Cylindrical concrete masonry block forming machine and method

A technology of concrete blocks and cylinders, which is applied to ceramic molding machines, chemical instruments and methods, and clay preparation devices, etc., can solve the problems of large floor area of the production line, large labor costs, and high labor intensity of operators. The effect of reducing occupied space and improving molding efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

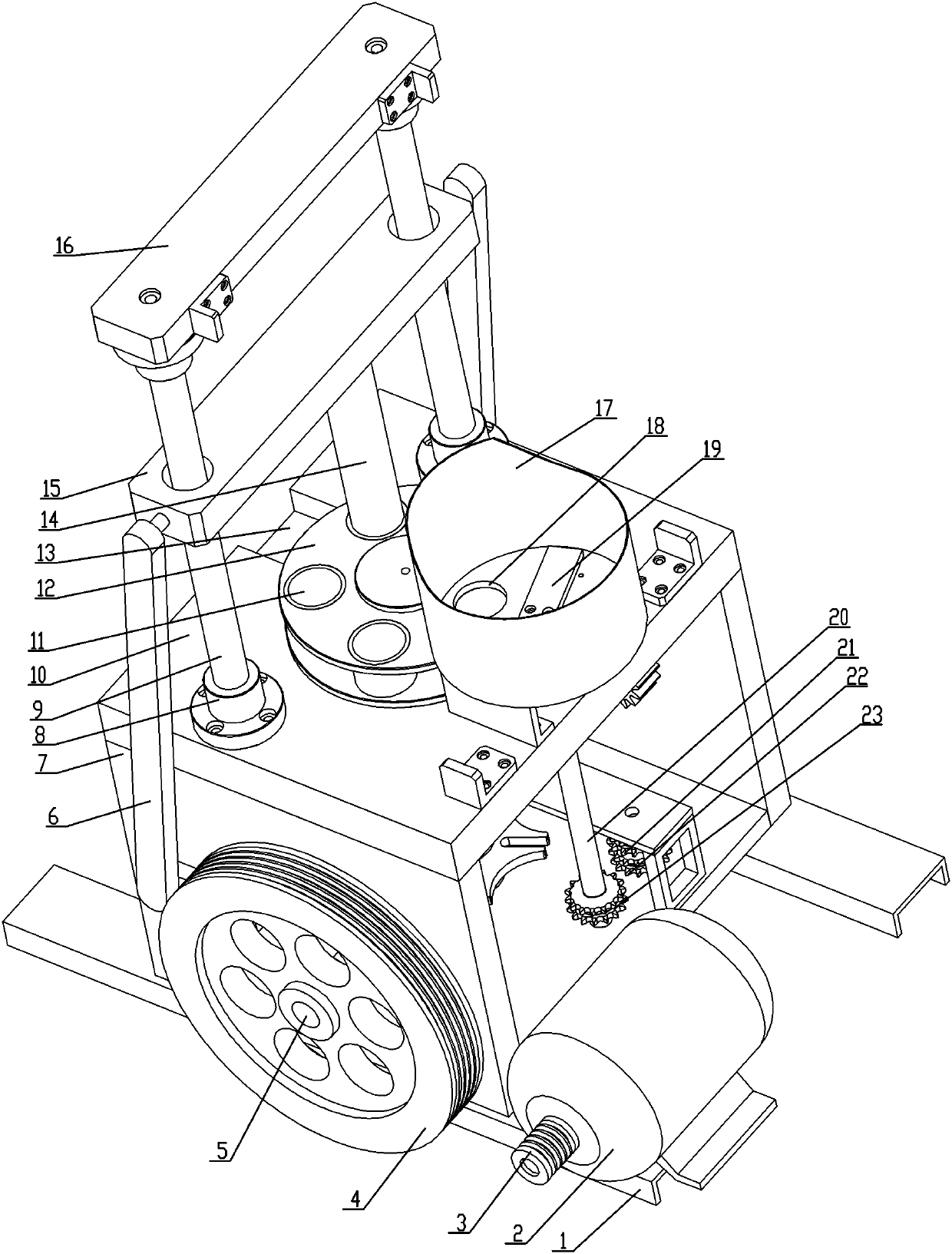

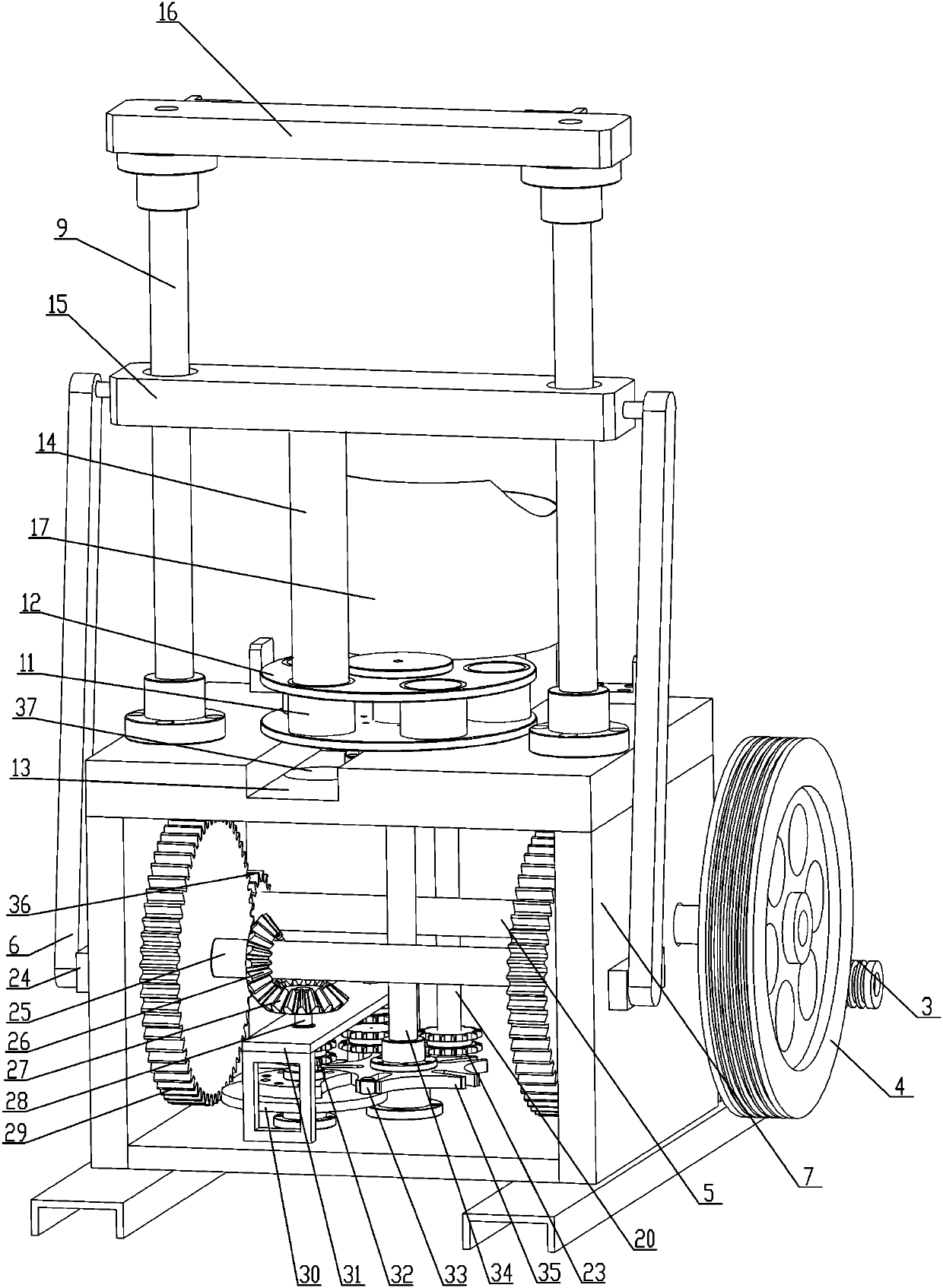

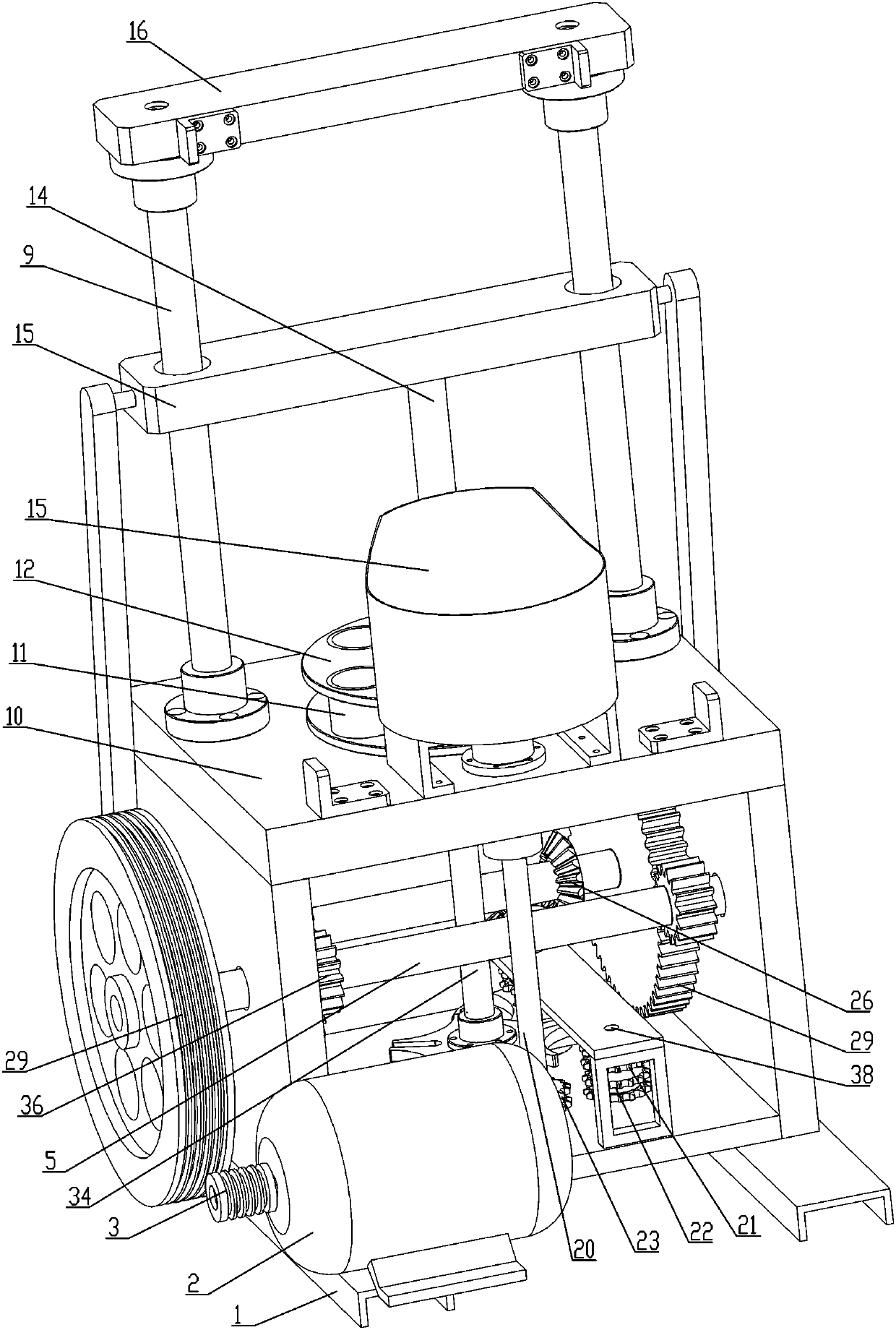

[0033] see Figure 1-3 , a cylindrical concrete block forming machine, which includes a frame 1, and the top of the frame 1 is symmetrically fixed with a vertical plate 7 on both sides, and the top of the vertical plate 7 is fixedly mounted with a top plate 10, and the top plate 10 The