Large-stroke high-precision laser cutting machine based on permanent magnet linear motor servo system

A permanent magnet linear motor, laser cutting machine technology, applied in the direction of propulsion system, laser welding equipment, electromechanical devices, etc., can solve the problems of parts heating, high temperature damage of parts, etc., to reduce weight, improve performance, and enhance the effect of air circulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

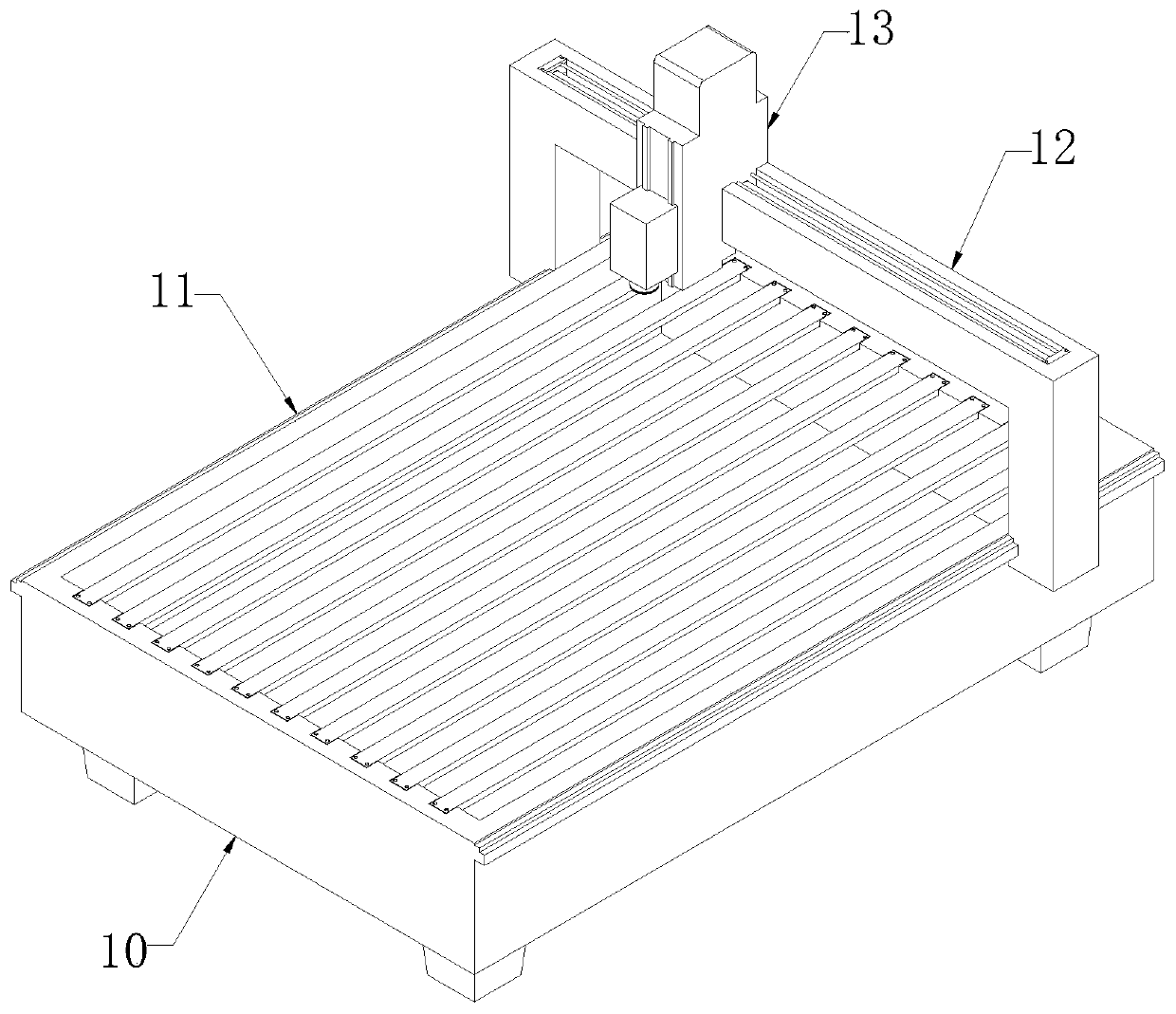

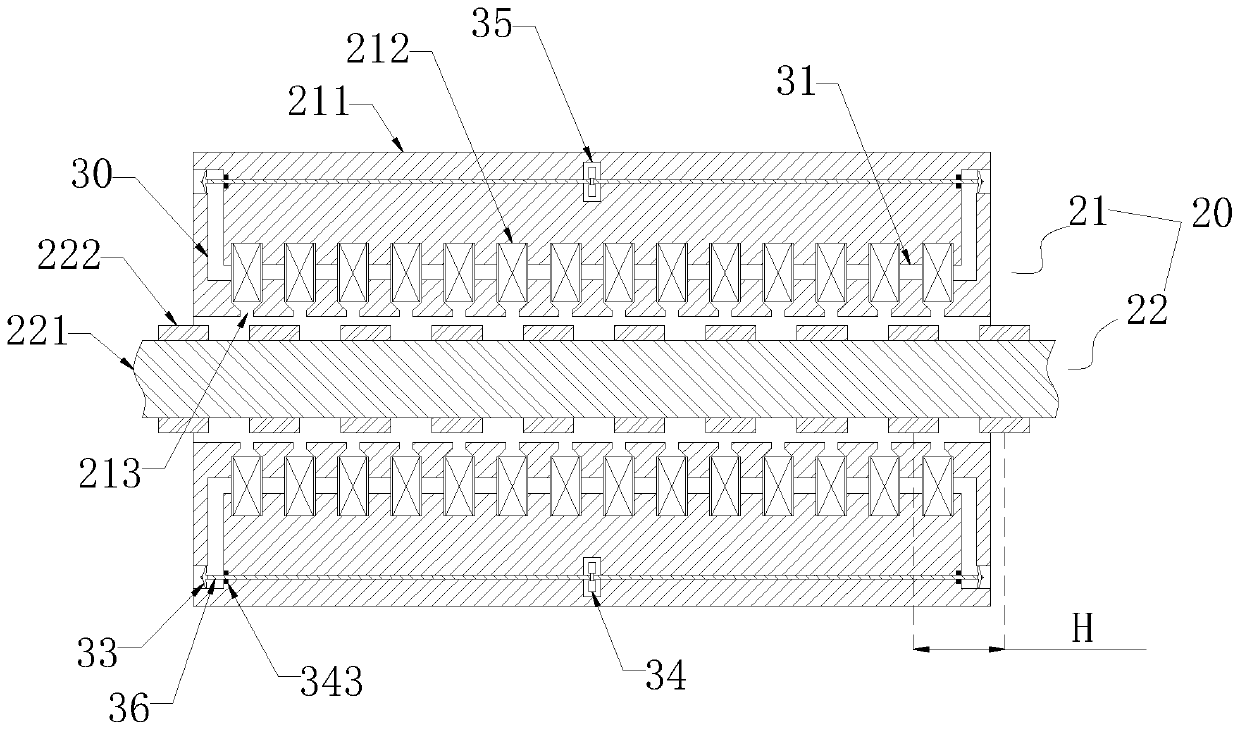

