Method for detecting surface contamination of silicon wafer

A silicon wafer surface and detection method technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problem that it is impossible to determine what kind of substance the silicon wafer pollutants are

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A method for detecting contamination on the surface of a polysilicon wafer, comprising the steps of:

[0055] 1. Adhere the polysilicon wafer sample on the sample stage, and then put the polysilicon wafer sample together with the sample stage into the sample chamber of the scanning electron microscope, and evacuate to 2.0×10 -5 mbar, then adjust the electron beam acceleration voltage to 5kV, and the magnification is 1250 times, scan the contaminated area on the surface of the polysilicon wafer sample, and obtain the microscopic image of the contaminated area, see figure 1 .

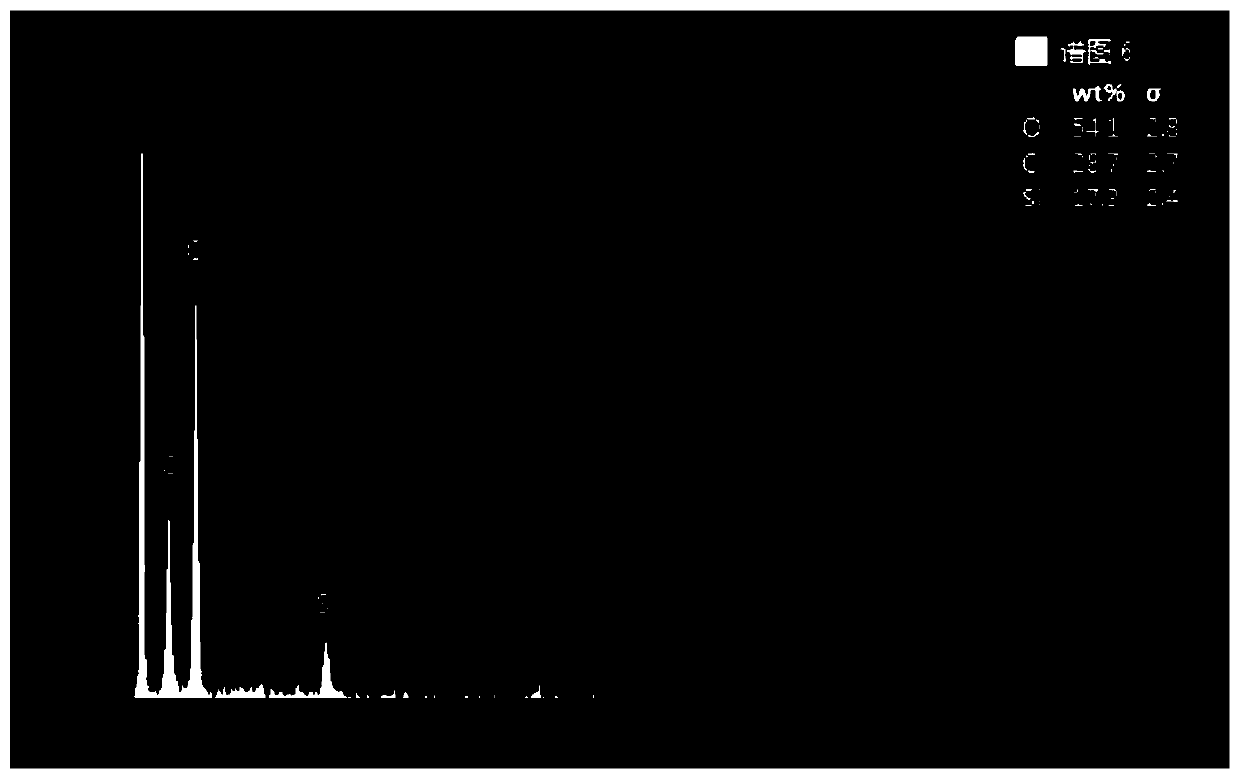

[0056] 2. Adjust the electron beam acceleration voltage to 20kV, and the X-ray energy spectrum analyzer collects the X-ray energy spectrum signals of the contaminated area, and confirms that the contaminated area contains three elements, C, O and Si, see figure 2 .

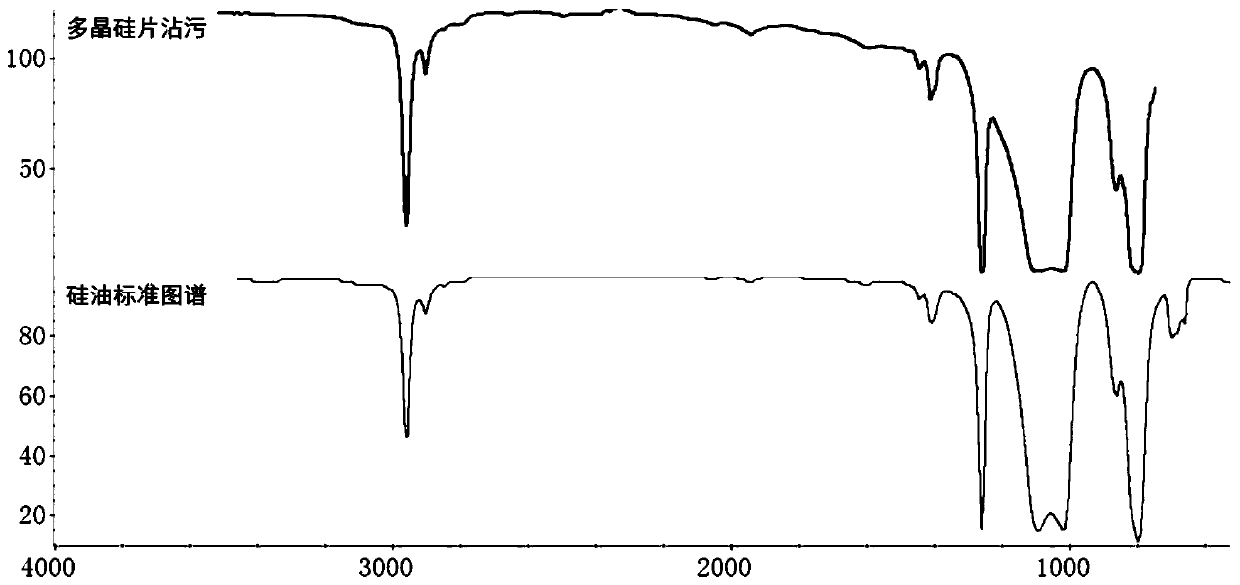

[0057] 3. Transfer the polysilicon wafer sample to the stage of the micro-infrared spectrometer, and collect the micro-infrared sp...

Embodiment 2

[0060] A method for detecting contamination on the surface of a single crystal silicon wafer, comprising the steps of:

[0061] 1. Adhere the monocrystalline silicon wafer sample on the sample stage, and then put the monocrystalline silicon wafer sample together with the sample stage into the sample chamber of the scanning electron microscope, and evacuate to 2.0×10 -5 mbar, then adjust the electron beam acceleration voltage to 5kV, and the magnification is 200 times, scan the contaminated area on the surface of the single crystal silicon wafer sample, and obtain the microscopic image of the single crystal contaminated area.

[0062] 2. Adjust the electron beam acceleration voltage to 20kV, and the X-ray energy spectrum analyzer collects the X-ray energy spectrum signal of the contaminated area, and confirms that the contaminated area contains two elements, C and O.

[0063] 3. Transfer the single crystal silicon wafer sample to the stage of the micro-infrared spectrometer, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com