Reactive polyurethane hot melt adhesive for PVC and preparation method thereof

A polyurethane hot-melt adhesive and reactive technology, applied in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve problems such as bonding failure, large climate impact, and inability to avoid sudden climates. Achieve the effect of mild conditions and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The present invention also provides a preparation method of the reactive polyurethane hot-melt adhesive for PVC described in the above technical solution, comprising the following steps:

[0053] Mix low hydroxyl value crystalline polyester polyols, polyether polyols, amorphous polyester polyols, liquid polyester polyols, antioxidants, and tackifying resins for dehydration, then add isocyanate for reaction, and finally add adhesion promoters The agent and catalyst are vacuum defoamed, and the reactive polyurethane hot melt adhesive is obtained after uniform dispersion.

[0054] The present invention firstly mixes low hydroxyl value crystalline polyester polyols, polyether polyols, amorphous polyester polyols, liquid polyester polyols, antioxidants, and tackifying resins; the mixing process is preferably specifically:

[0055] Add low hydroxyl value crystalline polyester polyol, liquid polyester polyol, amorphous polyester polyol, and antioxidant into the reaction kettle...

Embodiment 1

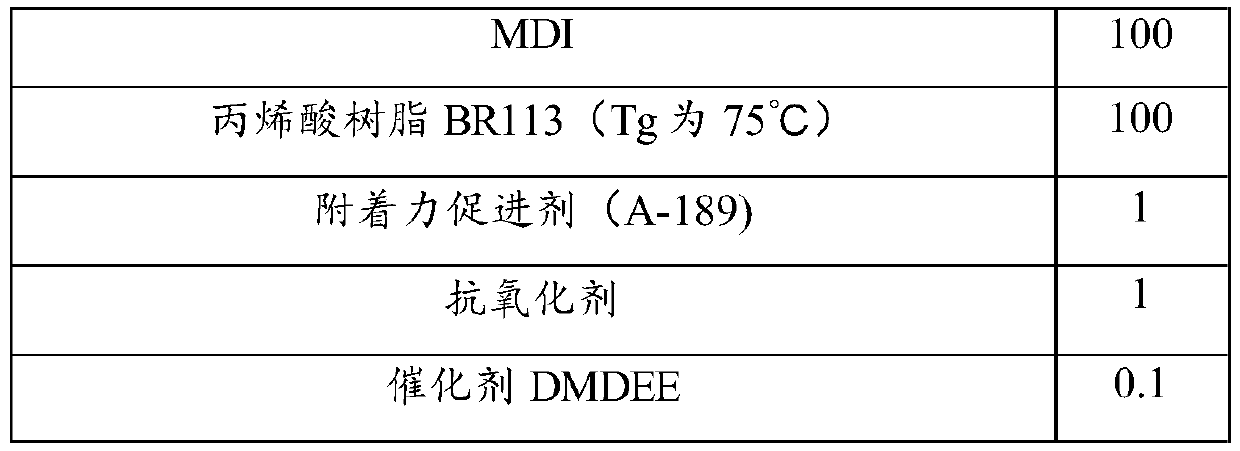

[0069] The formula quantity of the raw materials used in Example 1 is shown in Table 1.

[0070] The formula quantity of raw material used in table 1 embodiment 1

[0071]

[0072]

[0073] Add low hydroxyl value crystalline polyester polyol, liquid polyester polyol, amorphous polyester polyol, and antioxidant into the reaction kettle according to the formula amount, raise the temperature to 80°C, add the formula amount of tackifying resin, and heat up to 105℃~130℃, dehydrate for 2 hours under the condition of vacuum degree ≤-0.095MPa, cool down to 90℃ after water content ≤500ppm, add the formula amount of isocyanate, heat up to 130℃, react for 45min, add the formula after the reaction is complete A certain amount of adhesion promoter and catalyst, vacuum defoaming for 0.5h, after stirring and dispersing evenly, it can be glued and filled to obtain a reactive polyurethane hot melt adhesive for PVC.

