rectangular, and the center of the coiled material 11 The wire is wound in the shape of a cylindrical helix. The thickness of the coiled material 11 is 1mm, and the porosity is 80%. The helix angle α of the helix is 50°. The two long sides of the coil 11 are wound and formed by contact welding, and the width of the welding is 3mm. When the helix angle α is 50° and the middle diameter of the support cylinder 1 is 126 mm, the required width of the coil 11 is 254.31 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Helix angle α | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com