Water-soluble quaternary ammonium salt fluorescent monomer, fluorescent polymer and their preparation methods

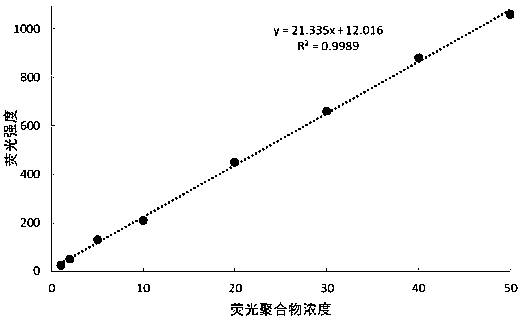

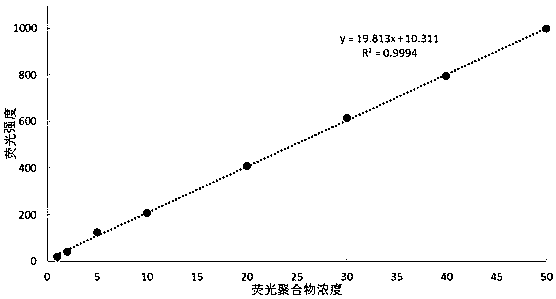

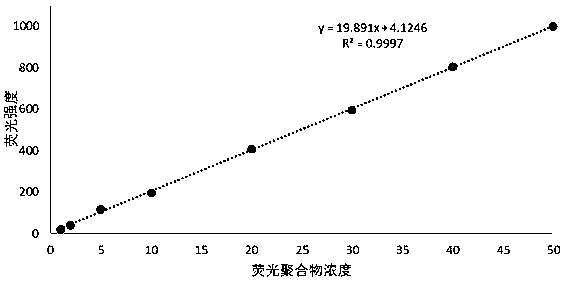

A fluorescent polymer and fluorescent monomer technology, applied to fluorescent polymers, can solve the problems of high initial polymer stability and harsh reaction conditions, and achieve the effects of high double bond activity, simple preparation method, and accurate concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: Preparation of fluorescent monomer NGA

[0042] (1) Weigh 16.7g of 4-bromo-1,8-naphthalic anhydride and 18.5g of N',N'-dimethylaminopropylamine, measure 100mL of methanol, and place it in a In a four-neck flask, under argon protection, start stirring, add 16.2g of solid sodium methoxide, monitor the reaction progress with TLC, react at room temperature for 10h until the end of the reaction, adjust the pH of the system to 10.5 with hydrochloric acid, and obtain 4-methoxy- N-(3-N', N'-dimethylaminopropyl) naphthalimide solution for subsequent use;

[0043] (2) Weigh 23.0g glycidyl acrylate, 100ppm 4-methoxyphenol and 50mL water, add to the solution obtained in step (1), under the protection of argon, start stirring, monitor the reaction process with TLC, react at room temperature After 24 hours to the end of the reaction, methanol was recovered by distillation under reduced pressure to obtain a red viscous crude product, which was recrystallized with ethano...

Embodiment 2

[0046] Embodiment 2: Preparation of fluorescent monomer NGA

[0047] (1) Weigh 13.9g of 4-bromo-1,8-naphthalic anhydride and 15.5g of N',N'-dimethylaminopropylamine, measure 100mL of DMSO, and place it in a In a four-neck flask, under the protection of argon, stir and heat up to 50°C, add 13.5g of solid sodium methoxide, monitor the reaction progress with TLC, heat and stir for 5h until the reaction is complete, adjust the pH of the system to 9.5 with hydrochloric acid, and obtain 4- Methoxy-N-(3-N', N'-dimethylaminopropyl) naphthalimide solution for standby;

[0048] (2) Weigh 13.5g glycidyl acrylate, 1000ppm 4-methoxyphenol and 100mL water, add to the solution obtained in step (1), under argon protection, stir and heat up to 50°C, monitor the reaction process with TLC , heated and stirred for 8h to the end of the reaction, and the DMSO solvent was recovered by distillation under reduced pressure to obtain a red viscous crude product, which was recrystallized with ethanol / et...

Embodiment 3

[0049] Embodiment 3: Preparation of fluorescent monomer NGMA

[0050] (1) Weigh 13.8g of 4-bromo-1,8-naphthalic anhydride and 30.7g of N',N'-dimethylaminopropylamine, measure 50mL of methanol, and place it in a place equipped with a condenser, thermometer and stirrer In a four-neck flask, under argon protection, start stirring and heat up to 45°C, add 45g of 30% sodium methoxide methanol solution, monitor the reaction process with TLC, stir and heat for 3h until the reaction is over, adjust the pH of the system with hydrochloric acid = 10.0 to obtain 4-methoxy-N-(3-N', N'-dimethylaminopropyl) naphthalimide solution for subsequent use;

[0051] (2) Weigh 21.3g glycidyl methacrylate, measure 500ppm 4-methoxyphenol and 10mL water, add to the solution obtained in step (1), stir at room temperature under the protection of argon, and monitor the reaction with TLC Process, stirred for 24 hours until the reaction was completed, and the methanol was recovered by distillation under red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com