Amorphous nanocrystalline special-shaped magnetic core-based direct current type current sensor

An amorphous nanocrystalline, current sensor technology, applied in voltage/current isolation, measuring current/voltage, instruments, etc., can solve the problems of poor linearity, temperature stability, affecting sensor measurement accuracy, etc., to avoid distribution Non-uniformity, good linearity of magnetic flux density and current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

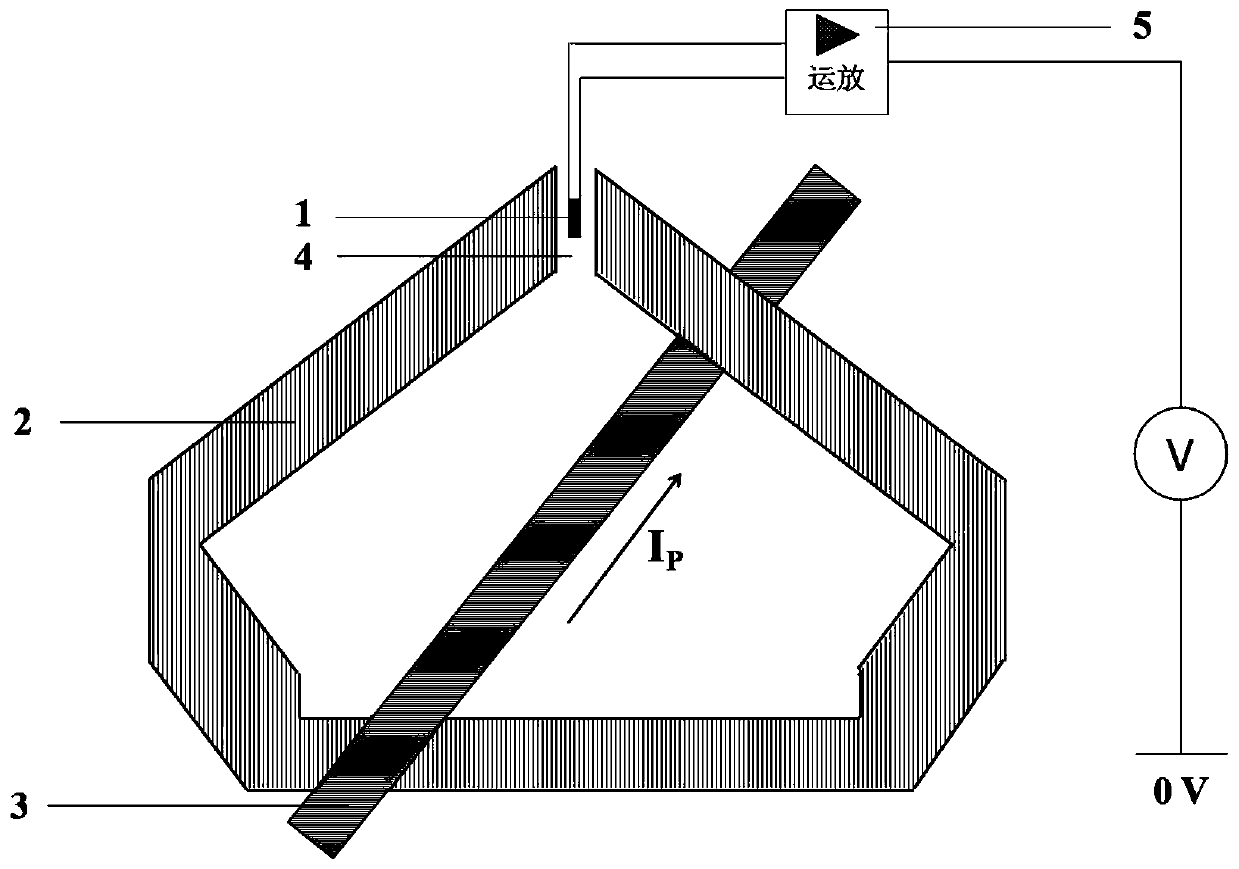

[0032] like figure 1 As shown, a direct-amplification current sensor based on an iron-based amorphous shaped magnetic core, the sensor includes a Hall element 1, a triangular shaped shaped magnetic core 2, a conductor 3, a magnetic core opening air gap 4 and a signal output device 5. The Hall element 1 is located at the center of the air gap 2 of the magnetic core opening, and the Hall element 1 is connected with the signal output device 5 . The conductor 3 is located at the very center of the window of the triangular shaped magnetic core 2 .

