Composite board with high gloss liner, high gloss liner and refrigerator

A composite board and liner technology, which is applied in lighting and heating equipment, chemical instruments and methods, synthetic resin layered products, etc., can solve the problems of poor impact resistance, glossiness not reaching gloss, and liner glossiness decline And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

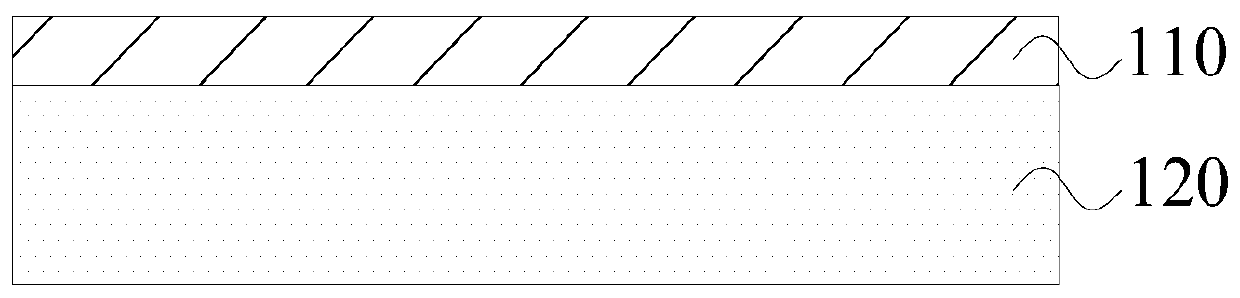

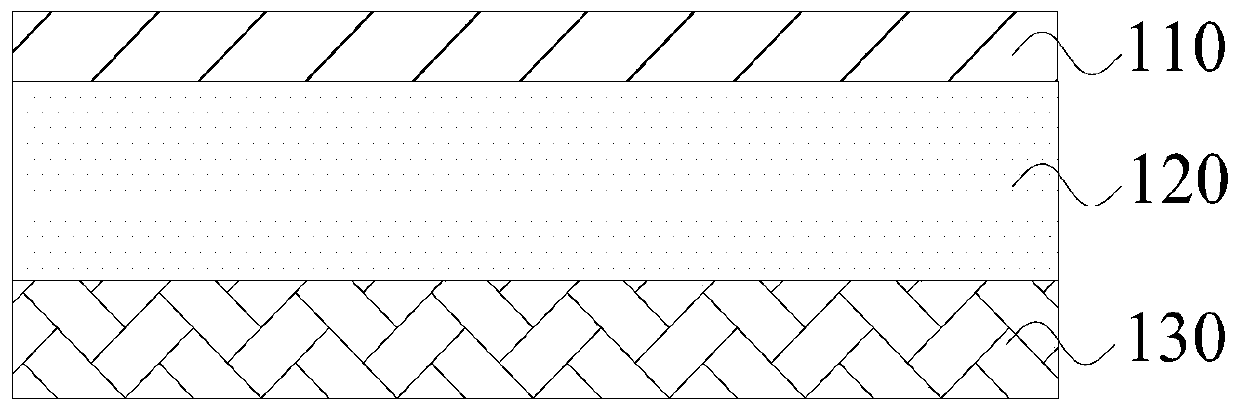

Image

Examples

Embodiment 1

[0055] In this example, the high-gloss styrene material A is prepared first, and then the composite sheet of the high-gloss liner is prepared by co-extrusion, and finally the high-gloss liner is obtained by vacuum forming the composite sheet. The specific steps are as follows:

[0056] (1) 70 parts of GPPS and 30 parts of styrene-butadiene block copolymer are melted, blended, extruded and granulated by a twin-screw extruder to obtain high-gloss styrene material A; wherein, GPPS is processed at 200 degrees Celsius and 5kg pressure The melt index under 10 minutes can be 2g, and the weight-average molecular weight of GPPS is 200,000, and the weight percent of butadiene in the styrene-butadiene block copolymer is 40%; And, the screw of twin-screw extruder The diameter is 60 mm, the aspect ratio is 35, the temperature of the barrel is 180-210 degrees Celsius, the vacuum degree is less than 0.1 MPa, and the temperature of the mold is 170-220 degrees Celsius.

[0057] (2) The high-g...

Embodiment 2

[0063] In this example, the high-gloss styrene material A, the composite board and the high-gloss liner were sequentially prepared according to the same method and conditions as in Example 1. The difference is that in this embodiment: the ratio of GPPS to styrene-butadiene block copolymer is 60 parts: 30 parts, the melt index of GPPS at 200 degrees Celsius and 5kg pressure for 10 minutes can be 20g, and the GPPS The weight average molecular weight is 400,000, and the weight percent of butadiene in the styrene-butadiene block copolymer is 75%.

[0064] The high-gloss styrene material A prepared in this embodiment has a tensile strength of 41MPa, a flexural modulus of 2.5GPa, and an Izod beam cooling void impact strength of 5KJ / m 2 , The glossiness of 60 degree angle is 103.

[0065] The glossiness of the composite plate prepared in this embodiment at an angle of 60 degrees is 102.

[0066] The high-gloss liner prepared in this embodiment has a glossiness of 96-102 at an angle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com