Logging-while-drilling underground circuit semiconductor positive cooling system and method

A semiconductor and circuit technology, used in cooling systems, active semiconductor cooling systems and cooling fields along with drilling circuits, can solve problems such as limited high temperature resistance, and achieve the effects of ensuring cooling, improving life and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

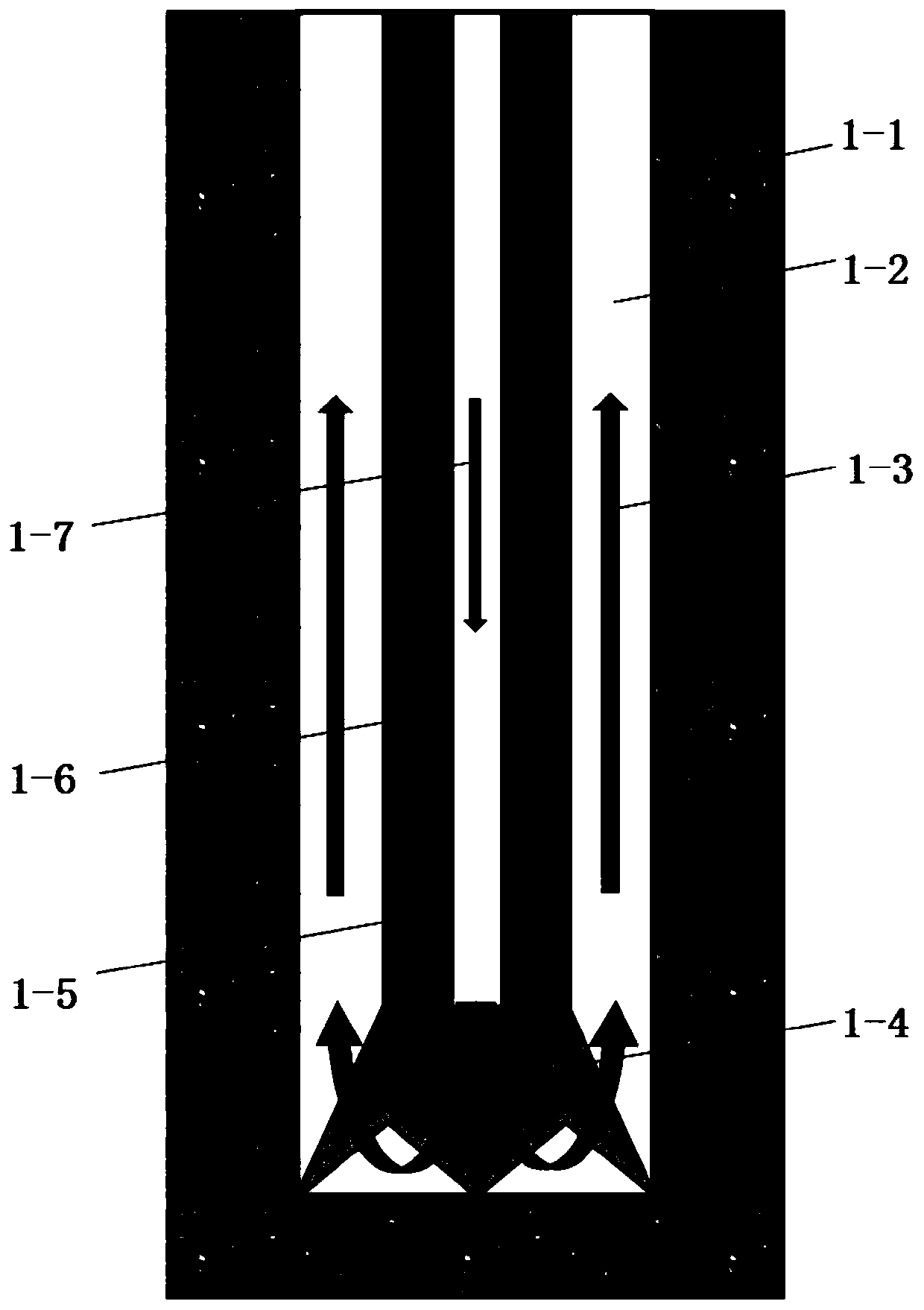

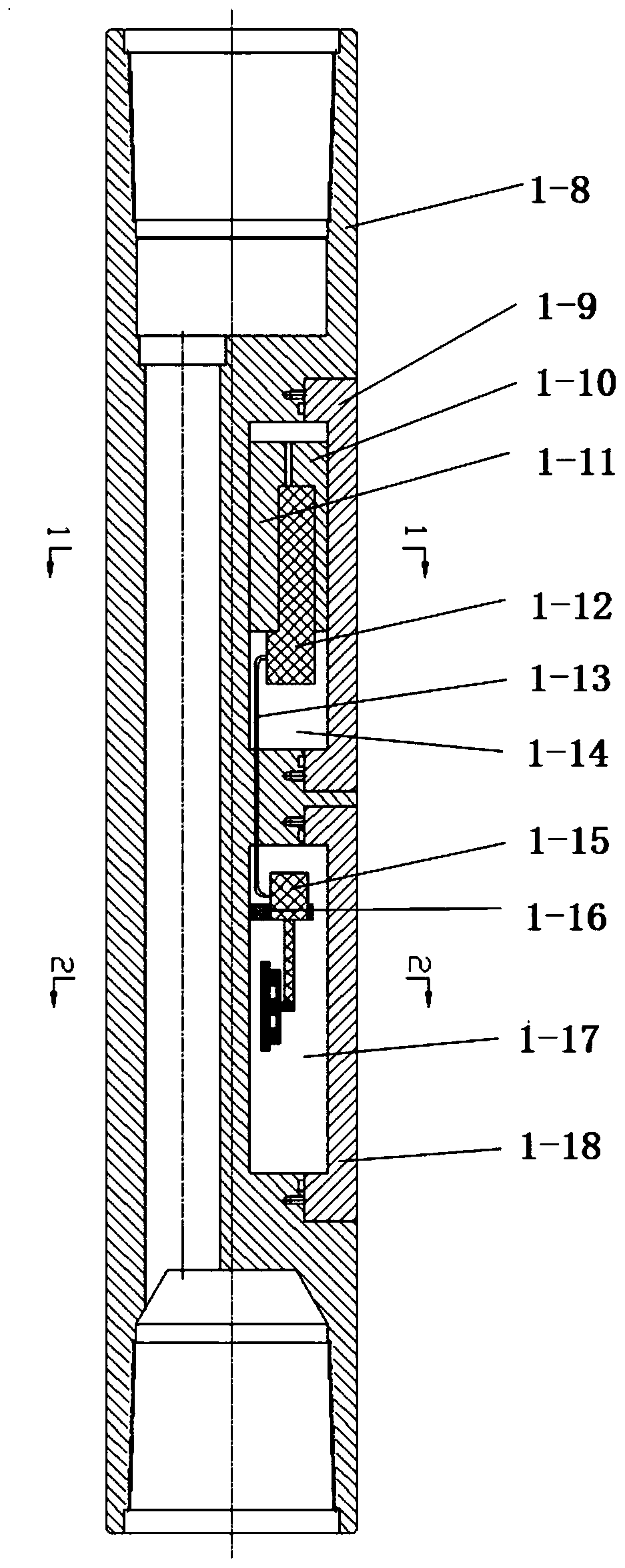

[0032] In Example 1, a Stirling refrigerator is used to reduce the downhole circuit temperature. The Stirling refrigerator adopts the principle of gas regenerative refrigeration, and its structural characteristics are: no valve is used to distribute gas between the compression part and the expansion part, the compression part and the expansion part are integrated, coupled by the corresponding mechanism, with the same frequency operation. It is this structure that realizes the refrigeration cycle process of isothermal compression, constant volume heat release, isothermal expansion, and constant volume heat absorption. During the refrigeration cycle, the cooling load generated by the cold finger of the Stirling refrigerator is evenly transmitted to each electronic component or sensing component through the T-shaped heat conduction block, thereby reducing the temperature of the entire circuit and avoiding shortening its life. or failure occurs.

[0033] Based on the above princ...

