Organic silica gel membrane with clear lines and preparation method of membrane

A technology of organic silica gel and texture, applied in the field of organic silica gel film and its preparation, can solve the problems of unclear texture accuracy, broken release paper, difficult to reuse, etc., to achieve fine and clear texture, fast molding speed, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A method for preparing an organic silica gel membrane with clear lines, comprising the steps of:

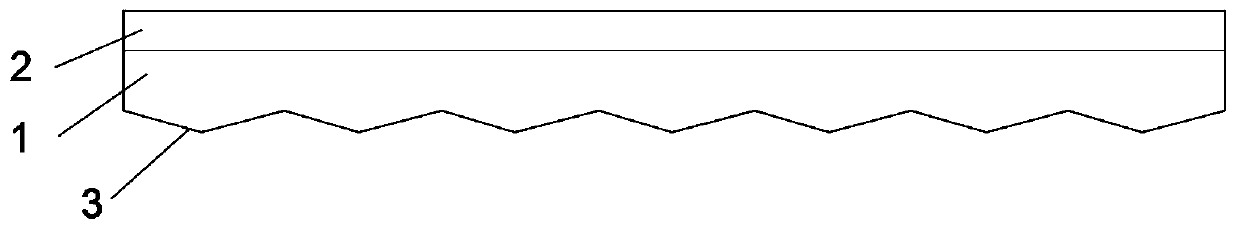

[0023] Step 1, prepare the substrate film 4 with optical visual texture on the surface;

[0024] Step 2, making the surface of the substrate film with optical visual texture have an easy-to-peel function, so as to obtain a master mold, and the easy-to-peel function makes it easy to peel off the master mold after coating silica gel;

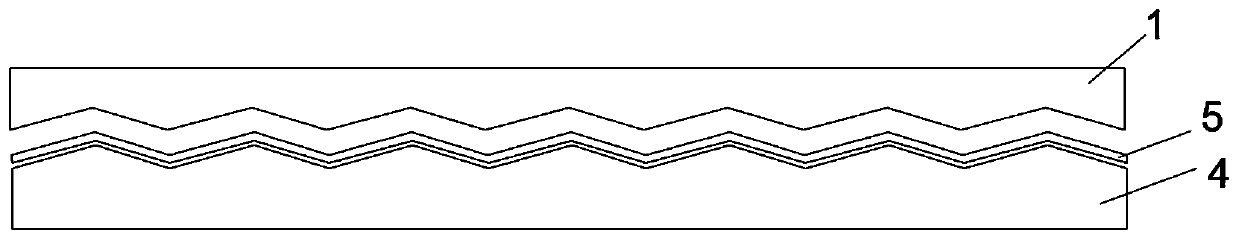

[0025] Step 3: Coating the liquid silicone on the master mold, peeling off the liquid silicone from the master mold after curing, and preparing the silicone film 1 with an optical texture on the surface.

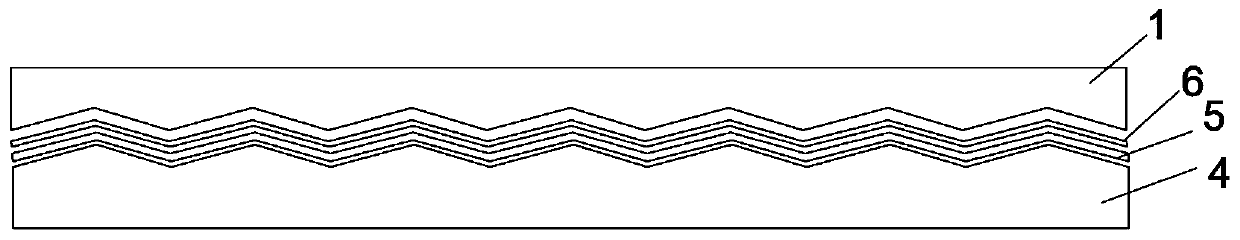

[0026] Preferably, in step 2, the surface of the substrate film with optical visual texture is subjected to vacuum electroplating to form an electroplated base film 6 with an easy-to-peel function. The vacuum pressure for vacuum electroplating is 0.001Pa. The electroplating base film is chrome-plated base film or copper-plated base film or ...

Embodiment 1

[0039]Embodiment one, 1) choose the PET base material that thickness is 0.1mm, carry out vacuum electroplating to the PET base material surface with nano-scale optical texture, make master model, the vacuum pressure during vacuum plating is 0.001Pa, make organic The peel force between the silica gel film and the electroplating base film is less than 25g, the vacuum pressure for vacuum plating is 0.001Pa, the electroplating base film is chrome-plated base film or copper-plated base film or nickel-plated base film or aluminum-plated base film, nickel-plated base film The film is not easy to oxidize and can be used repeatedly for several months. The copper-plated base film can increase the texture brightness and make the texture transferred on the surface of the silicone more dazzling. The gloss of the electroplating base film is 0-60. The surface texture is more delicate and complete. When the gloss is 60, the surface texture is incomplete after the silica gel is peeled off, and ...

Embodiment 2

[0040] Embodiment two, 1) select the PET base material that thickness is 0.1mm, apply UV adhesive 5 to the surface of PET base material, the temperature is 40 ℃ when coating UV topcoat, utilize UV adhesive coating 5 to spread on the base material of tool pattern On the surface of the film 4, the UV glue completely penetrates into the texture of the substrate film 4 to form corresponding textures, and the UV glue is cured and hardened by irradiating UV light. There is no limit to the thickness of the master model of the texture and the coating of the UV topcoat, and it is set according to the different needs of different customers. After the liquid silica gel is solidified, it is peeled off from the master mold to obtain a patterned silicone film. The surface of the silicone film processed by the process of the present invention has nano-scale PET optical UV texture, and the texture is clear.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com