Anti-sedimentation magnetorheological damper based on online monitoring

A magnetorheological damper and anti-settling technology, applied in shock absorbers, shock absorbers, springs/shock absorbers, etc. subsidence effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

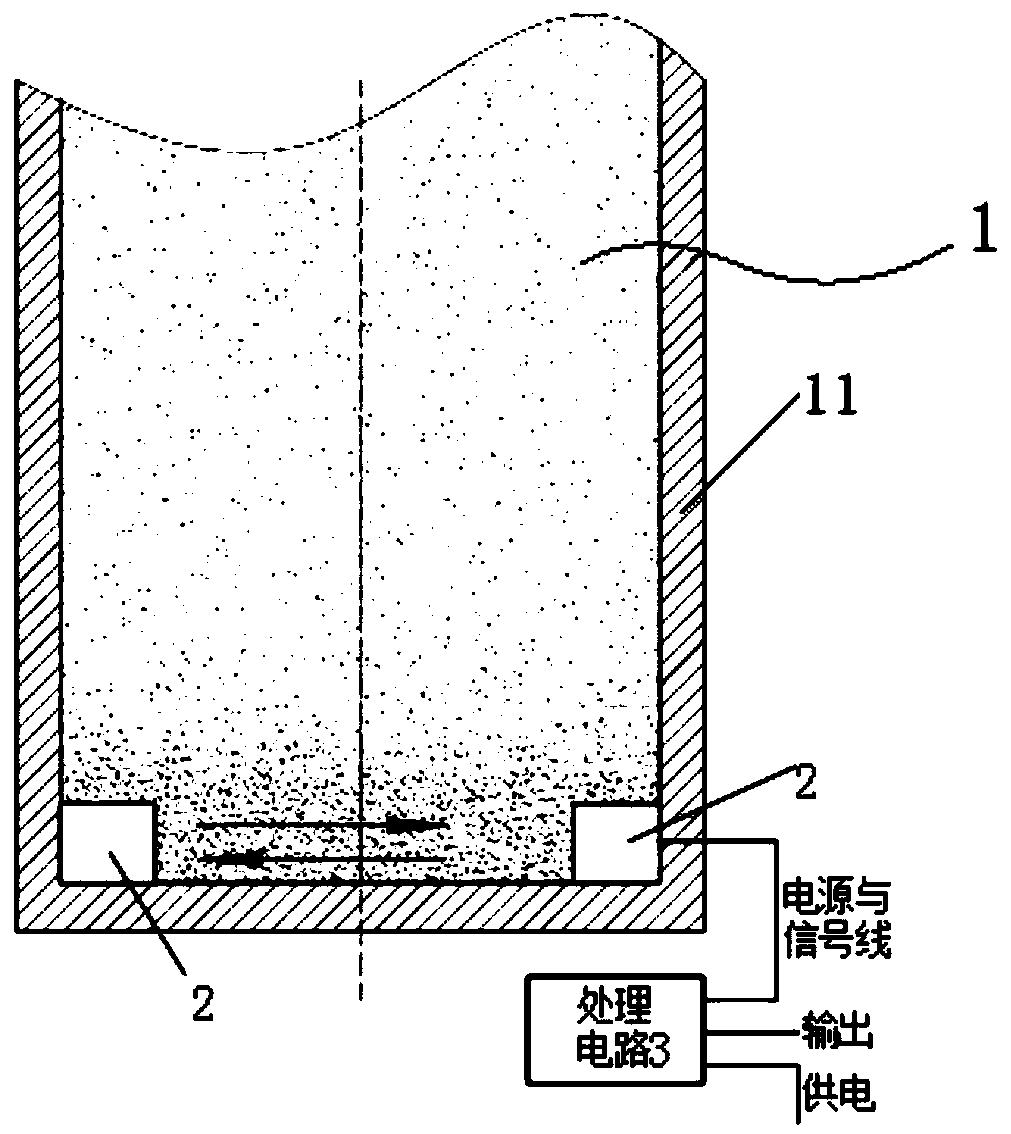

[0043] see figure 1 and figure 2 , an anti-settling magnetorheological damper based on online monitoring, mainly includes a magnetorheological damper 1, an ultrasonic transducer 2 and a processing circuit 3.