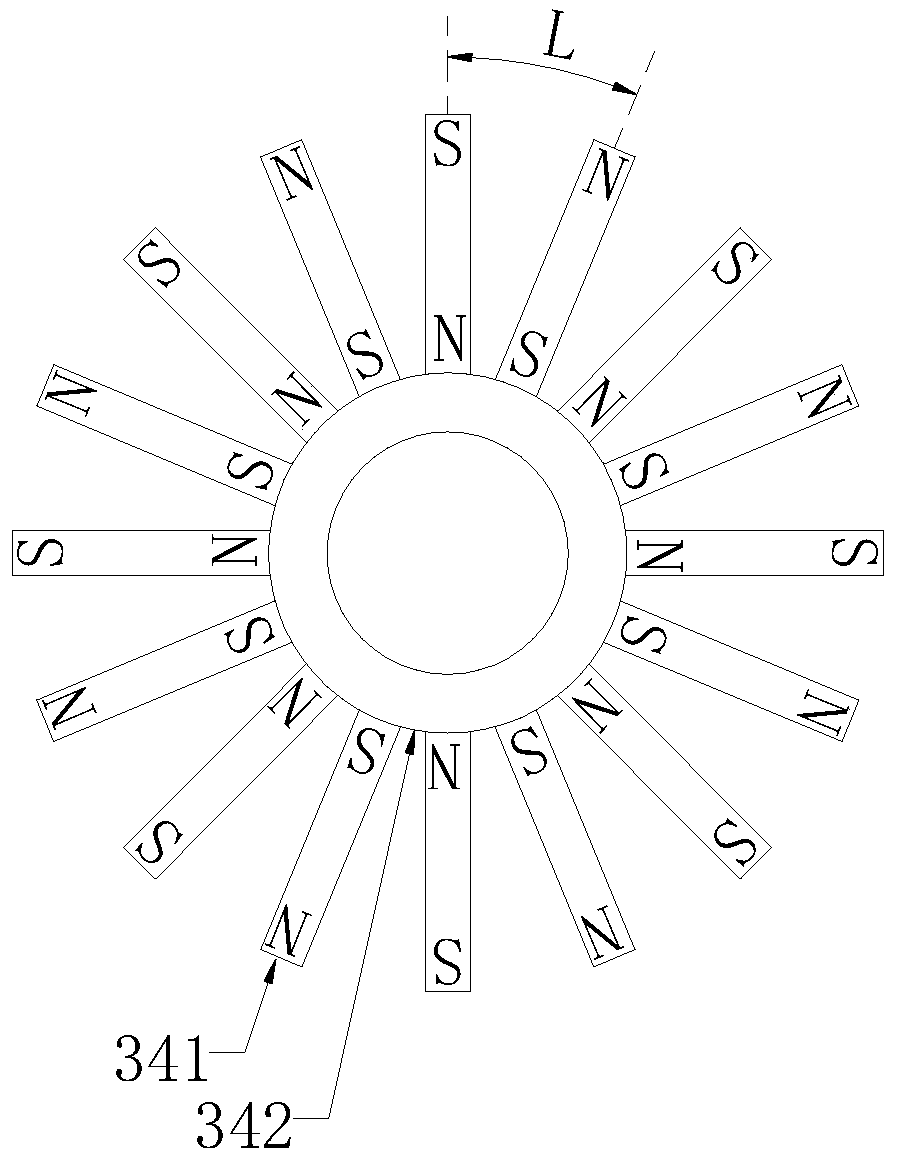

[0024] Such as figure 1 with 2 As shown, the large-stroke high-precision laser cutting machine based on the permanent magnet linear motor servo system includes a machine tool 10, horizontal slide rails 11 arranged on both sides of the machine tool 10, a beam 12 slidingly connected to the horizontal slide rail 11, and a beam 12 sliding Connected tool holder 13, a cylindrical linear motor 20 is provided between the horizontal slide rail 11 and the beam 12, the horizontal slide rail 11 and the beam 12 are slidingly connected by a cylindrical linear motor 20, and the cylindrical linear motor 20 At the same time, it is arranged between the beam 12 and the knife seat 13, and the beam 12 and the knife seat 13 are slidingly connected by a cylindrical linear motor 20; the cylindrical linear motor 20 includes a primary 21 and a secondary 22 arranged in the primary 21, The primary 21 includes a primary iron core 211 and a motor winding 212, the primary iron core 211 is cylindrical, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com