Preparation method of bulletproof helmet

A technology of bulletproof helmets and helmets, which is applied to other household appliances, household appliances, household components, etc., can solve the problems of poor mechanical properties, large bullet-back surface, and low melting point, so as to achieve light weight, reduce secondary injuries, and improve maneuverability. Effects on capacity and survivability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

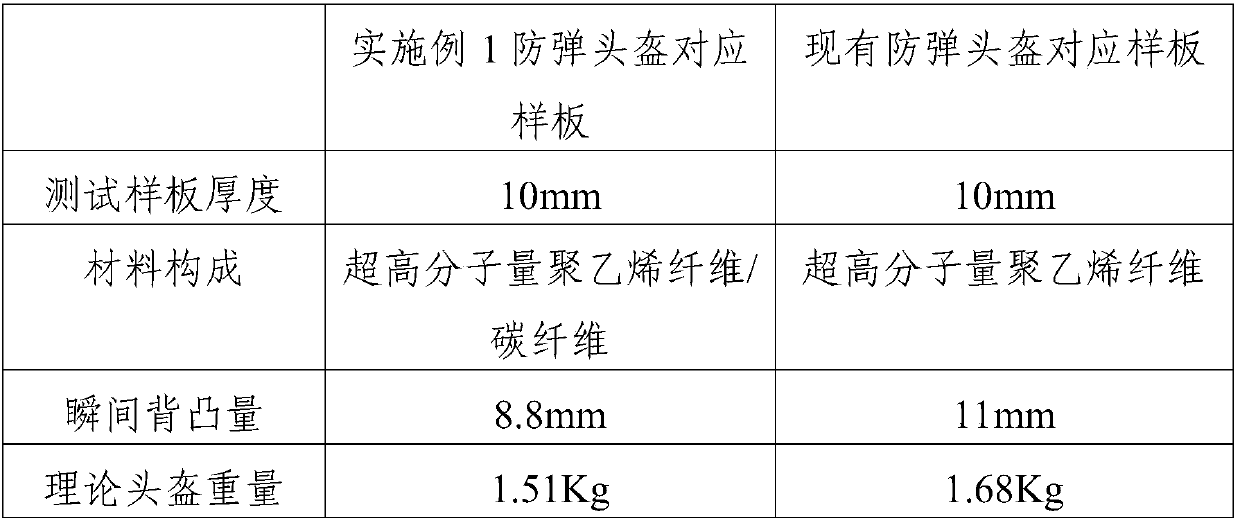

Embodiment 1

[0029] A preparation method of a bulletproof helmet, comprising the following steps:

[0030] (1) Lay up the base material UHMWPE fiber and carbon fiber separately, wherein the UHMWPE fiber ply is overlapped with 53 layers at 90 degrees and 0 degrees; the carbon fiber layer is 90 degrees and 0 degrees. 9 layers are laid on top of each other; the basic material distribution method is: the impact surface is ultra-high molecular weight polyethylene fiber, and the back convex blocking surface is carbon fiber;

[0031] (2) After the layup is completed, apply high-toughness epoxy resin on the joint position of the ultra-high molecular weight polyethylene fiber and the carbon fiber layup, place the laminated material on the helmet mold, and wrap it in a high-temperature-resistant vacuum bag. The good tablet is evacuated, and the vacuum pressure is kept at 0.8-1.5MPA, and it is placed in a curing oven at a temperature of 120-130°C for 90 minutes.

Embodiment 2

[0033] A preparation method of a bulletproof helmet, comprising the following steps:

[0034] (1) Lay up the base material UHMWPE fiber and carbon fiber respectively, wherein the UHMWPE fiber plies are laid 56 layers at 90 degrees and 0 degrees; the carbon fiber layers are staggered at 45 degrees. Lay 7 layers; the distribution mode of the basic material is: the impact surface is ultra-high molecular weight polyethylene fiber, and the back convex blocking surface is carbon fiber;

[0035](2) After the layering is completed, apply high-toughness epoxy resin at the joint position of the ultra-high molecular weight polyethylene fiber and the carbon fiber layer, place the layered material on the helmet mold, and use a 300-ton flat vulcanizing machine to press molding , keep the pressure at 15 ~ 17Kg, the temperature at 120 ~ 130 ℃, keep it for 90 minutes, demould and form.

Embodiment 3

[0037] A preparation method of a bulletproof helmet, comprising the following steps:

[0038] (1) The ultra-high molecular weight polyethylene fiber layer is laid 50 layers overlapping each other at 90 degrees and 0 degrees; after the layering is completed, it is separately formed on the mold, the temperature is 120 ~ 130 ° C, the pressure is 15 ~ 17Kg, and the molding time is 90 minutes to form an ultra-high molecular weight polyethylene fiber helmet;

[0039] (2) 12 layers of carbon fiber layers overlapped at 90 degrees and 0 degrees. After the layers are completed, they are individually formed on the mold, the temperature is 120-130°C, the pressure is 12-15Kg, and the molding time is 90 minutes to form a carbon fiber helmet. ;

[0040] (3) The outer surface of the carbon fiber helmet in step (2) is evenly coated with a thermosetting polyurethane adhesive layer with a thickness of 0.3 mm, and the ultra-high molecular weight polyethylene fiber helmet and the carbon fiber hel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com