[0044] The magneto-rheological damper 1 includes a working cylinder 11 and a motor for realizing dispersion of the magneto-rheological fluid. Magnetorheological fluid is housed in the working cylinder 11 .

[0045] The magnetorheological damper 1 drives the motor to disperse the magnetorheological fluid after receiving the electrical excitation signal from the processing circuit 3 .

[0046] The ultrasonic transducer 2 is attached to the side wall at the bottom of the working cylinder 11 .

[0047] The wiring harness 21 of the ultrasonic transducer 2 extends out of the magneto-rheological damper 1 and is connected to the processing circuit 3 .

[0048] The magnetorheological fluid settles at the bottom of the cylinder so that the dispersed phase has the highest volu...

Embodiment 2

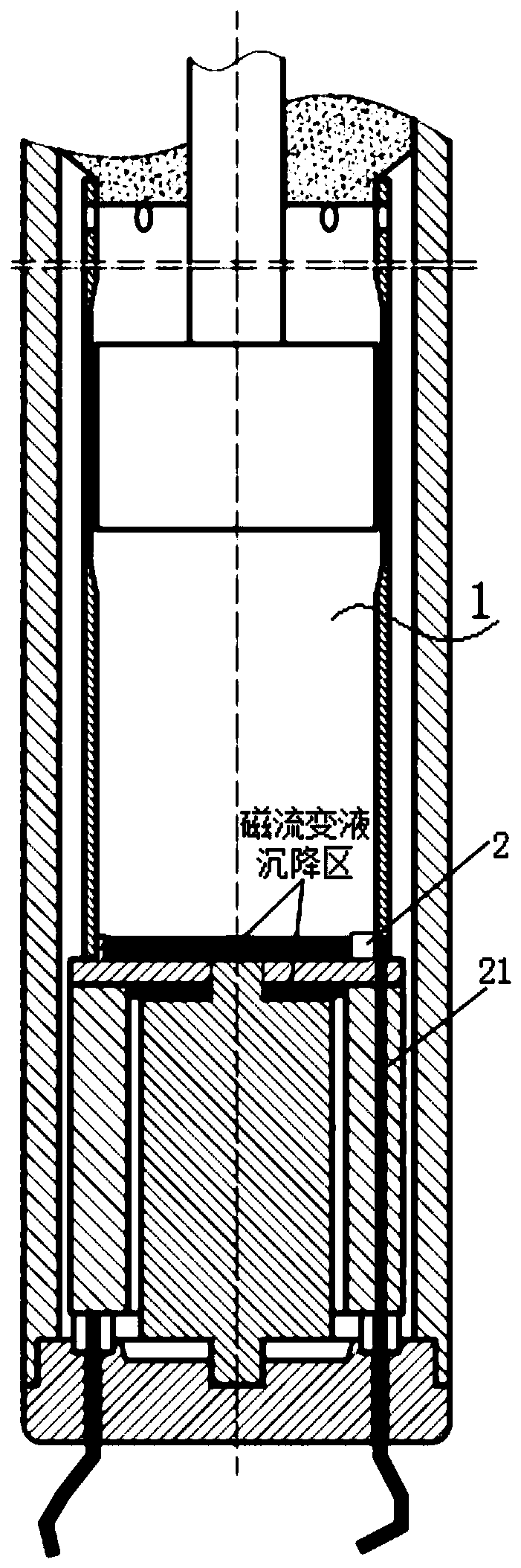

[0073] see Figure 6 to Figure 11 , The magnetorheological damper 1 mainly includes a working cylinder 11, a liquid cylinder 12, a bottom cover 13, a top cover 17, a piston assembly 18, a piston rod 19 and a motor. The motor includes a positioning column 14 , a rotor 15 and a stator 16 .

[0074] The liquid cylinder 12 is a hollow cylinder, and the opening at its lower end has threads.

[0075] The liquid cylinder 12 and the bottom cover 13 are sealed by an O-ring.

[0076] The upper end of the bottom cover 13 is a ring I131. The outer wall of the ring I131 has threads. The lower end of the bottom cover 13 is a disk I132. A circular hole I1321 is formed at the center of the end surface of the disc I132. The end surface of the disc I132 is provided with several counterbore holes 1322 on the same circumference.

[0077] The upper end of the bottom cover 13 is installed at the opening of the lower end of the liquid cylinder 12 .

[0078] The positioning column 14 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com