Composite rigid reinforced bulletproof helmet

A bulletproof helmet and composite rigidity technology, which is applied in protective equipment, offensive equipment, personnel protection equipment, etc., can solve the problems of large overall deformation, high temperature creep, affecting the service life and safety of the helmet, so as to avoid impact damage, Improved impact resistance, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

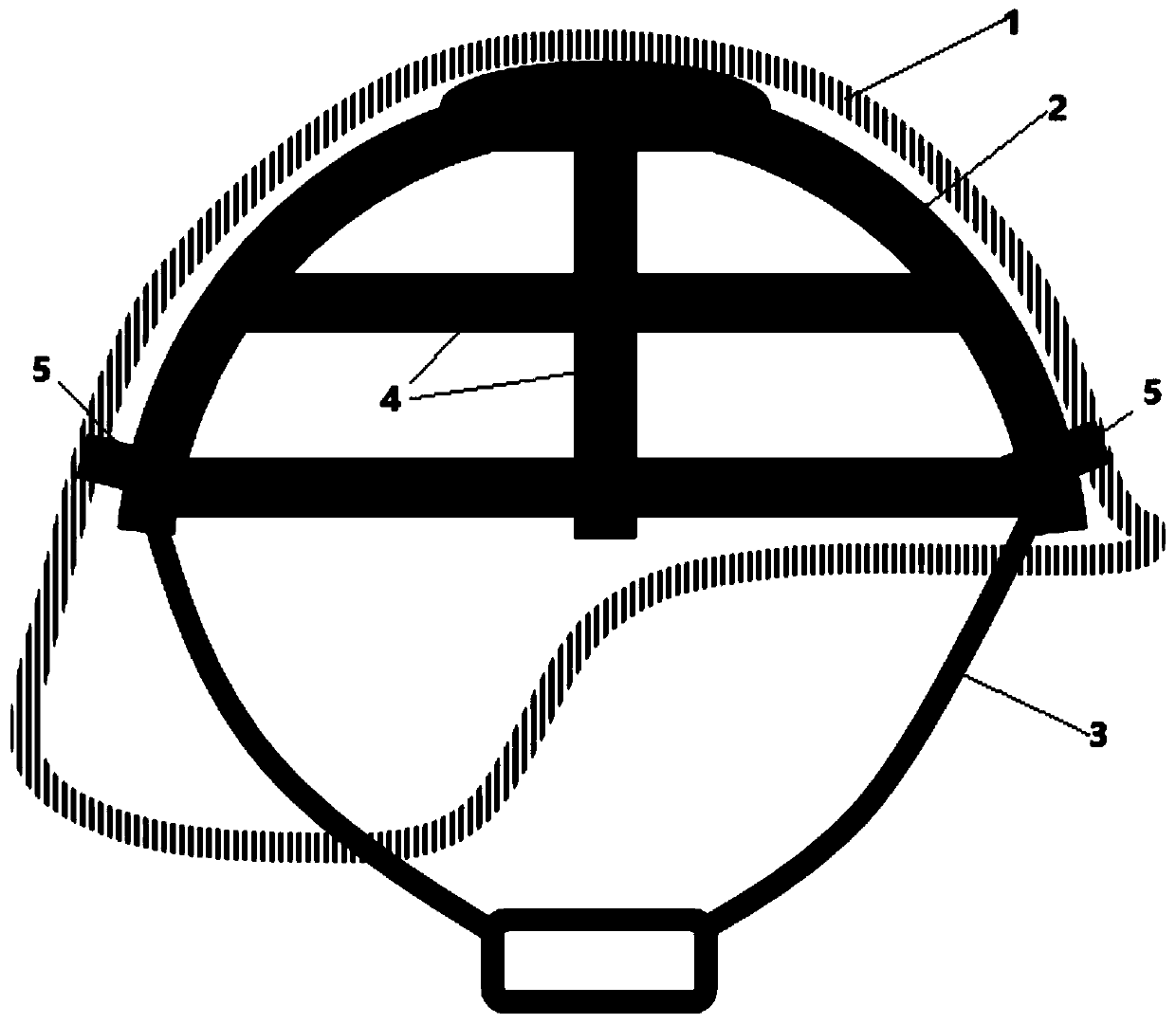

[0032] A kind of composite rigidity reinforced bulletproof helmet (reference figure 1 ), which includes: a bulletproof helmet shell 1, a composite rigid reinforced inner liner 2, a suspension system 3 and a reinforcing rib 4, and the composite rigid reinforced inner liner 2 is fixed on the inner surface of the bulletproof helmet shell; the suspension system 3 is fixed on the edge of the composite rigid reinforced inner liner 2; the bulletproof helmet shell 1 is formed by compounding fiber and thermoplastic resin; the composite rigid reinforced inner liner 2 is formed by compounding carbon fiber and thermosetting resin matrix, and the composite The rigid reinforced inner lining layer 2 has a hollow mesh structure; the reinforcing ribs 4 are fixed on the surface of the composite rigid reinforced inner lining layer 2 through bolts 5 .

[0033]The bulletproof helmet shell 1 is laminated by the unidirectional prepreg fabric of UHMWPE fiber impregnated with polyurethane, and the lam...

Embodiment 2

[0036] A composite rigid reinforced bulletproof helmet, and the structure and connection relationship are the same as embodiment 1, the difference is:

[0037] (1) The bulletproof helmet shell 1 is laminated by an orthogonal prepreg fabric impregnated with aramid fiber polyolefin resin, and the laminated prepreg fabric is pressed at 130 ° C and 20 MPa for 30 minutes. Forming a bulletproof helmet shell 1 with a thickness of 6 mm.

[0038] (2) The composite rigid reinforced inner lining layer 2 is made of a composite material formed by unidirectional fabric cross-laminated T1000 carbon fiber impregnated with phenolic resin, and its thickness is 5 mm. The composite rigid reinforced inner lining layer 2 is vacuum-assisted. It is embedded in the inner surface of the bulletproof helmet shell, and the composite rigid reinforced inner liner 2 and the bulletproof helmet shell 1 are formed as a whole by means of bonding.

Embodiment 3

[0040] A composite rigid reinforced bulletproof helmet, and the structure and connection relationship are the same as embodiment 1, the difference is:

[0041] (1) The bulletproof helmet shell 1 is laminated by unidirectional prepreg fabric impregnated with PBO fiber polyethylene resin emulsion, and the laminated prepreg fabric is pressed at 140 ° C and 21 MPa for 35 minutes. Forming a bulletproof helmet shell 1 with a thickness of 5.5mm.

[0042] (2) The composite rigid reinforced inner liner 2 is made of a composite material formed of two-dimensionally woven cross-laminated T700 carbon fibers impregnated with unsaturated polyester resin, and its thickness is 4 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com