Polyurethane three-dimensional reinforced GMT (glass fiber mat reinforced thermoplastics) composite board and preparation method thereof

A composite board and polyurethane technology, which is applied in the field of fiber-reinforced thermoplastic resin composite materials, can solve the problems of large amount of hot-melt fibers, high cost, and contradictory mechanical properties, and achieve the goals of reducing material quality, improving sound-absorbing performance, and improving mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Select different thicknesses and weights of felts to test the uniformity of the PU foaming solution (due to the uniformity of the test, the final product does not need to enter the composite machine for foaming), the specific plan is as follows:

[0029] The preferred ratio of raw materials is selected as follows:

[0030] 1. The mass fraction of GMT felt accounts for 70% of the whole material. GMT felt is mainly composed of 60% polypropylene fiber by mass fraction and 40% glass fiber by mass fraction. The weight of GMT felt is 700g / m 2 , The thickness is 2, 3, 10, 20, 21mm respectively.

[0031] 2. The mass fraction of GMT felt is 70% of the whole material. GMT felt is mainly composed of 60% polypropylene fiber and 40% glass fiber. The thickness of GMT felt is 6mm, and the weight is 150, 200, 2000, 3000, 3100g / m 2 .

[0032] The semi-rigid foam foaming liquid accounts for 30% of the mass fraction of the whole material. The delay catalyst content in material A is 0, ...

Embodiment 2

[0040] Select different ratios of GMT and PU foaming liquid to test the effect of introducing process and uniformity of PU foaming liquid (due to the uniformity effect of the test, the final product does not need to enter the composite machine for foaming), the specific plan is as follows:

[0041] The preferred ratio of raw materials is selected as follows:

[0042] The mass fractions of GMT felt in the entire material are 19%, 20%, 50%, 90%, and 91% respectively; GMT felt is mainly composed of 60% polypropylene fiber and 40% glass fiber by mass fraction, and the weight of GMT felt is 1000g / m 2 , and the thickness is 10mm respectively.

[0043] The mass fraction of the corresponding high-resilience foaming liquid is 81%, 80%, 50%, 10%, and 9%, wherein the delay catalyst content in material A is 0, and the additive content is 0. Material A includes polyether polyol, crosslinking agent, foaming agent, foam stabilizer, and auxiliary agent, and material B includes isocyanate. ...

Embodiment 3

[0049] The selection of raw material ratio is as follows: GMT composite board includes GMT felt and PU foaming liquid as the base. The mass fraction of GMT felt is 70% of the whole material. GMT felt is mainly composed of 60% polypropylene fiber and 40% glass fiber. The thickness of GMT felt is 6mm, and the weight is 700g / m 2 . The mass fraction of the hard foam foaming liquid in the whole material is 30%. The delay catalyst content in material A is 0, and the additive content is 0. Material A includes polyether polyol, crosslinking agent, foaming agent, foam stabilizer, and auxiliary agent, and material B includes isocyanate.

