Acidic dye composition and dye product thereof

A dye composition and acid dye technology, applied in the field of textile printing and dyeing, can solve the problems of inability to dye in one bath, poor dyeing effect and high dyeing cost, and achieve the effects of excellent light fastness, short production cycle and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

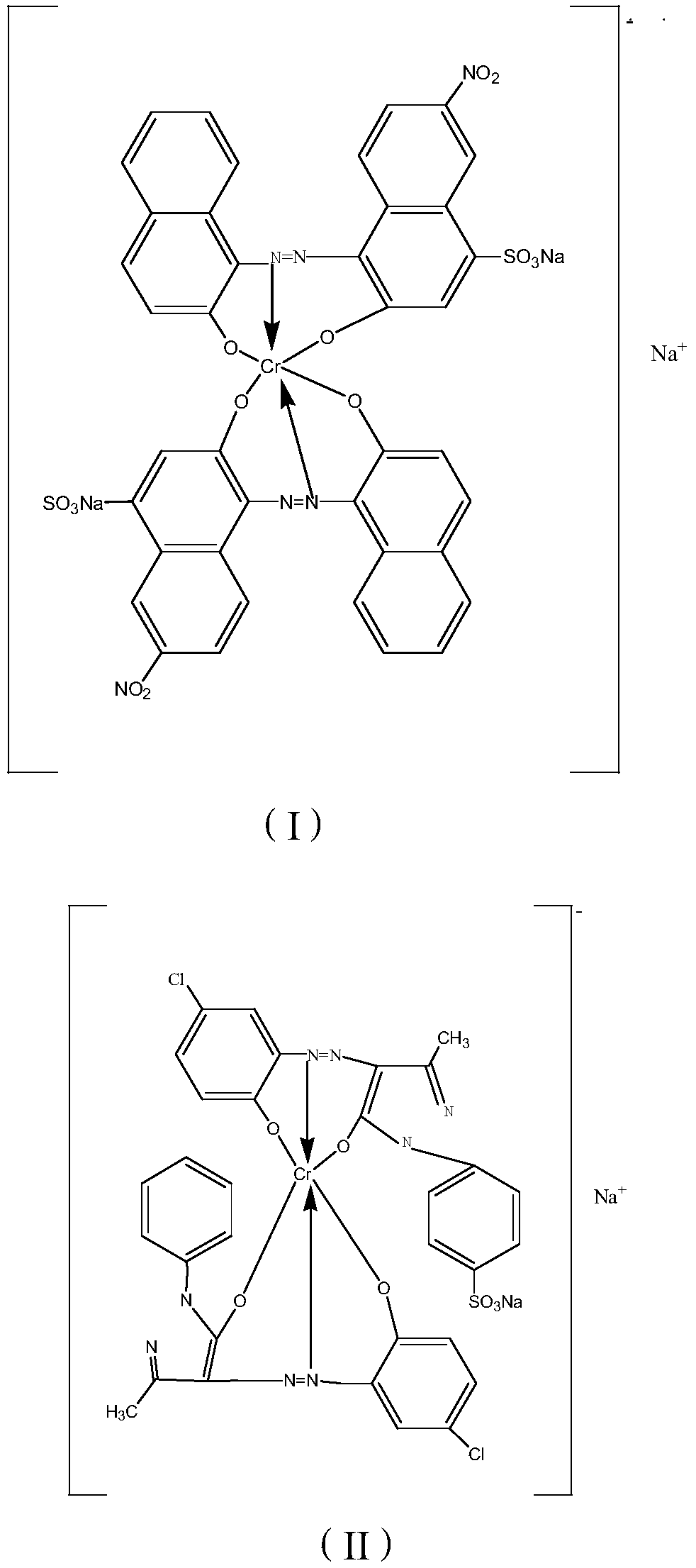

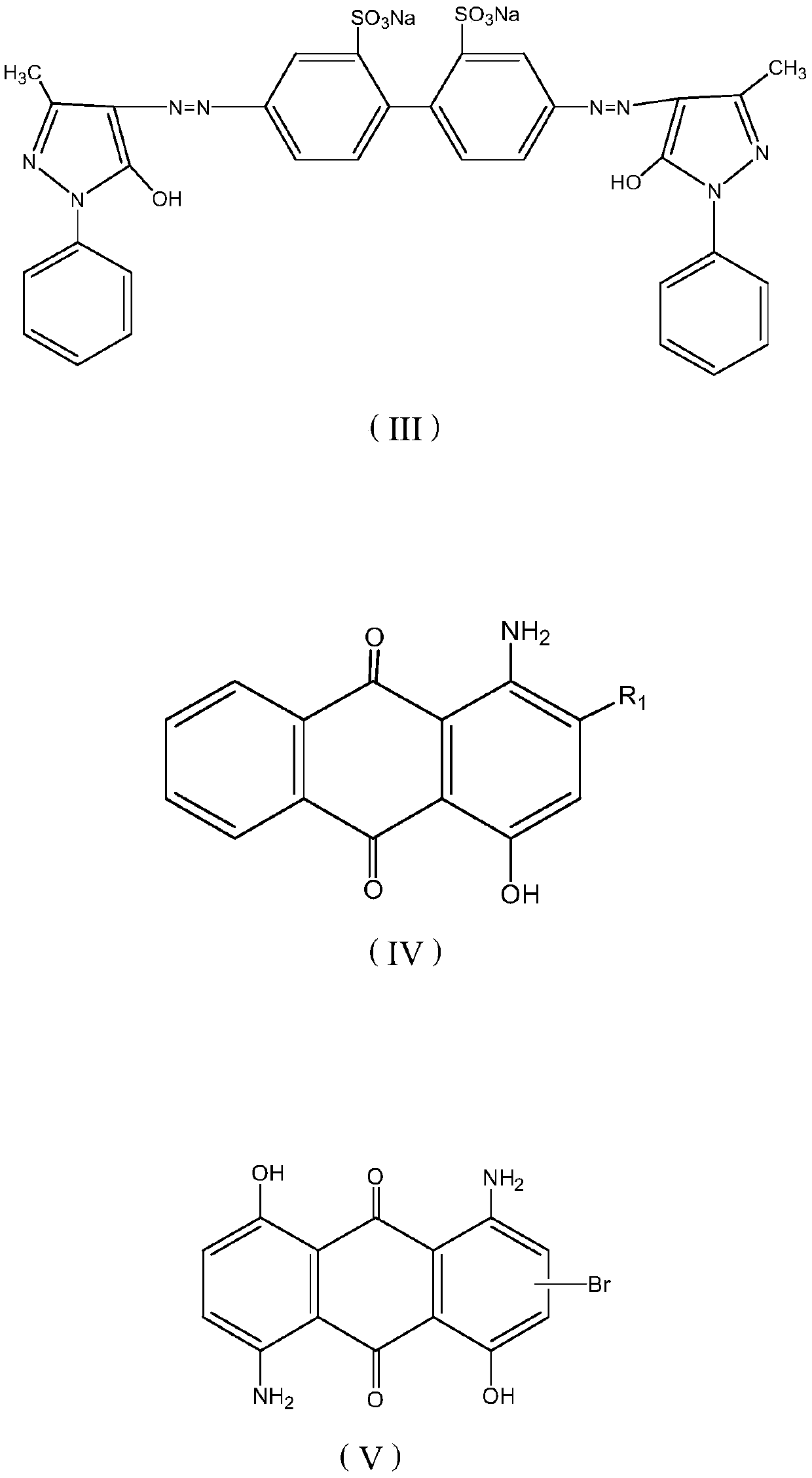

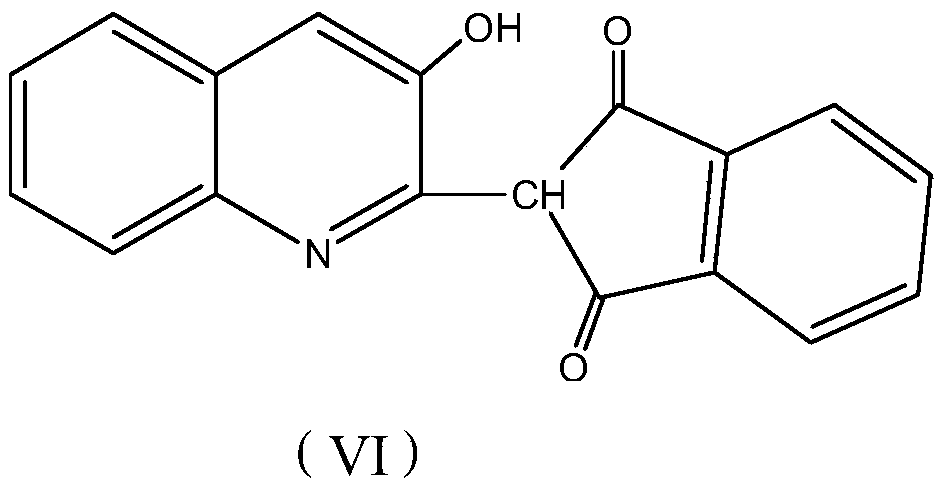

Method used

Image

Examples

Embodiment 1

[0035] In the embodiment of the present invention, based on the total weight of the acid dye composition, by weight percentage, it is 13% of compound A, 2% of compound B, 1.5% of compound C, 27% of compound D, and 9% of compound E , 22% of compound F and 25.5% of dispersing agent, wherein the dispersing agent is formed by compounding sodium methylnaphthalene sulfonate formaldehyde condensate and sodium lignosulfonate in a weight percentage of 3:7, adding water and beating After mixing, disperse with a grinder, spray dry, and finally form a finished product.

Embodiment 2~9

[0037] According to the method of Example 1, according to the composition of Compound A, Compound B, Compound C, Compound D, Compound E and Compound F shown in Table 1, the acid dye composition of the embodiment of the present invention can also be obtained, which also has light fastness Fastness, sublimation fastness, soaping fastness and rubbing fastness.

[0038] Table 1

[0039]

[0040]

[0041] In Examples 1-9 of the present invention, the process conditions of the spray drying are an inlet temperature of 120-130° C., an outlet temperature of 50-60° C., and a particle size of 0.1-1 μm.

Embodiment 10

[0043] Take 0.5g of the dispersion / acidity (owf: 0.5%) prepared in Examples 1-9, add water to 15g, make it dissolve, stir well and set to volume for later use. Take 5ml of the suspension in Plot, add 20ml of buffer solution (30g of glacial acetic acid + 90g of anhydrous sodium acetate diluted with water to 10kg), add 2.5g of cloth sample and add water to 100ml, put it into an infrared proofer, and set it at 1~1.5℃ / min, heat up from room temperature to 120°C, keep warm for 40min, start to cool down at 1-1.5°C / min and cool down to 60°C. The process is all over. After completion, rinse with clean water, dehydrate and dry the cloth sample.

[0044] The color fastness test is carried out on the cloth samples obtained after dyeing in Example 10, and the dyed cloth samples obtained by dyeing with the traditional dye dispersion / acid two-bath dyeing process are compared respectively. According to the dyeing method of the above-mentioned embodiment 10, the above-mentioned According to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com