Non-electrolyte tantalum electrolytic capacitor positive and negative electrode patch welding process

A technology of tantalum electrolytic capacitors and electrolytic capacitors, which is applied in the direction of capacitors, capacitor manufacturing, capacitor terminals, etc., can solve the problems of inconvenient product fixing and increased space, and achieve increased mechanical strength, increased contact area, and guaranteed reliability in use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention is further described below in conjunction with the examples, but the scope of protection is not limited to the description.

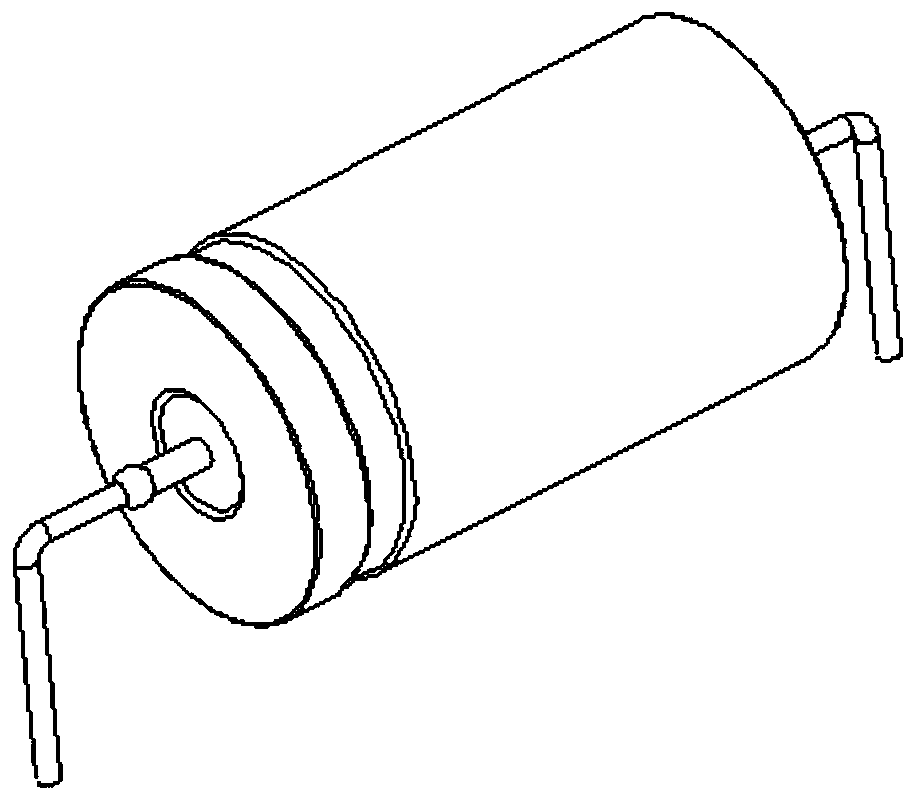

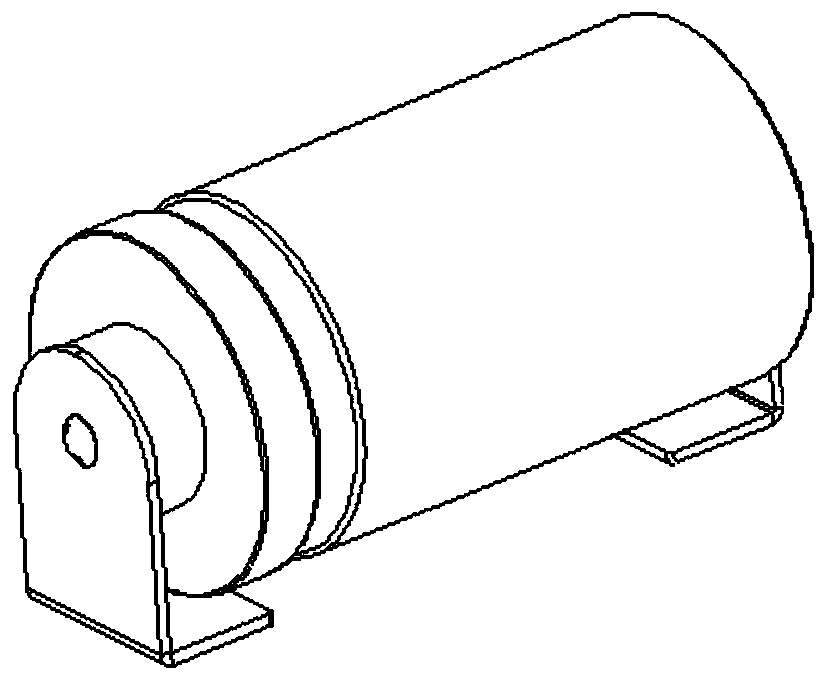

[0032] Such as Figure 1 to Figure 6 As shown, a non-electrolytic tantalum electrolytic capacitor positive and negative patch welding process, the process is to completely remove the positive lead and negative lead of the product 4 to be welded, and then the positive and negative patches 6 are welded by the plasma ball of the electrolytic capacitor, The electrolytic capacitor patch is fixed by spot welding and the electrolytic capacitor patch is fully welded and fixed on the positive and negative terminals of the electrolytic capacitor, thereby obtaining a non-electrolytic tantalum electrolytic capacitor with a positive and negative patch fixed structure.

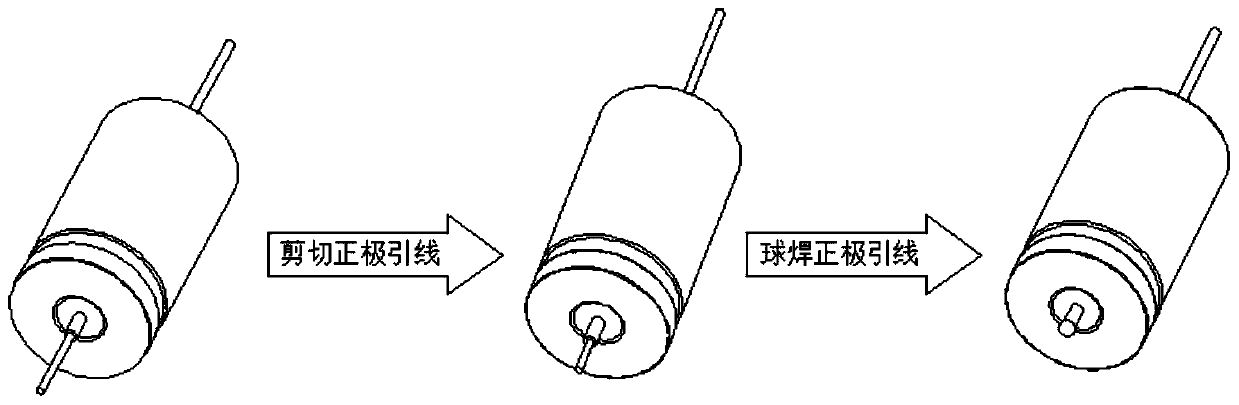

[0033] The plasma ball welding of the electrolytic capacitor includes cutting the positive electrode lead and ball welding the positive electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com