Advanced packaging structure for graphene-based IPM (Intelligent Power Module) module, and processing technology

A graphene-based, packaging structure technology, applied in the direction of semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve the problems of IPM electrical, mechanical, corrosion, high power density, module failure, etc., to improve the use of Longevity, efficient heat dissipation, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

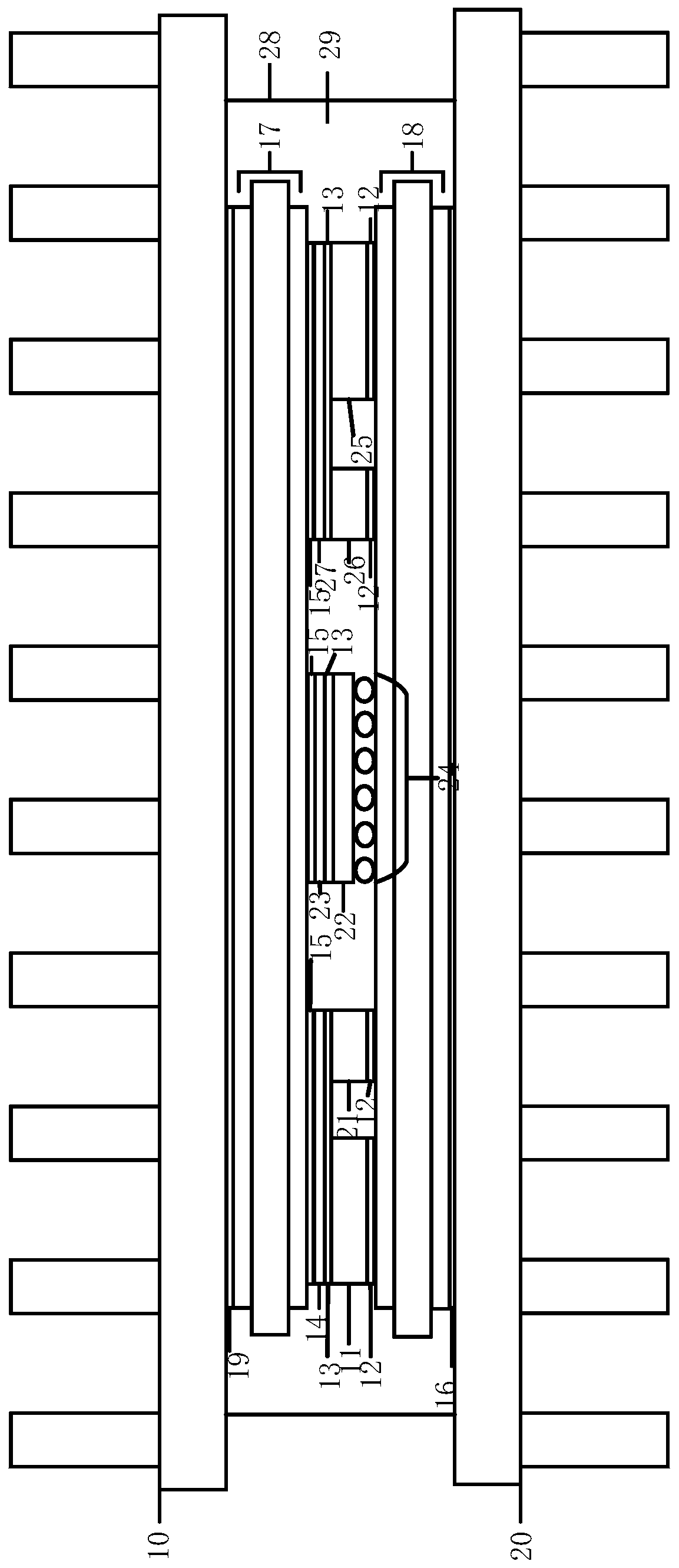

[0042] The present invention will be further described below in conjunction with drawings and embodiments.