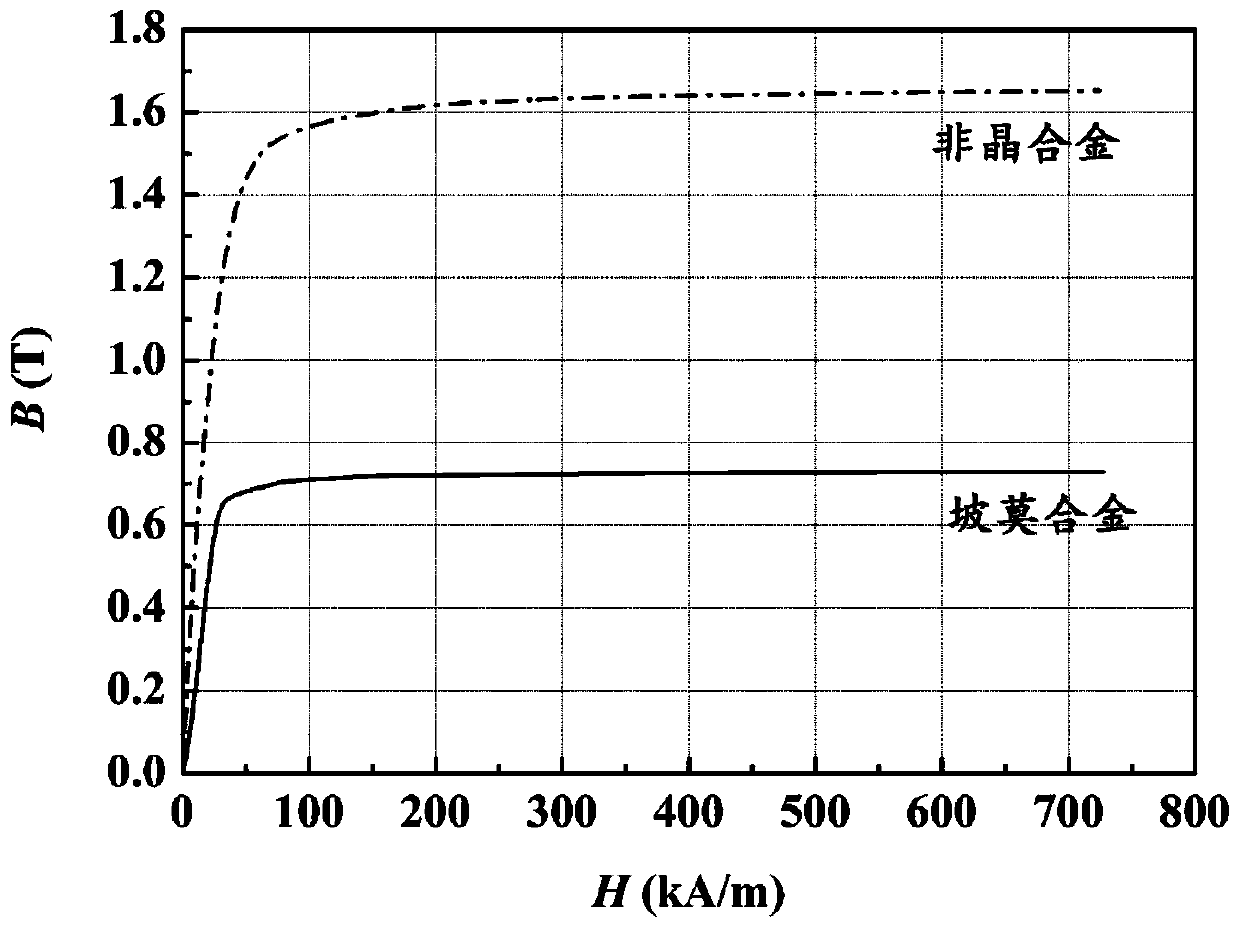

[0033] The triangular special-shaped magnetic core 2 is cut from the iron-based amorphous broadband with low coercive force and high saturation magnetic induction according to the special-shaped structure; in order to protect the integrity of the iron-based amorphous special-shaped magnetic core For contact, the triangular shaped magnetic core 2 is formed by bonding layer by layer of adhesive, and the surface of the triangular shaped m...