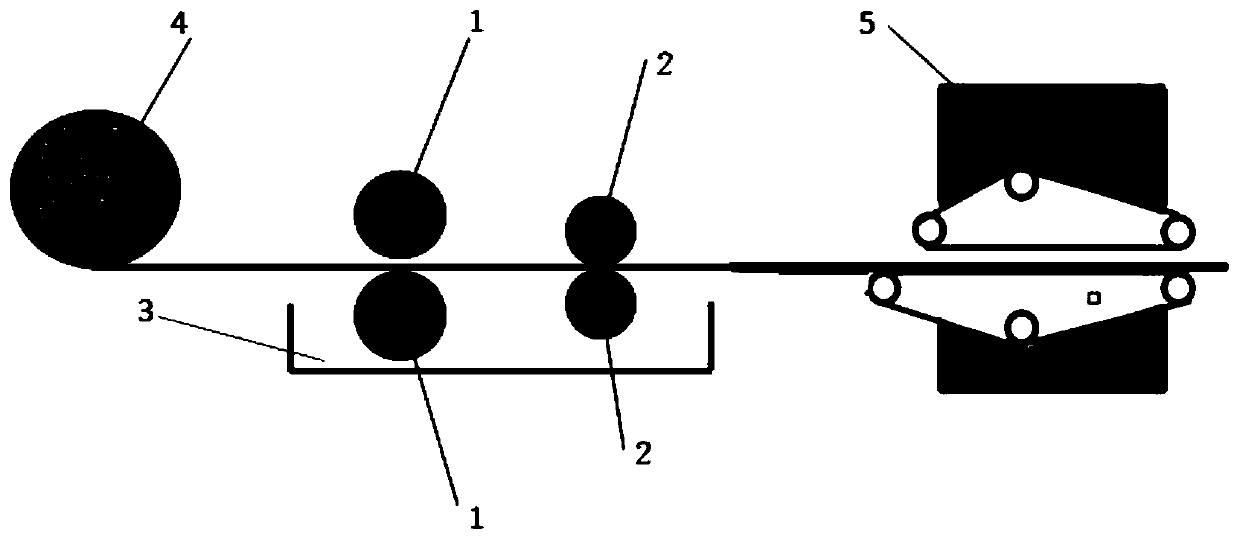

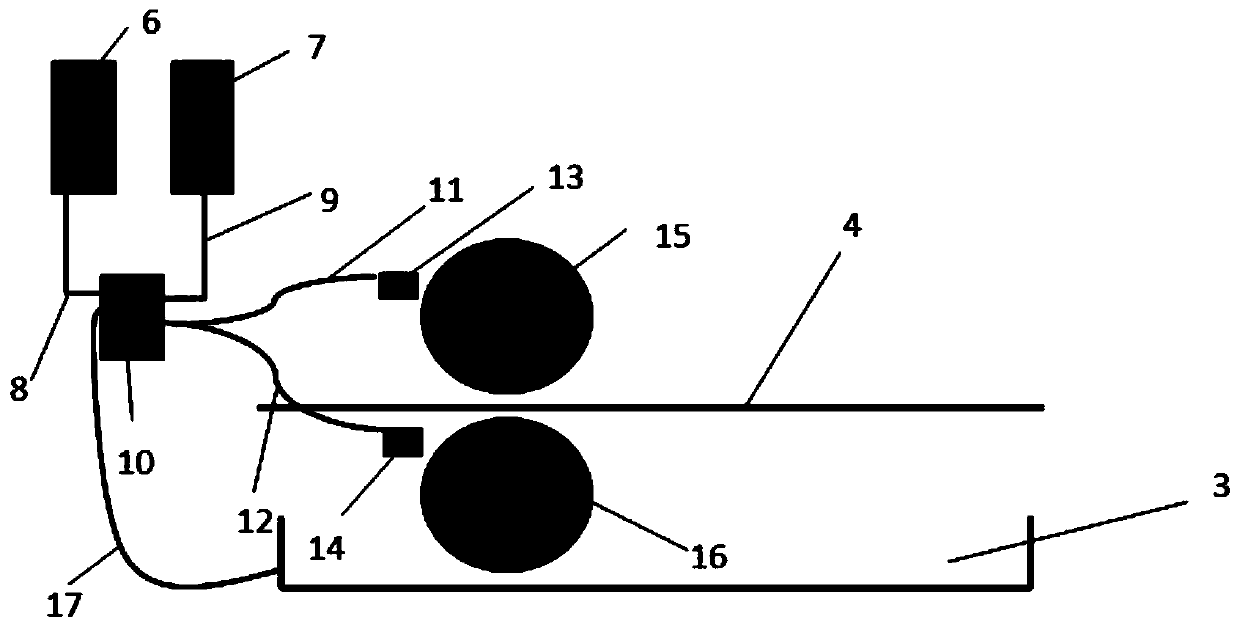

[0050] The preferred preparation method is as follows: mix hard foam material A and material B in the mixing chamber of material A and material B at a ratio of 1:2.7, and the mixed solution is sprayed to the upper rubber roller and the lower rubber roller through the roller nozzle respectively, and the amount of glue sprayed is 25g / s; the rubber rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com