middle part of the top is supported with a mold turntable 12, and a plurality of molding mold cylinders 11 are evenly distributed on the mold turntable 12; the turntable main shaft 34 of the mold turntable 12 is connected with a ratchet mechanism and drives it to rotate; the ratchet mechanism passes The gear transmission assembly is connected with the power unit; a stirring lower barrel 17 for blanking is arranged directly above the mold turntable 12, and a stirring plate 19 is arranged inside the stirring lower barrel 17, and the stirring plate 19 is connected with the stirring power The mechanism is connected, and the stirring power mechanism cooperates with the ratchet mechanism through the c...

Embodiment 2

[0042] The method for forming a cylindrical concrete block by any one of the cylindrical concrete block forming machines comprises the following steps:

[0043] Step1: Put the mixed concrete material into the lower mixing barrel 17, and start the motor 2 of the power unit;

[0044] Step2: The driving pulley 3 is driven by the motor 2, the driven pulley 4 is driven by the driving pulley 3, the first main shaft 5 is driven by the driven pulley 4, the driving gear 36 is driven by the first main shaft 5, and the driving gear 36 is driven Drive driven gear 29, and then drive driving bevel gear 26 by driven gear 29, drive driven bevel gear 27 by driving bevel gear 26 again;

[0045] Step3: Drive the first vertical shaft 28 through the driven bevel gear 27, drive the ratchet mechanism through the first vertical shaft 28, drive the second vertical shaft 34 step by step through the ratchet mechanism, and then drive the mold turntable 12 to rotate step by step by the second vertical sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com