Embodiment 2

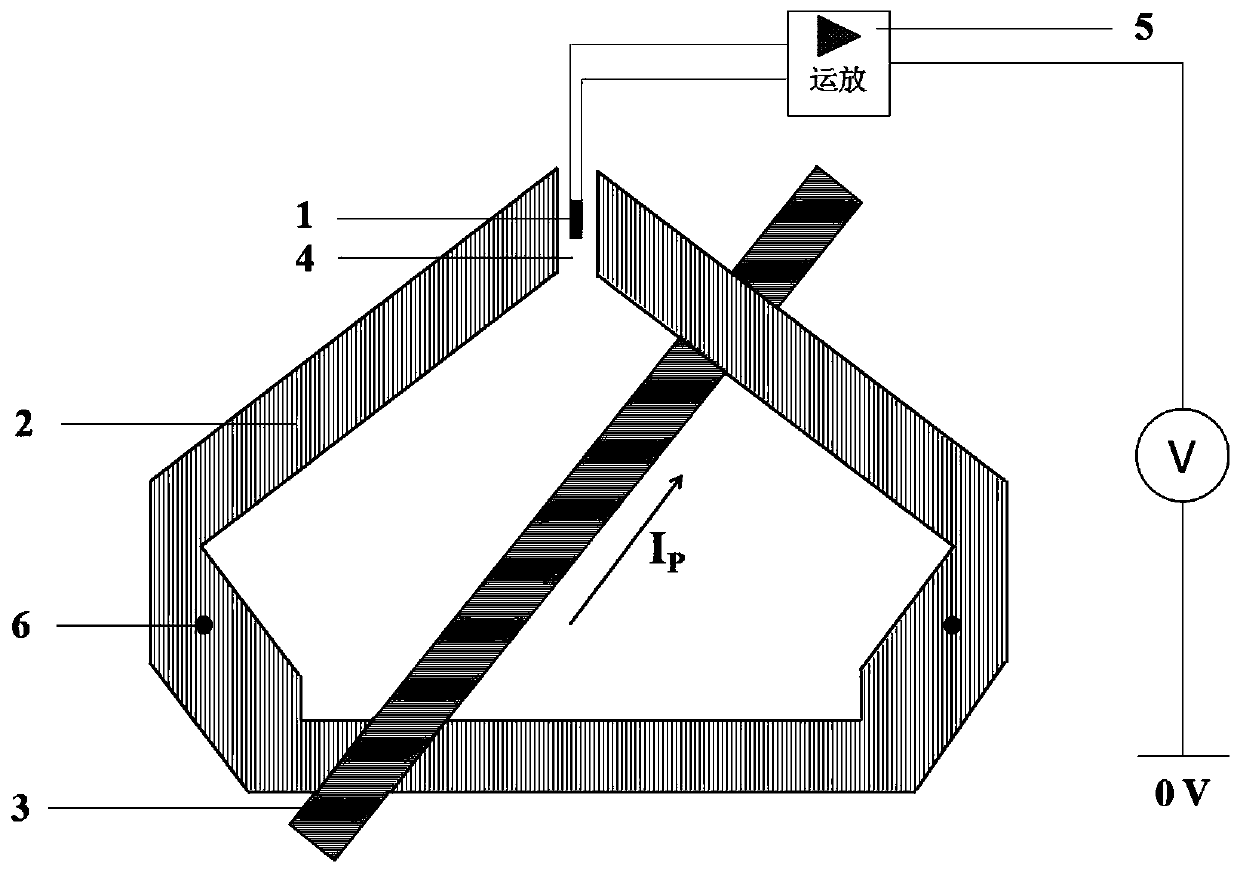

[0041] Such as Figure 5 As shown, the present embodiment provides a direct discharge current sensor based on iron-based nanocrystalline special-shaped magnetic core, the structure of which is basically the same as that of the direct discharge current sensor in Embodiment 1. The special-shaped magnetic core 2 is an iron-based nanocrystalline broadband material; (2) In this embodiment, the number of open air gaps 4 of the triangular special-shaped magnetic core is two. The soft magnetic performance of the iron-based nanocrystalline broadband of this implementation is better than that of iron-based amorphous nanocrystalline soft magnetic materials, and the increase of the number of air gaps can improve the maximum working linear input current, so the direct current sensor of this embodiment improves The measurement range and accuracy of the sensor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com