Annular gasket device for small-caliber pipe welding

A small-diameter, gasket technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of inappropriate small-diameter pipeline welding, inability to install pipeline welding counterparts, and narrow radial space, etc. Simple, less parts and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

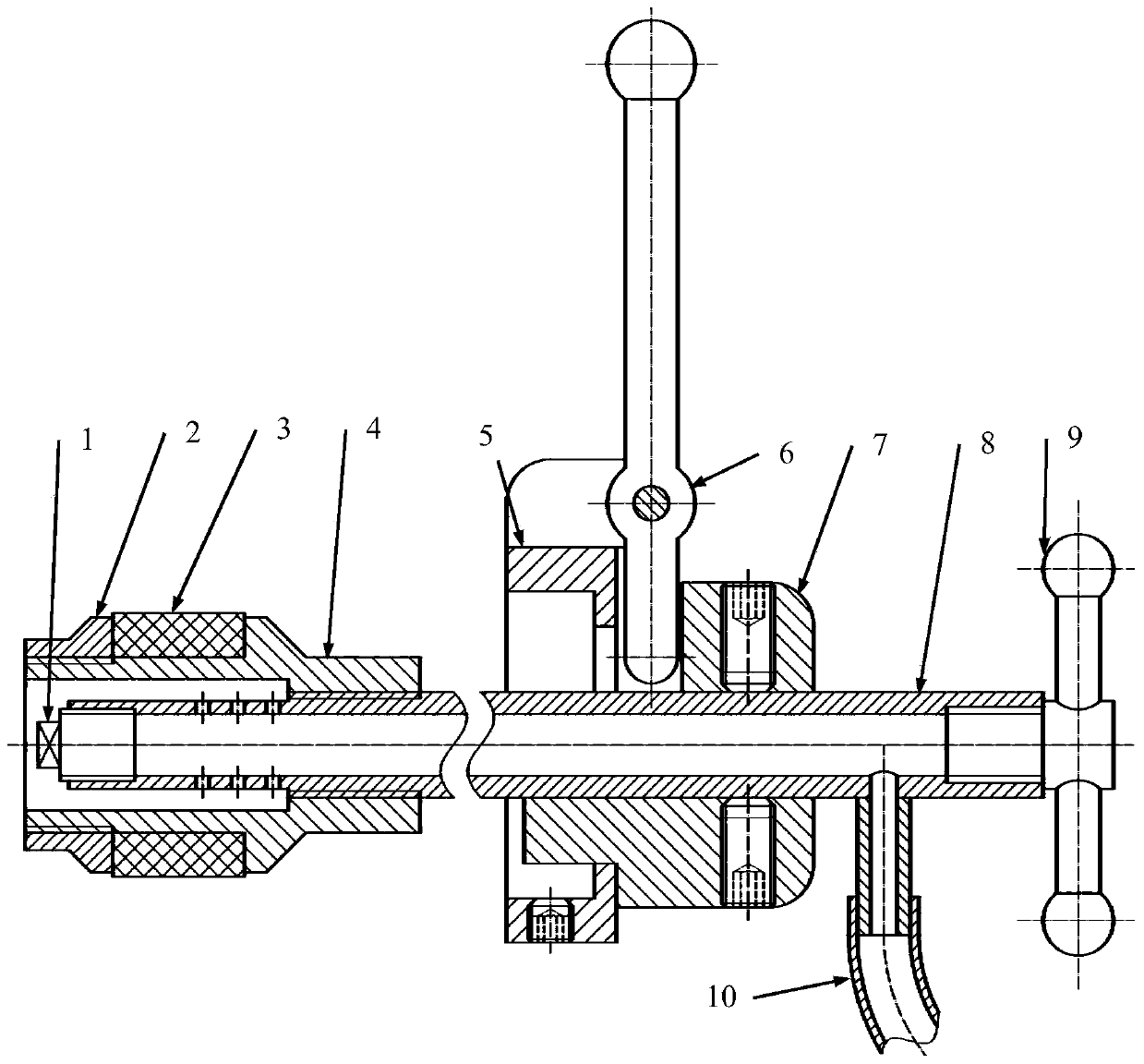

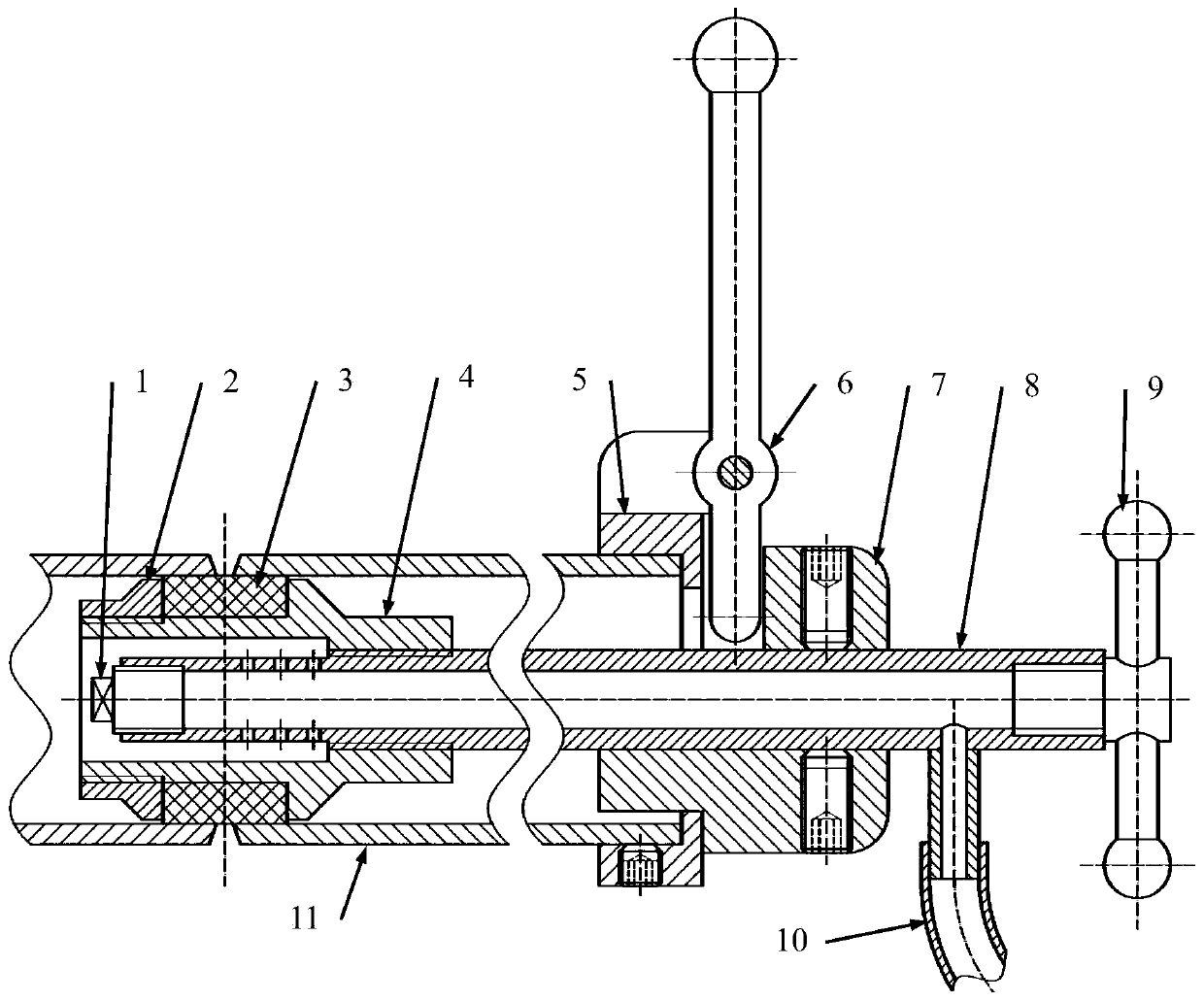

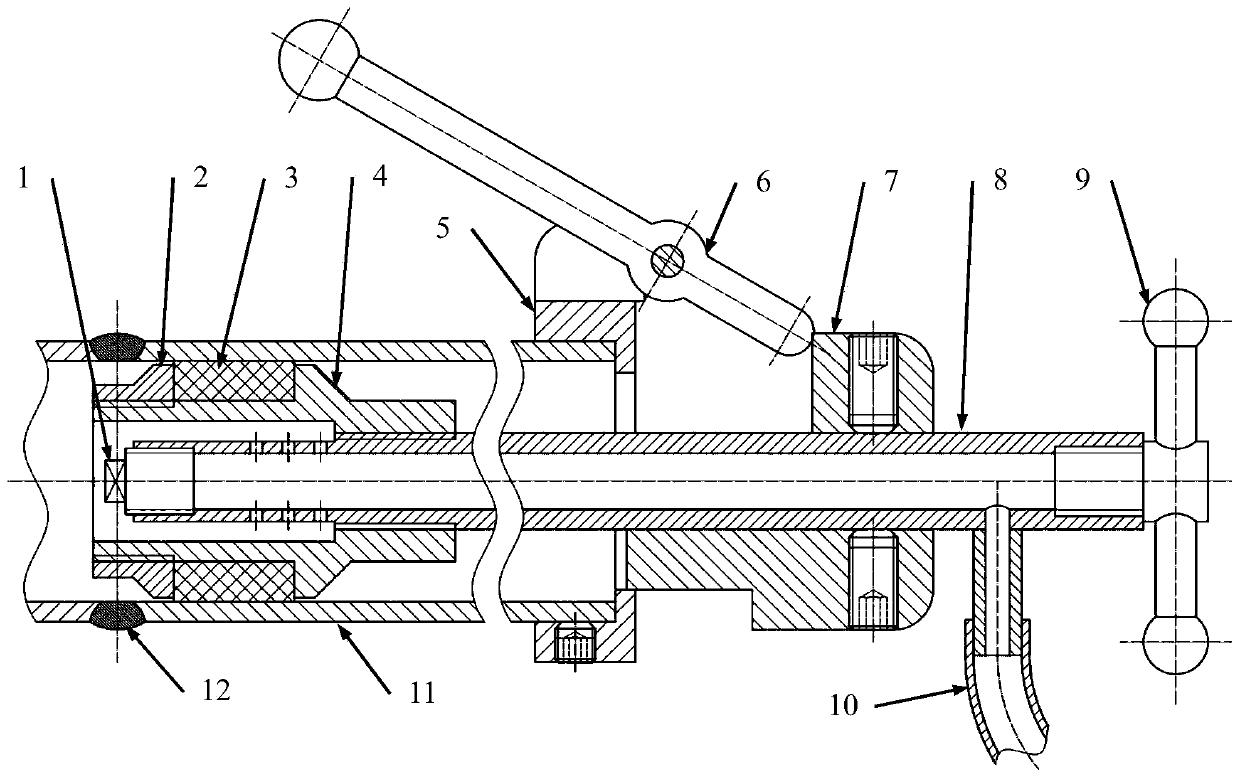

[0032] The present invention will be further described below in conjunction with accompanying drawing:

[0033] Depend on Figure 1 to Figure 15 As shown, what the present invention develops is a liner device used during welding construction of small-diameter pipelines. The structure of the device is relatively simple, and it is easy to disassemble and assemble during the pipeline welding process.

[0034] The technical solution adopted by the present invention to solve its technical problems is: the device consists of a sealing plug, a gasket pressure ring, an annular gasket, a gasket support tube, a crowbar bracket, a crowbar wrench, a support push ring, and a long connecting cylinder , push-pull handle, ten main parts of the air compressor, and common and standard parts such as pin shafts and jacking screws.

[0035] The sealing plug is used to block the front end of the long connecting cylinder, and is in the shape of an externally threaded cylinder, with a small section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com