Embodiment 2

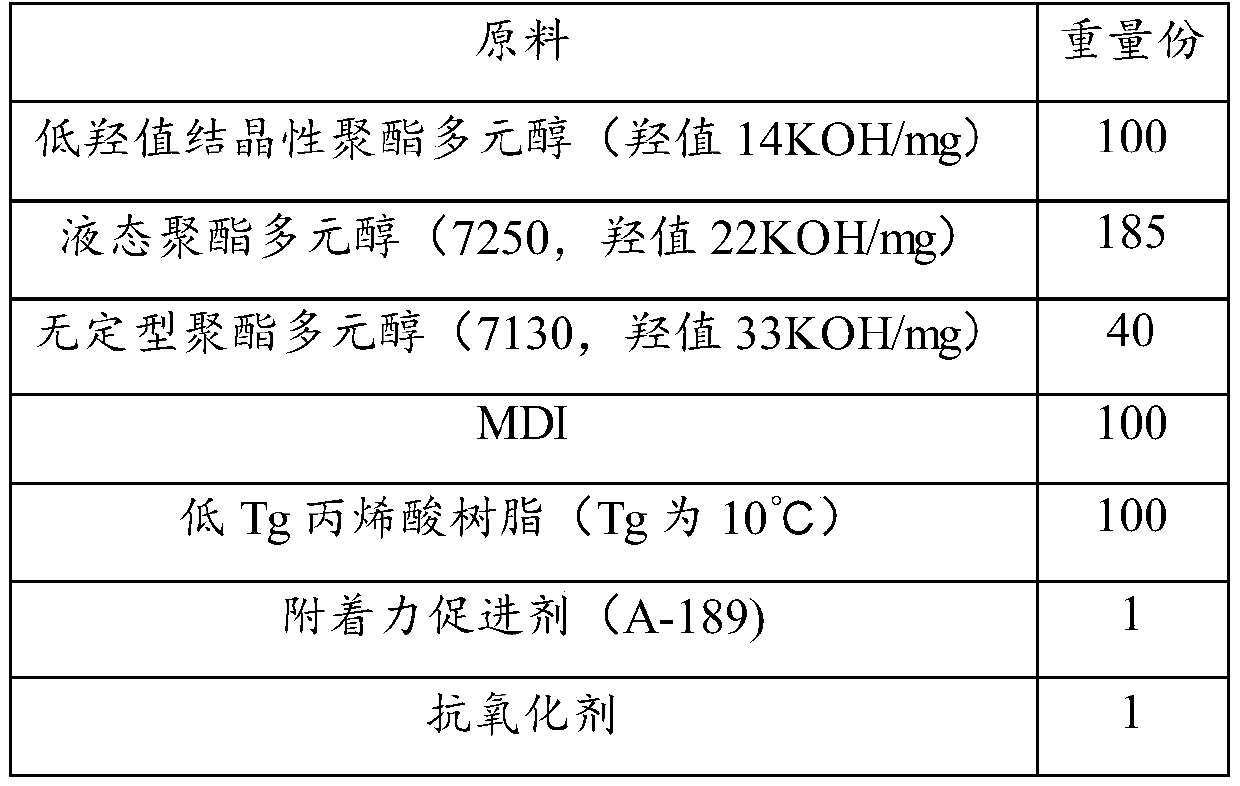

[0075] The formulation amount of the raw materials used in Example 2 is shown in Table 2.

[0076] Table 2 The formula quantity of raw material used in embodiment 2

[0077] raw material

[0078] Add low hydroxyl value crystalline polyester polyol, liquid polyester polyol, amorphous polyester polyol, and antioxidant into the reaction kettle according to the formula amount, raise the temperature to 80°C, add the formula amount of tackifying resin, and heat up to 105℃~130℃, dehydrate for 2 hours under the condition of vacuum degree ≤-0.095MPa, cool down to 90℃ after water content ≤500ppm, add the formula amount of isocyanate, heat up to 130℃, react for 45min, add the formula after the reaction is complete A certain amount of adhesion promoter and catalyst, vacuum defoaming for 0.5h, after stirring and dispersing evenly, it can be glued and filled to obtain a reactive polyurethane hot melt adhesive for PVC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com