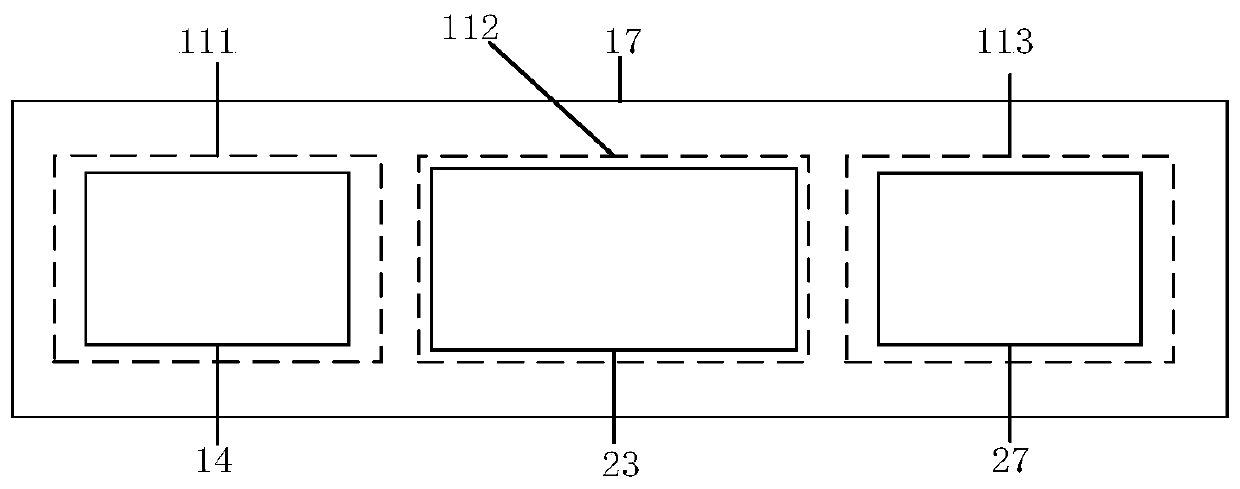

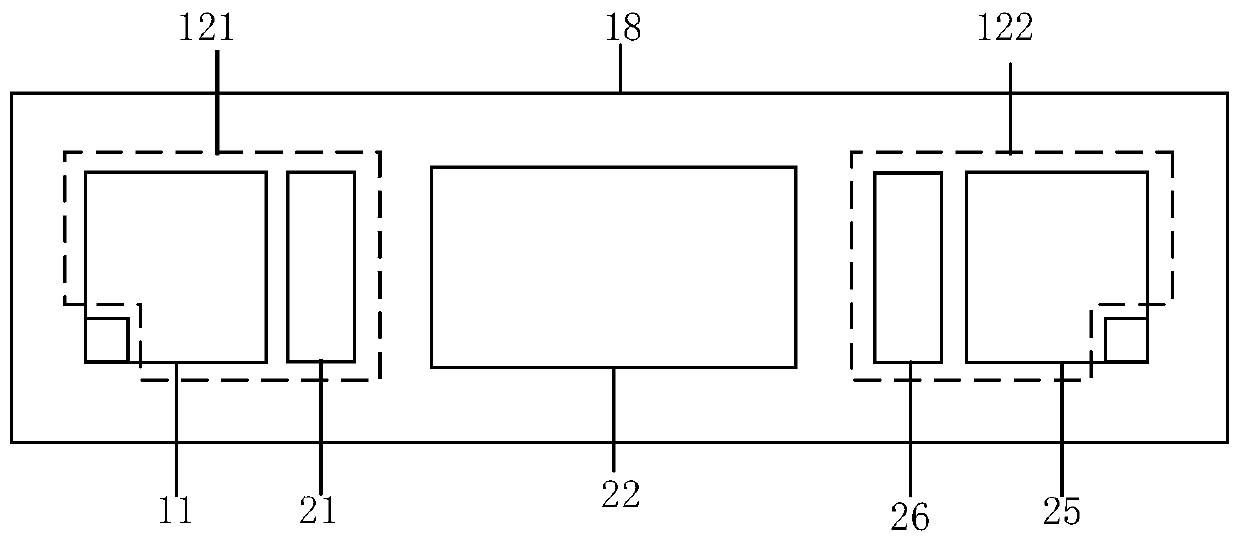

[0043] The present invention proposes an advanced packaging structure of a graphene-based IPM module, which generally includes an IGBT chip, a fast recovery diode (Fast Recovery Diode, FRD) chip, a driver chip, and a graphene-based DBC liner (ie, a graphene-based copper-clad ceramic substrate) , buffer pads, solder layers, solder balls, plastic enclosures, packaging resins, thermal grease, and heat sinks. Wherein, the upper graphene-based DBC liner 17 is obtained by mounting the graphene-based film prepared by the redox method in the graphene application area designed on the surface of the upper copper layer of a copper-clad ceramic substrate, and the lower graphene-based DBC liner 18 is obtained. It is obtained by growing a graphene film by chemical vapor deposition in the graphene application area designed on the surface of the upper copper layer of another copper-cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com