Manufacturing method of two-dimensional braided suture composite material gas cylinder

A composite material and manufacturing method technology, applied in textiles and papermaking, sewing equipment, sewing machine components, etc., can solve problems such as easy delamination, and achieve the effect of enhancing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

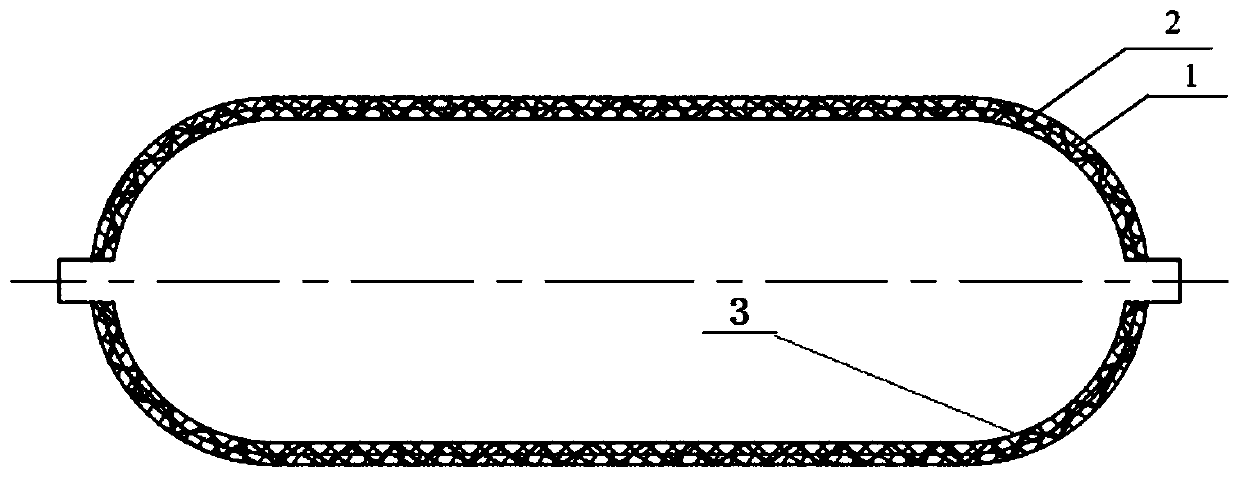

[0022] Embodiment 1, a method for manufacturing a two-dimensional braided and sutured composite gas cylinder, the method includes the following steps:

[0023] (1) Prepare a thin-walled metal liner with aluminum alloy as the gas cylinder liner 3, and use the gas cylinder liner 3 as the mandrel. The gas cylinder liner 3 has a diameter of 200 mm and a thickness of 2 mm. Weave back and forth on the machine to obtain a prefabricated part with an overall network structure; when weaving, choose carbon fiber as the weaving yarn, polyimide fiber or Kevlar fiber as the shaft yarn, set the weaving angle to 60°, and weave 20 layers back and forth on the mandrel to form Multi-layer braiding layer 1, the thickness of the prefabricated part is 10mm;

[0024] (2) Use the curved needle suture method, use Kevlar fiber as the suture line 2, set the stitch distance to 5mm, and the line distance to 9mm, and sew the prefabricated parts obtained in the first step into a whole; refer to figure 1 ; ...

Embodiment 2

[0027] Embodiment 2, a method for manufacturing a two-dimensional braided and sutured composite gas cylinder, the method includes the following steps:

[0028] (1) Prepare a thin-walled metal liner with aluminum alloy as the gas cylinder liner 3, use the gas cylinder liner 3 as the mandrel, the diameter of the gas cylinder liner 3 is 300mm, and the thickness is 3mm, on the two-dimensional braiding machine Weave back and forth to obtain a prefabricated part with an overall network structure; when weaving, choose carbon fiber as the weaving yarn, polyimide fiber or Kevlar fiber as the shaft yarn, set the weaving angle to 70°, and weave 40 layers back and forth on the mandrel to form a multi- Layer braiding layer 1, the thickness of the prefabricated part is 12mm;

[0029] (2) Use the curved needle suture method, use Kevlar fiber as the suture line 2, set the stitch distance to 6mm, and the line distance to 11mm, and sew the prefabricated parts obtained in the first step into a w...

Embodiment 3

[0032] Embodiment 3, a method for manufacturing a two-dimensional braided and sutured composite gas cylinder, the method includes the following steps:

[0033] (1) Prepare a thin-walled metal liner with aluminum alloy as the gas cylinder liner 3, use the gas cylinder liner 3 as the mandrel, the diameter of the gas cylinder liner 3 is 250mm, and the thickness is 2mm, on the two-dimensional braiding machine Weave back and forth to obtain a prefabricated part with an overall network structure; when weaving, choose carbon fiber as the weaving yarn, polyimide fiber or Kevlar fiber as the shaft yarn, set the weaving angle to 65°, and weave 30 layers back and forth on the mandrel to form a multi-layer Layer braiding layer 1, the thickness of the prefabricated part is 11mm;

[0034] (2) Use the curved needle suture method, use Kevlar fiber as the suture line 2, set the stitch distance to 5mm, and the line distance to 10mm, and sew the prefabricated parts obtained in the first step int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com