Easy-to-pull removable adhesive tape with thermoplastic elastomer base material and preparation and using methods thereof

A thermoplastic elastomer and substrate technology, used in adhesives, film/sheet adhesives, rosin adhesives, etc. Complex composition and other problems, to achieve the effect of convenient other requirements, long-term fixed material, high tensile elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

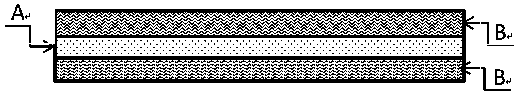

Image

Examples

Embodiment 1

[0022] The rubber glue for preparing the thermoplastic elastomer easy-pull removable tape contains the following raw materials by weight: 110 parts of SBS block copolymer, 110 parts of blended tackifying resin, of which 50 parts of Wuzhou Arakawa Chemical GA90 rosin resin, Ganzhou Taipu Chemical T115 terpene resin 60 parts, toluene 250 parts, color paste 7 parts; first dissolve GA90 rosin resin and T115 terpene resin with toluene, then add SBS block copolymer and color paste in sequence, and mix well to obtain glue ; Add 50 parts of SBS block copolymer to 100 parts of toluene solution, after the dissolution is complete, use a comma knife coating method to adjust the coating thickness, and dry to obtain a thermoplastic elastomer substrate; apply the glue to On a release paper or a release film, drying, and sticking to both sides of the thermoplastic elastomer substrate to obtain a thermoplastic elastomer substrate easy-to-pull removable tape with a thickness of 150 μm.

[0023] Wh...

Embodiment 2

[0025] The rubber glue for preparing the thermoplastic elastomer easy-pull removable tape contains the following raw materials by weight: 110 parts of SBS block copolymer, 120 parts of blended tackifying resin, of which 60 parts of Wuzhou Arakawa Chemical GB75 rosin resin, Shanghai Shuixing Chemical T105 terpene resin 60 parts, toluene 280 parts, color paste 7 parts; first dissolve GB75 rosin resin and T105 terpene resin with toluene, then add SBS block copolymer and color paste in sequence, and mix well to obtain glue ; Add 50 parts of SBS block copolymer to 100 parts of toluene solution, after the dissolution is complete, use a comma knife coating method to adjust the coating thickness, and dry to obtain a thermoplastic elastomer substrate; apply the glue to It is dried on release paper or release film, and pasted on both sides of the thermoplastic elastomer substrate to obtain an easy-pull removable tape with a thickness of 200 μm on the thermoplastic elastomer substrate.

[0...

Embodiment 3

[0028] The rubber glue for preparing the thermoplastic elastomer easy-pull removable tape contains the following raw materials by weight: 140 parts of SIS block copolymer, 110 parts of blended tackifying resin, of which 50 parts of Wuzhou Arakawa Chemical GB125 rosin resin, Shanghai Shuixing Chemical Industry T105 terpene resin 60 parts, toluene 330 parts, color paste 7 parts; first dissolve GB125 rosin resin and T105 terpene resin with toluene, then add SIS block copolymer and color paste in sequence, and mix well to obtain glue ; Add 60 parts of SIS block copolymer to 70 parts of toluene solution. After the dissolution is complete, use a comma knife coating method to adjust the coating thickness, and dry to obtain a thermoplastic elastomer substrate; apply the glue to On the release paper or release film, dry, and adhere to both sides of the thermoplastic elastomer substrate to obtain a thermoplastic elastomer substrate easy-to-pull removable tape with a thickness of 240 μm.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com