Particle shaping vacuum packing machine

A vacuum packaging machine and particle technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of operation failure, unfavorable bag transportation and storage, restricted use places, etc., to reduce the use conditions, easy to maintain and replace, improve The effect of production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

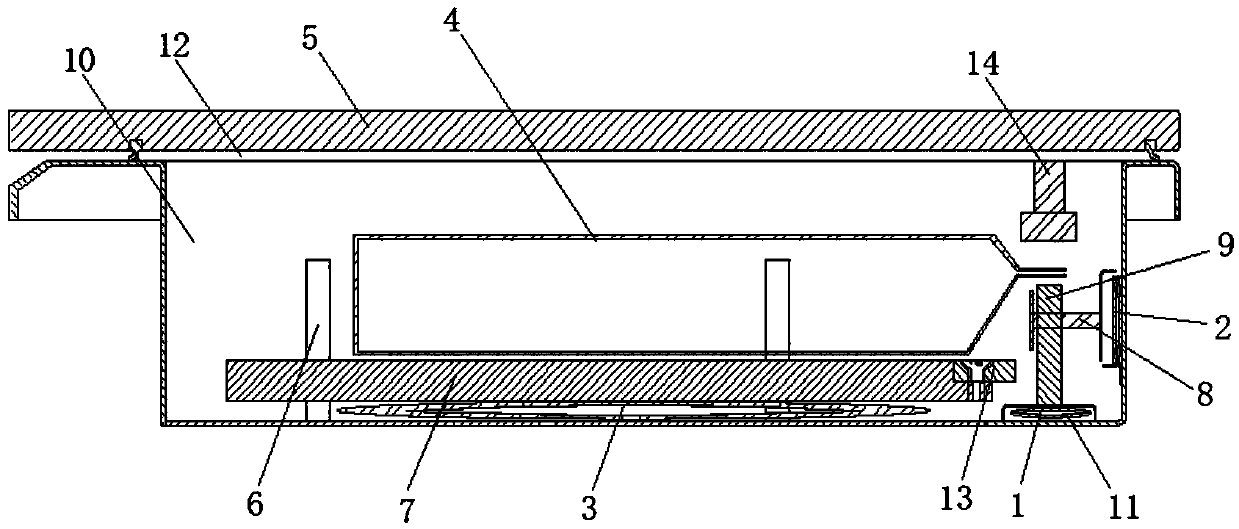

[0037] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

[0038] like figure 1 As shown, the particle shaping vacuum packaging machine provided in this embodiment includes a packaging body with a vacuum chamber 10; a packaging bag 4 is placed in the vacuum chamber 10, and a packaging bag 4 is provided in the packaging body. A plurality of airbags for vacuum packaging, the vacuum chamber 10 completes the vacuum extraction through the electromagnetic valve and the vacuum pump arranged in the packaging body; after the vacuum extraction of the packaging bag 4 is completed by the vacuum pump, it is sealed by a sealing device, after sealing The packaging bag 4 is moved by a moving device, and the vacuum-extracted and packaged p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com