Nanowire array, optoelectronic device and manufacturing method thereof

A technology of nanowire arrays and optoelectronic devices, applied in nanostructure manufacturing, semiconductor/solid-state device manufacturing, nano-optics, etc., can solve the problems of reducing material quality, achieve flexible heterojunction structure, simple device process, and low defects effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

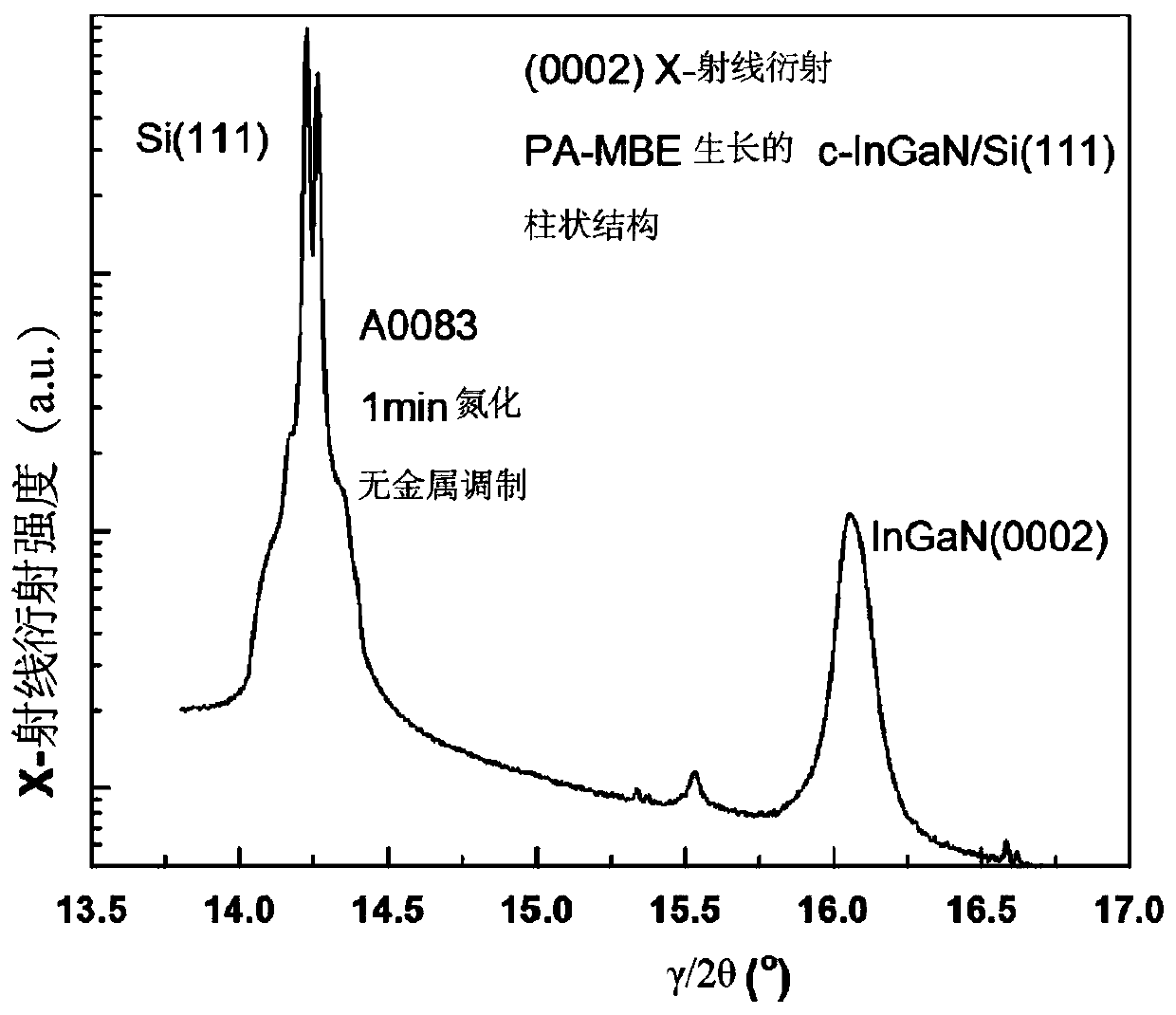

[0044] In this example, a three-dimensional dense layered structure composed of one-dimensional InGaN nanowires is prepared through the following steps:

[0045] 1) Provide a Si(111) substrate through nitriding treatment;

[0046] 2) On the Si(111) substrate, one-dimensional InGaN nanowires were epitaxially grown using plasma-assisted molecular beam epitaxy equipment (Vecco Gen II), and the specific settings were as follows:

[0047] Adjust the In / Ga total metal beam current to obtain a growth rate of about 0.5 μm / h;

[0048] By adjusting the In / Ga beam current ratio to 5 and the growth temperature at 450°C, the active N beam current is three times that of the metal In / Ga beam current.

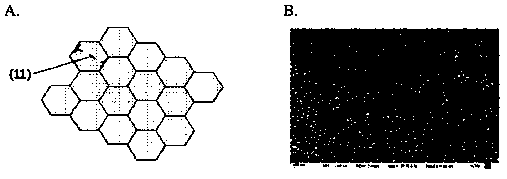

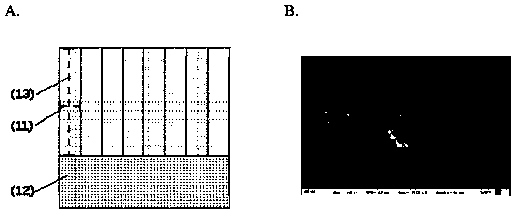

[0049] Through the above method, a three-dimensional dense InGaN structure (such as figure 1 with figure 2 As shown), the thickness of the InGaN three-dimensional dense structure is about 600nm.

[0050] figure 1 A is a top view of a schematic three-dimensional dense structure of InGaN, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com