Saline-alkaline land remediation structure and method based on river channel sediment recycling

A technology for river bottom mud and structure repair, applied in chemical instruments and methods, restoration of contaminated soil, sludge treatment, etc., to achieve the effects of easy disassembly, installation and construction, wide application range, and improved use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

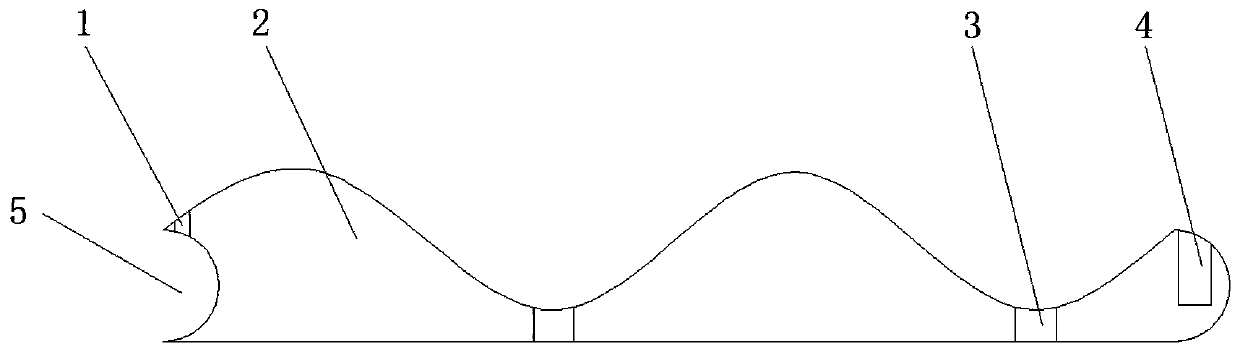

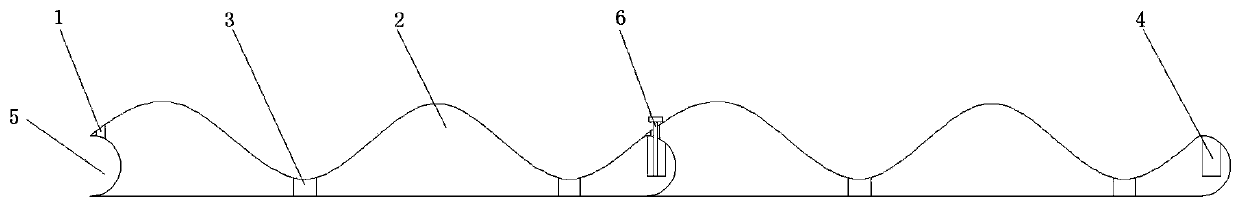

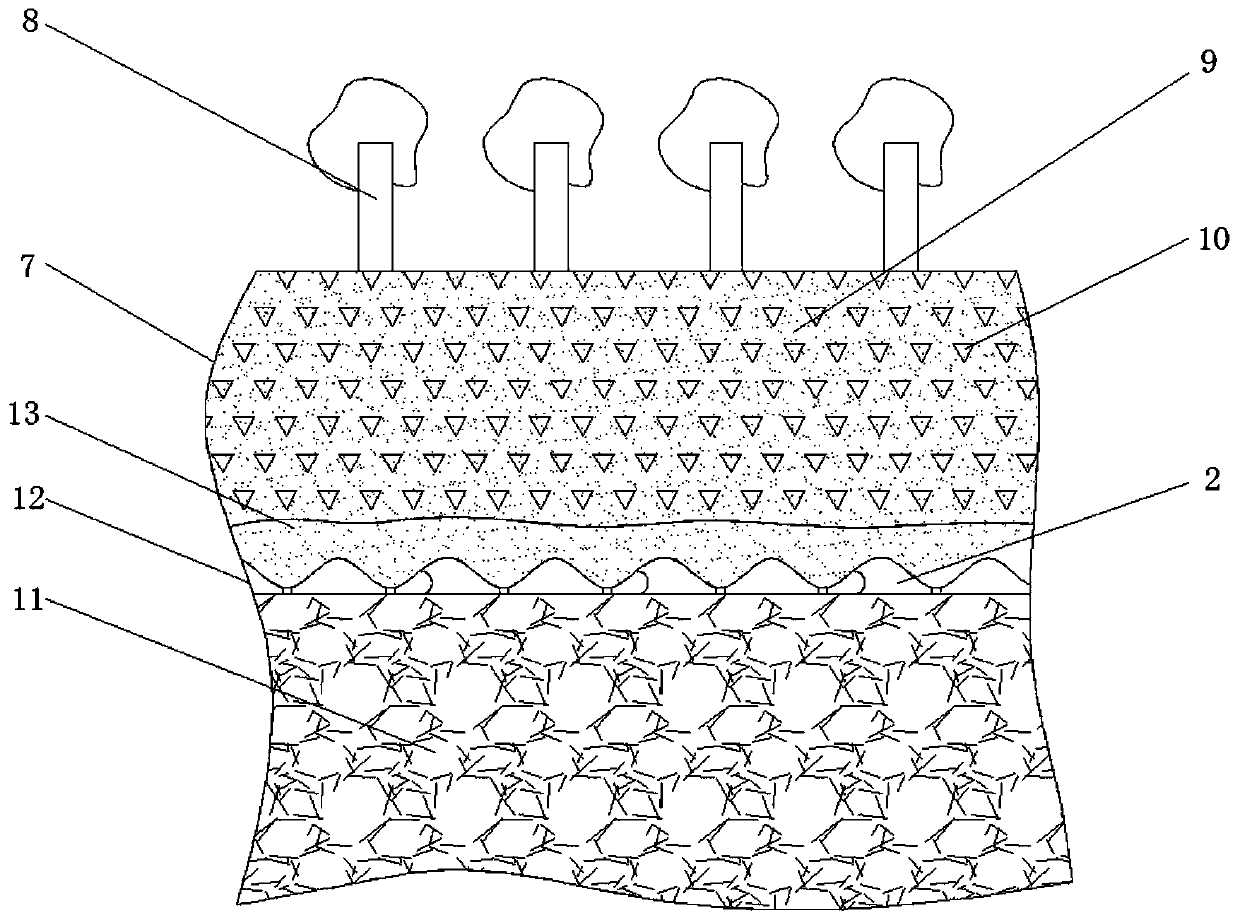

[0031] see Figure 1-3 , an embodiment provided by the present invention: a saline-alkali soil restoration structure based on the resource utilization of river sediment, including a saline-alkali soil base layer 11, a partition layer 12, a reinforcement layer 13 and an improved soil layer 7, and the saline-alkali soil base layer 11 is provided with at least one The repair tank, the depth of the repair tank is 80 cm, and the bottom of the repair tank is distributed parallel to the surface of the saline-alkali base layer 11, the partition layer 12 is laid on the upper surface of the saline-alkali base layer 11 inside the repair tank, and the top of the partition layer 12 is provided with a reinforcement layer 13 , the reinforced layer 13 is laid by weathered and dried river bottom mud, the thickness of the reinforced layer 13 is 3 cm, and the maximum is not more than 10 cm, the top of the reinforced layer 13 is provided with an improved soil layer 7, and the improved soil layer 7 i...