Embodiment 2

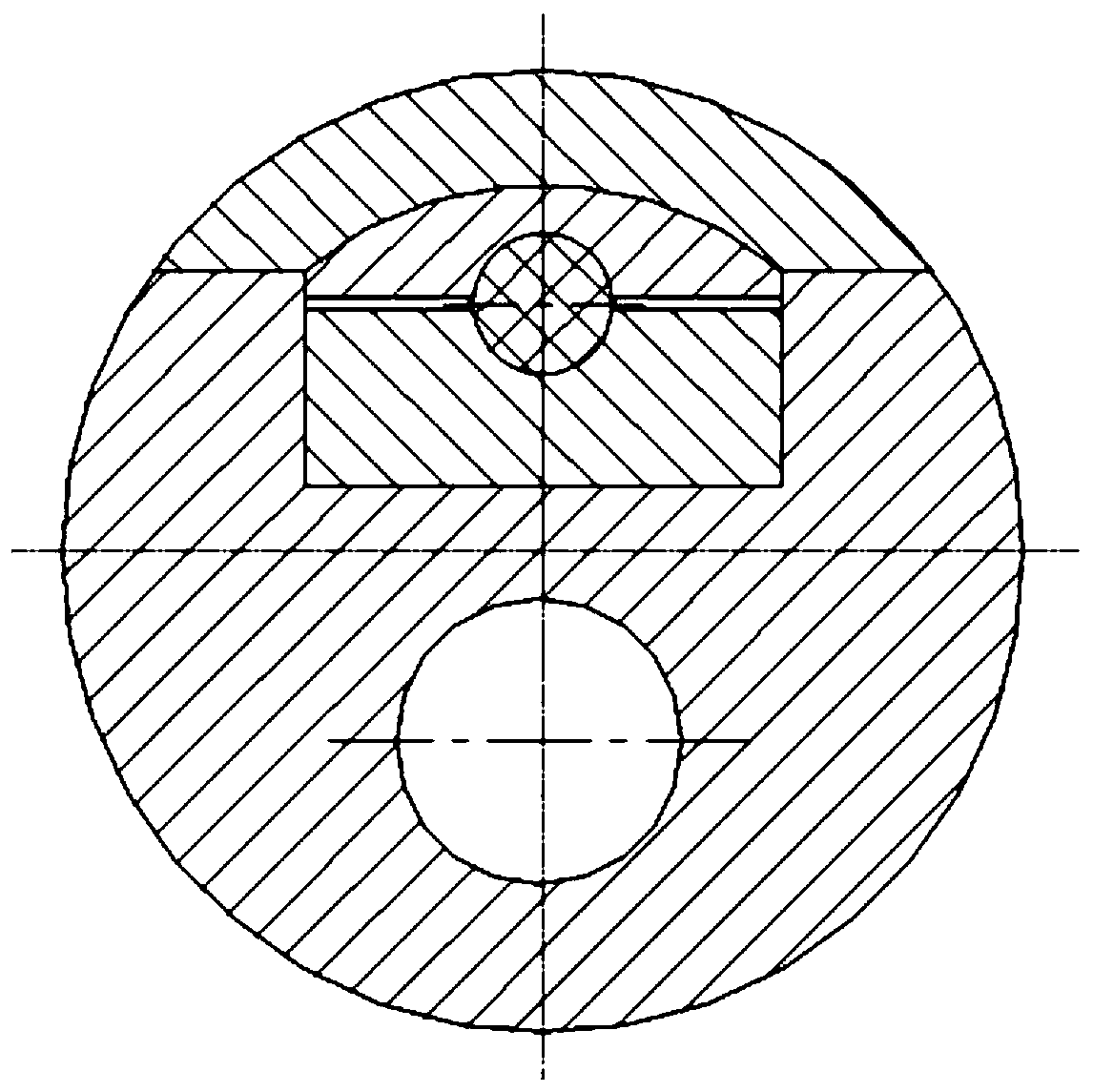

[0050] In Example 2, semiconductor refrigeration chips are used to reduce the temperature of downhole circuits. Its working principle is: after the semiconductor cooling chip is powered on, the electrons start from the negative electrode, first pass through the P-type semiconductor, and absorb heat there; then the electrons move to the N-type semiconductor, and then release the heat. Every time a PN module is passed, the heat is transferred from one side to the other; a large number of N-type and P-type semiconductors are arranged to form a whole, which becomes a semiconductor cooling chip. The overall effect is that the heat is transferred from one side of the semiconductor cooling chip to the other. On the one hand, a temperature difference is created, thus forming a cold end and a hot end. Relying on the cooling effect of the semiconductor refrigeration sheet, the heat generated by the downhole circuit is transferred to the shell through the interaction of the heat conducti...

Embodiment 3

[0067] In Example 3, semiconductor refrigeration chips and phase change materials are used to reduce the downhole circuit temperature. Its working principle is: after the semiconductor cooling chip is powered on, the electrons start from the negative electrode, first pass through the P-type semiconductor, and absorb heat there; then the electrons move to the N-type semiconductor, and then release the heat. Every time a PN module is passed, the heat is transferred from one side to the other; a large number of N-type and P-type semiconductors are arranged to form a whole, which becomes a semiconductor cooling chip. The overall effect is that the heat is transferred from one side of the semiconductor cooling chip to the other. On the one hand, a temperature difference is created, thus forming a cold end and a hot end. The heat generated by the downhole circuit enters the phase-change material through the heat-conducting material, and then the end face of the phase-change material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com