Composite separator and lithium ion battery containing the same

A technology of lithium-ion batteries and composite diaphragms, which is applied to secondary batteries, battery pack components, circuits, etc., can solve the problems of battery shipment safety hazards, high self-discharge rate, poor battery consistency, etc., to improve work efficiency and The effect of good product accuracy, high tensile and puncture strength, and large closed-cell melting temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

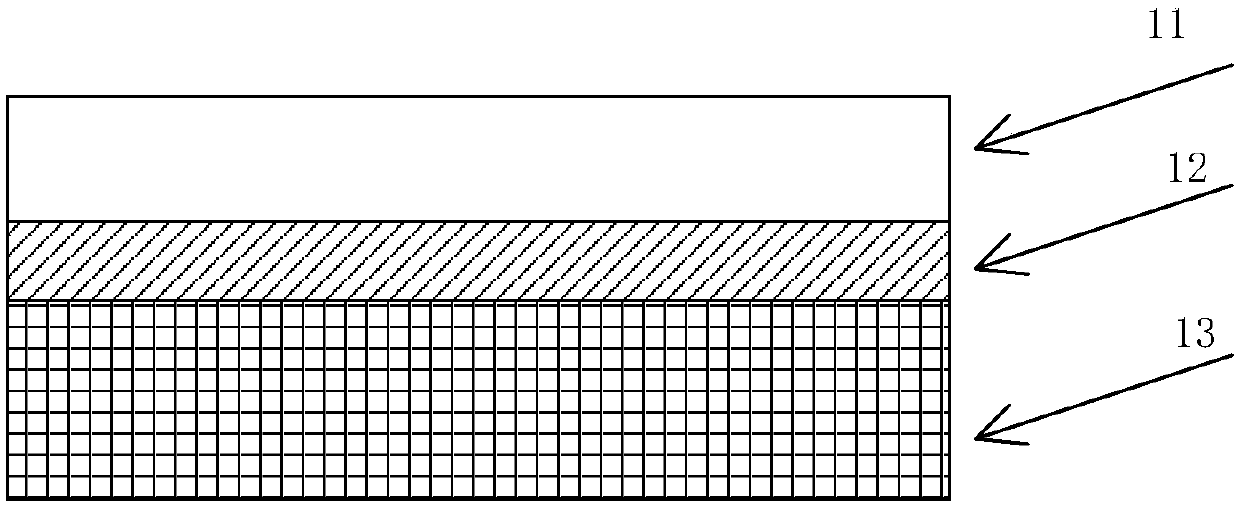

[0035] figure 1 It is a schematic structural diagram of the lithium-ion battery composite separator in Example 1, wherein 11 is the first polyolefin base film, 12 is the first inorganic particle layer and 13 is the non-woven fabric base film. The material of the first polyolefin base film is PE, the thickness is 12 μm, the porosity is 40%, and the pore diameter is 0.04 μm; the material of the first inorganic particle layer is aluminum oxide, and the thickness is 10 μm; the material of the non-woven fabric base film It is PET with a thickness of 15 μm, a porosity of 50%, and a pore size of 1 μm.

[0036] A lithium-ion battery containing the above-mentioned composite diaphragm, comprising a square aluminum case and a positive electrode sheet, a negative electrode sheet, a composite diaphragm and an electrolyte disposed in the aluminum case; the positive electrode material is a ternary material, and the negative electrode material is Graphite, the electrolyte is an organic solve...