Embodiment 2

[0040] The difference between this embodiment and embodiment 1 is that;

[0041] The depth of the repair groove is 85 cm.

[0042] The thickness of the reinforcing layer 13 is 5 cm.

[0043] The thickness of the brick body 2 is 5 cm, and the width and length of the brick body 2 are both 25 cm.

[0044] In the S1 step, the brick body 1 is fired at a temperature of 800 degrees Celsius inside the brick kiln, and the firing time is 4.5 hours.

[0045] Others are the same as embodiment 1.

Embodiment 3

[0047] The difference between this embodiment and embodiment 1 is that;

[0048] The depth of the repair groove is 90 cm.

[0049] The thickness of the reinforcement layer 13 is 8 cm

[0050] The thickness of the brick body 2 is 4 centimeters, and the width and length of the brick body 2 are both 20 centimeters;

[0051] In the S1 step, the brick body 1 is fired at a temperature of 900 degrees Celsius inside the brick kiln, and the firing time is 4 hours.

[0052] Others are the same as embodiment 1.

[0053] Working principle: During the laying of the brick body 2, since the arc-shaped ends of the two adjacent brick bodies 2 are matched with the arc-shaped limiting groove 5, the fixing bolt 6 is passed through the adjacent brick body 2. The installation hole 1 and the limit hole 4 make the two adjacent brick bodies 2 closely match each other to form an isolation layer 12. The isolation layer 12 is used to block the capillary action of the soil on the groundwater and preven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com