Nitrogen-doped 3D porous carbon material modified by carbon nanoparticles and preparation and application thereof

A carbon nanoparticle, porous carbon material technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as high price and complex process, and achieve simple methods, low costs, and simplification. effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

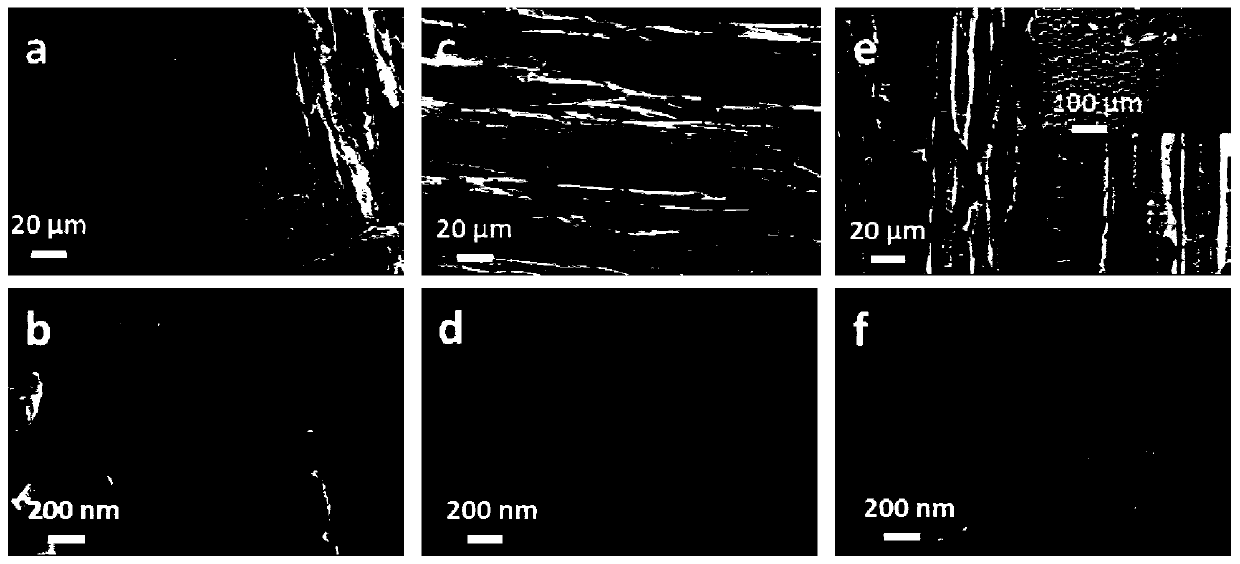

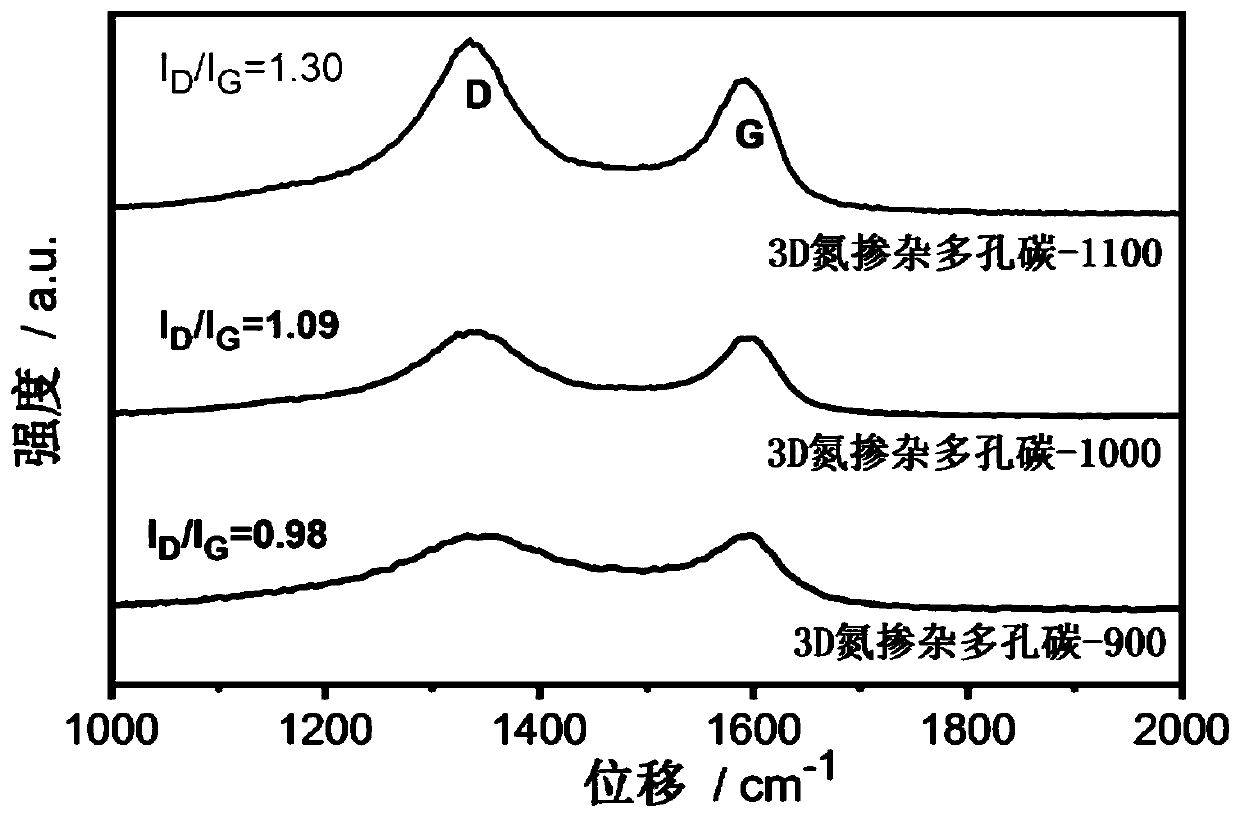

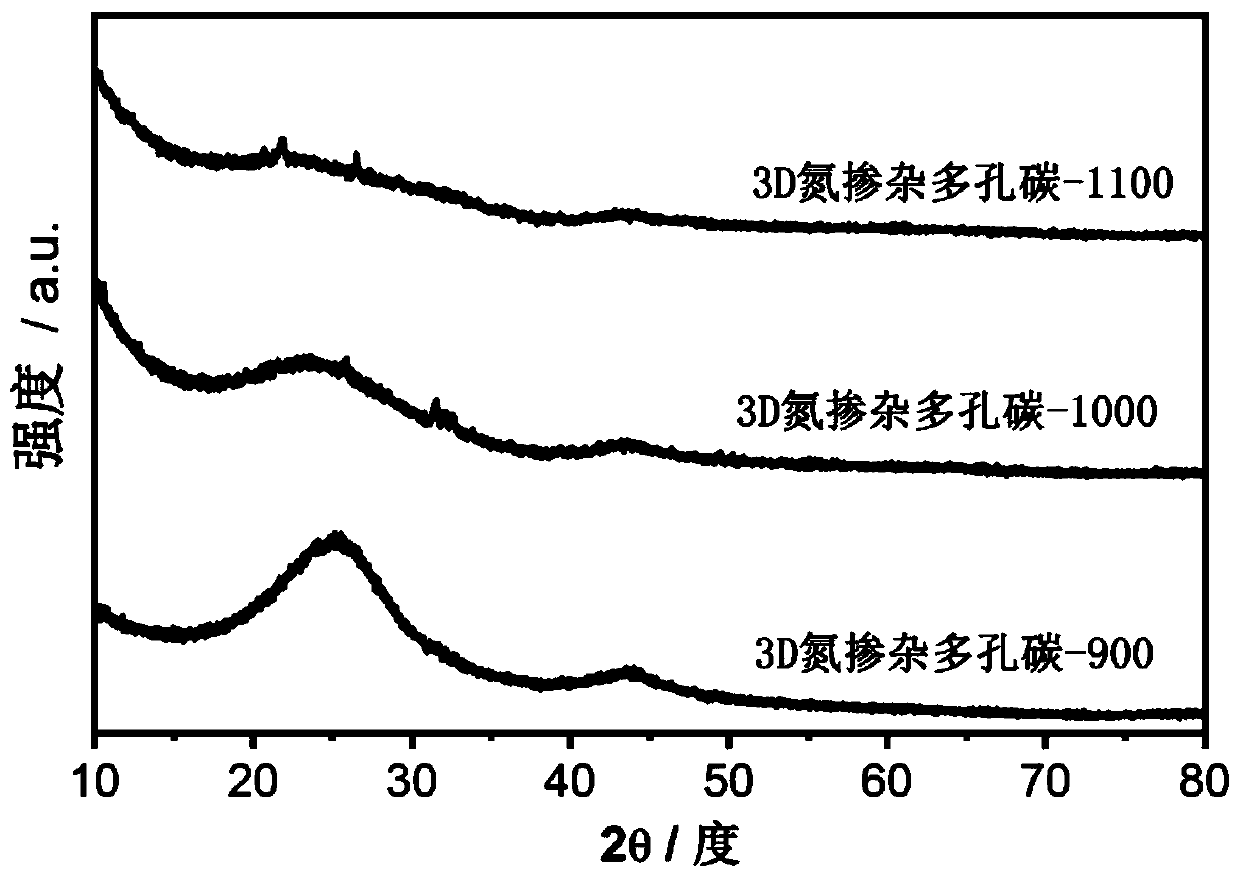

[0032] Disperse 2g of eucalyptus in 50mL of deionized water, and carry out hydrothermal carbonization treatment in a hydrothermal reaction kettle. wood; the eucalyptus wood pretreated by hydrothermal carbonization was carbonized in an ammonia atmosphere, the carbonization temperature was 1000°C, the carbonization was kept for 2 hours, and the heating rate was 5°C / min. Nitrogen-doped 3D porous carbon materials decorated with carbon nanoparticles.

Embodiment 2

[0034] Disperse 2 g of eucalyptus in 50 mL of deionized water, and carry out hydrothermal carbonization treatment in a hydrothermal reaction kettle. The hydrothermal carbonization temperature is 200 ° C, and the hydrothermal carbonization time is 24 hours; after that, filter and wash to obtain hydrothermal carbonization pretreated eucalyptus wood; the eucalyptus wood pretreated by hydrothermal carbonization was carbonized in an ammonia atmosphere, the carbonization temperature was 1000°C, the carbonization was kept for 2 hours, and the heating rate was 5°C / min. Nitrogen-doped 3D porous carbon materials decorated with carbon nanoparticles.

Embodiment 3

[0036] Disperse 2g of eucalyptus in 50mL of deionized water, and carry out hydrothermal carbonization treatment in a hydrothermal reaction kettle. Wood; the eucalyptus wood pretreated by hydrothermal carbonization was carbonized in an ammonia atmosphere, the carbonization temperature was 900 °C, the carbonization was kept for 2 hours, and the heating rate was 5 °C / min. Nitrogen-doped 3D porous carbon materials decorated with carbon nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com