Embodiment 2

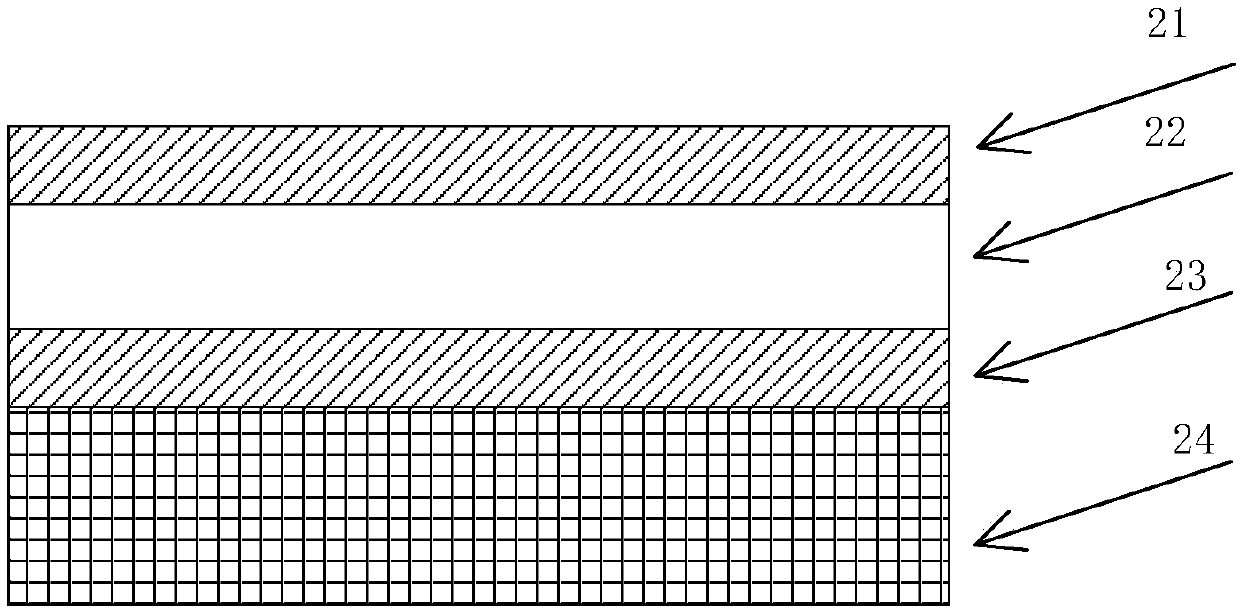

[0038] figure 2 It is a structural schematic diagram of the lithium-ion battery composite separator of Example 2, wherein 21 is the first inorganic particle layer, 22 is the first polyolefin base film, 23 is the second inorganic particle layer and 24 is the non-woven fabric base film. The material of the first polyolefin base film is PP, the thickness is 16 μm, the porosity is 30%, and the pore diameter is 0.06 μm; the material of the first and second inorganic particle layers is titanium dioxide, and the thickness is 1 μm; the material of the non-woven fabric base film It is PI, the thickness is 10 μm, the porosity is 60%, and the pore size is 2 μm.

[0039] A lithium-ion battery containing the above-mentioned composite separator, comprising a square plastic casing and a positive electrode sheet, a negative electrode sheet, a composite separator and an electrolyte disposed in the plastic casing; the positive electrode material is a ternary material, and the negative electrod...

Embodiment 3

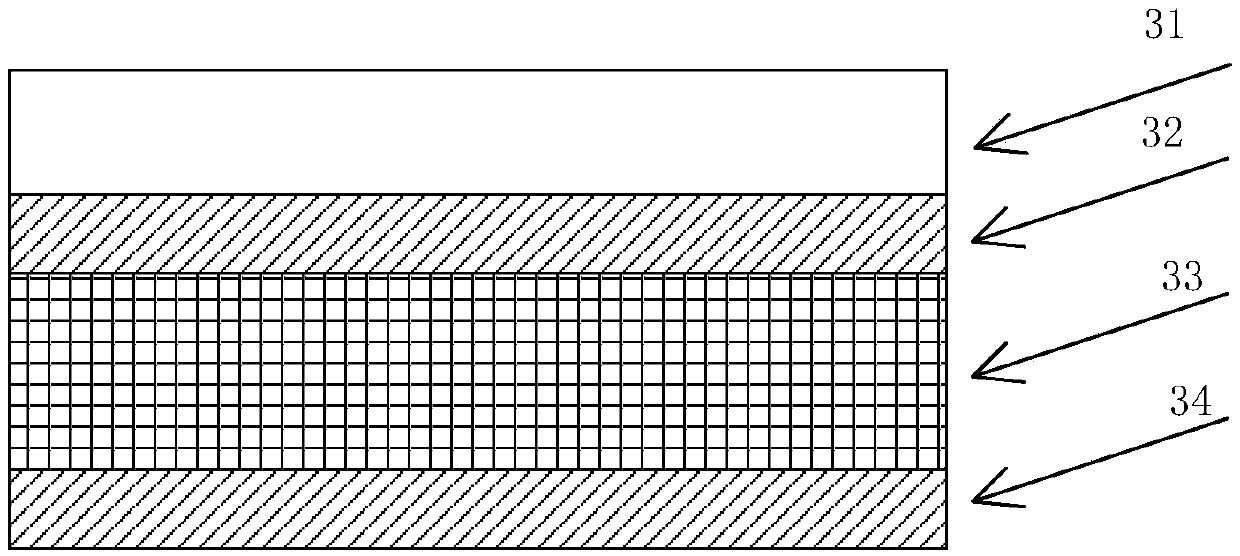

[0041] image 3 It is a schematic structural diagram of the lithium-ion battery composite separator of Example 3, wherein 31 is the first polyolefin base film, 32 is the first inorganic particle layer, 33 is the non-woven fabric base film and 34 is the second inorganic particle layer. The material of the first polyolefin base film is PE, the thickness is 10 μm, the porosity is 50%, and the pore diameter is 0.03 μm; the material of the first and second inorganic particle layers is zirconia, and the thickness is 5 μm; the non-woven fabric base film The material is aramid fiber, the thickness is 20 μm, the porosity is 30%, and the pore diameter is 10 μm.

[0042] A lithium-ion battery containing the above-mentioned composite diaphragm, comprising a square aluminum-plastic film and a positive electrode sheet, a negative electrode sheet, a composite diaphragm and an electrolyte disposed in the aluminum-plastic film; the positive electrode material is a ternary material, and the neg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com