Micropore plate washing machine

A technology of micro-orifice plate and plate washing machine, which is applied to the stacking, transportation and packaging of objects, cleaning methods and utensils, etc., which can solve the problems of poor transmission accuracy, low cost, and plate not in place, and achieve the goal of improving reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

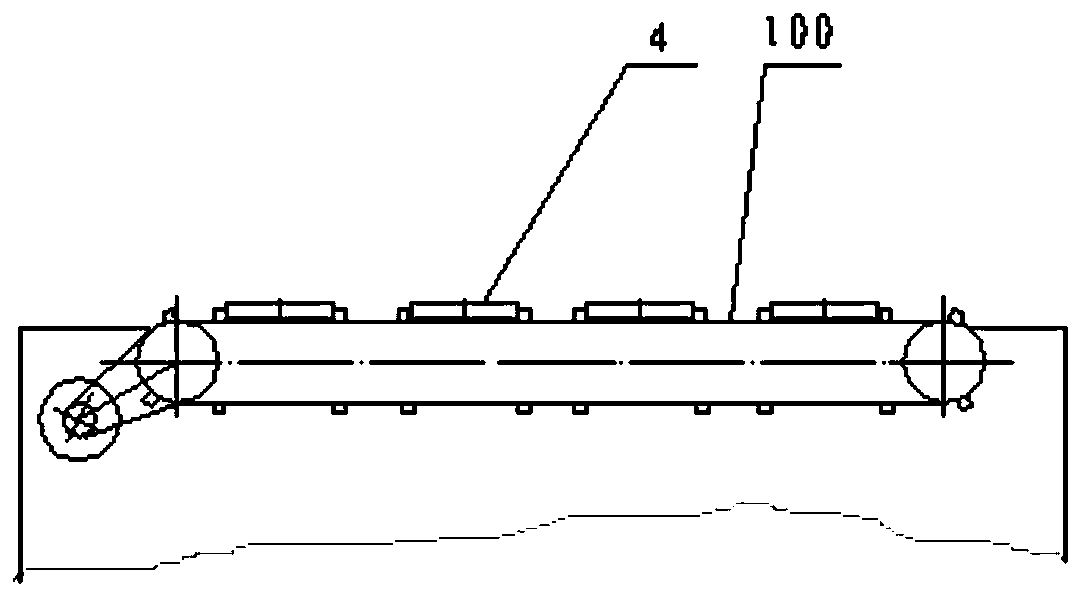

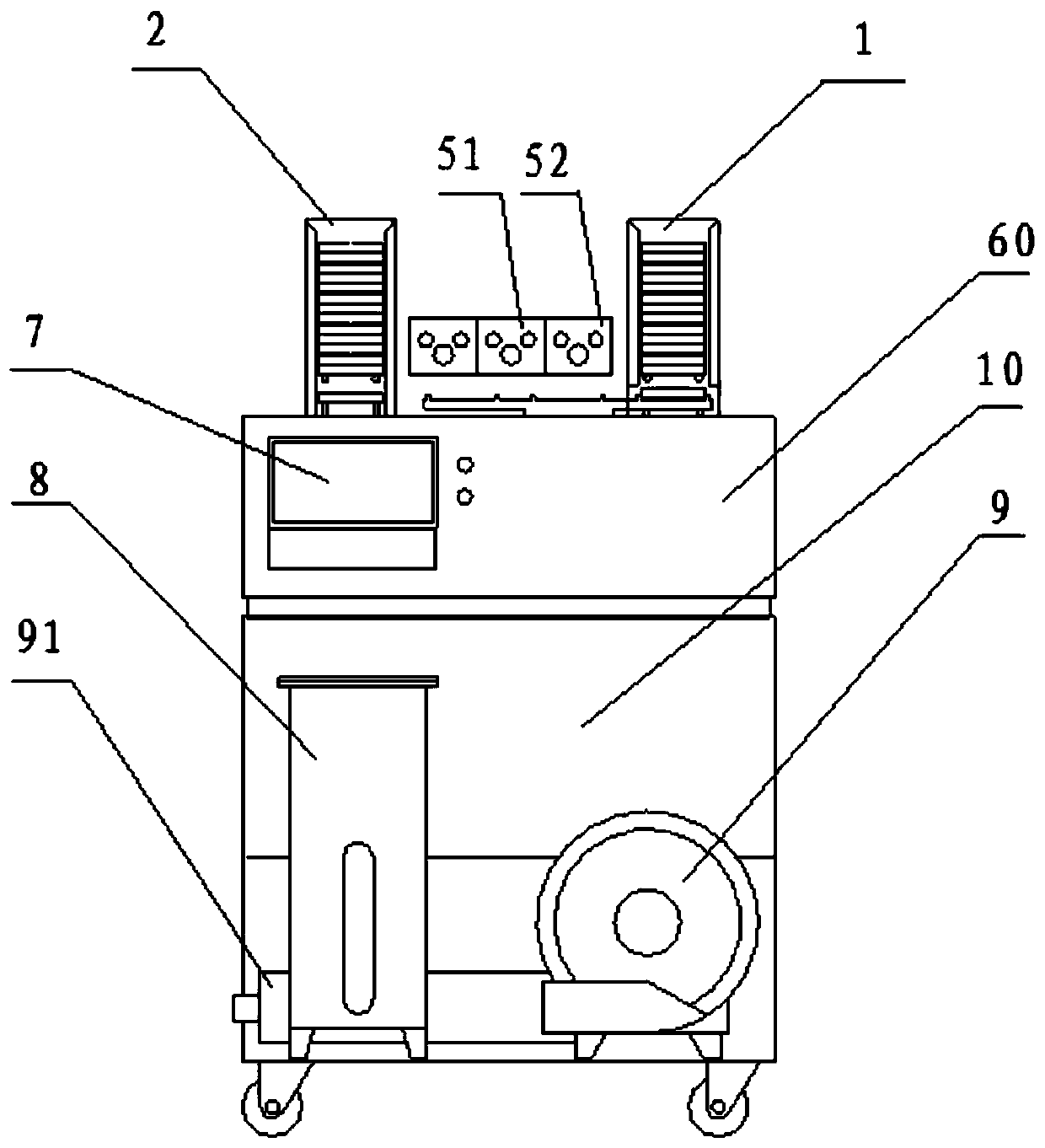

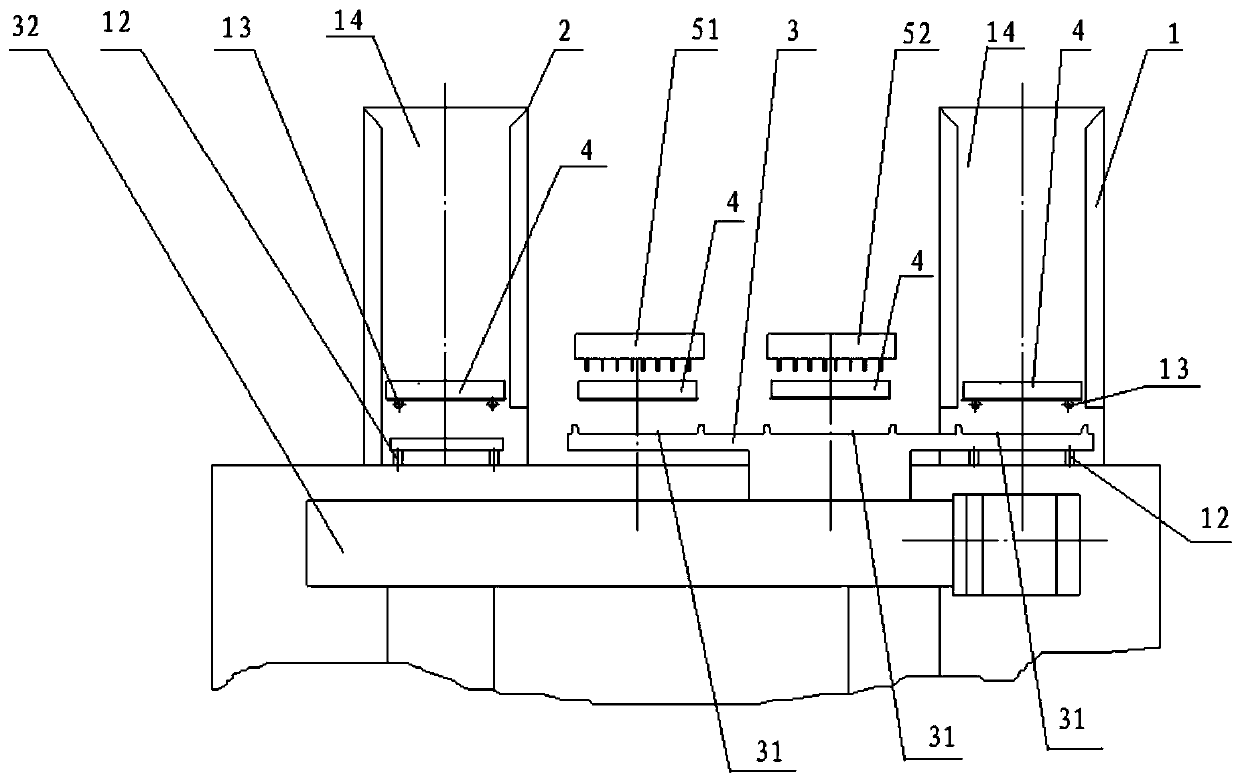

[0045] like Figure 1-10 As shown, a microplate washing machine includes a frame 60, a microplate moving device and a microplate processing device, and the microplate moving device includes a first device 1, a second device 2, and a moving tray 3 And the transfer plate device 6 corresponding to the microplate processing device, the first device 1 and the second device 2 are respectively installed on the upper side of the frame 60 and are used for stacking and storing the microplate 4, the moving The tray 3 is movably arranged between the first device 1 and the second device 2 for transferring the microplate 4 between the first device and the second device, and the transfer plate The device 6 is mounted on the rack 60 for transferring the microplate 4 between the mobile tray 3 and the microplate processing device.

[0046] The beneficial effects of this embodiment are: the movement of the micro-orifice plate 4 is realized by the micro-orifice plate shifting device, and the pur...

Embodiment 2

[0048] like Figure 1-10 As shown, a microplate washing machine includes a frame 60, a microplate moving device and a microplate processing device, and the microplate moving device includes a first device 1, a second device 2, and a moving tray 3 And the transfer plate device 6 corresponding to the microplate processing device, the first device 1 and the second device 2 are respectively installed on the upper side of the frame 60 and are used for stacking and storing the microplate 4, the moving The tray 3 is movably arranged between the first device 1 and the second device 2 for transferring the microplate 4 between the first device and the second device, and the transfer plate The device 6 is mounted on the rack 60 for transferring the microplate 4 between the mobile tray 3 and the microplate processing device.

[0049] The movement of the microporous plate 4 is realized by the microporous plate moving device, and the purpose of moving the microporous plates in the first de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com